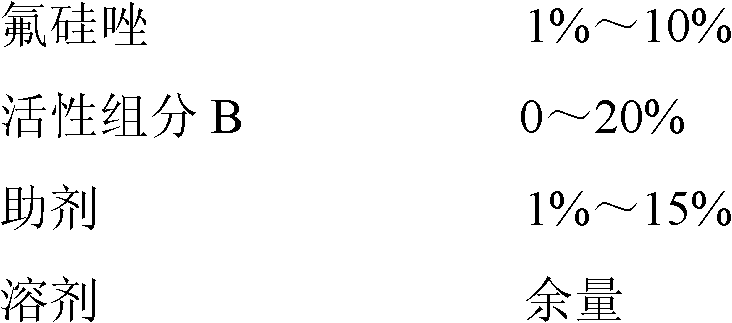

Ultralow-volume solvent containing Flusilazole

A technology of ultra-low volume liquid agent and fluorine-containing silazole, applied in the field of pesticides, can solve problems such as adhesion, wettability, poor permeability, difficulty in meeting large-scale planting, and inability to achieve control effects, so as to improve drug efficacy , expanding the target spectrum of prevention and treatment, and reducing the effect of medication times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

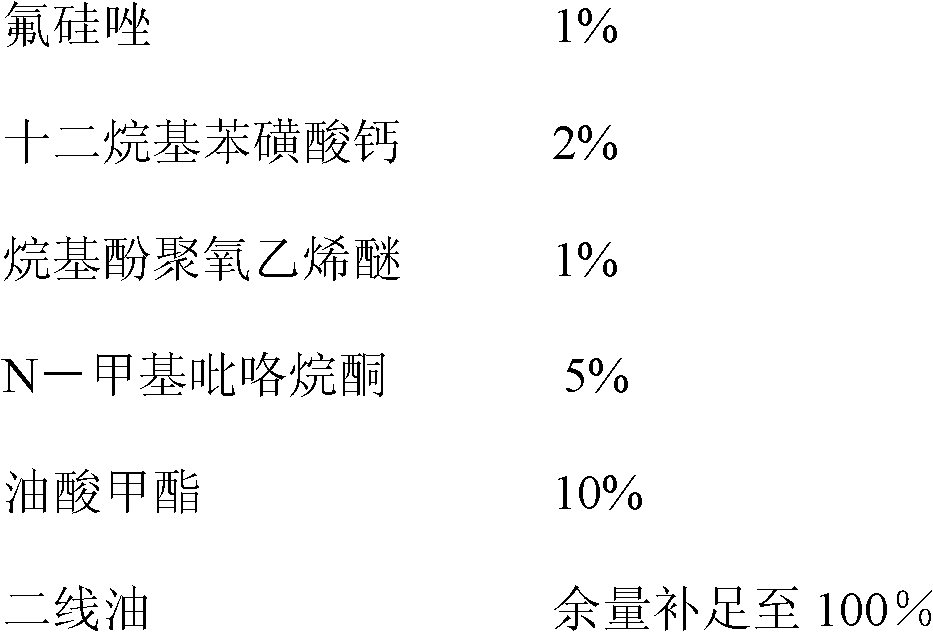

example 1

[0046] 1% flusilazole ultra-low volume solution

[0047] According to the following weight ratio:

[0048]

[0049] Preparation method: In a reaction vessel with electric stirring, under normal temperature and pressure, first stir and dissolve the active ingredient flusilazole with a solvent according to the formula ratio, the stirring speed is controlled at 60 rpm, then add the auxiliary ingredients, and fully stir for 60 minutes and make it mix evenly to obtain 1% flusilazole ultra-low volume liquid.

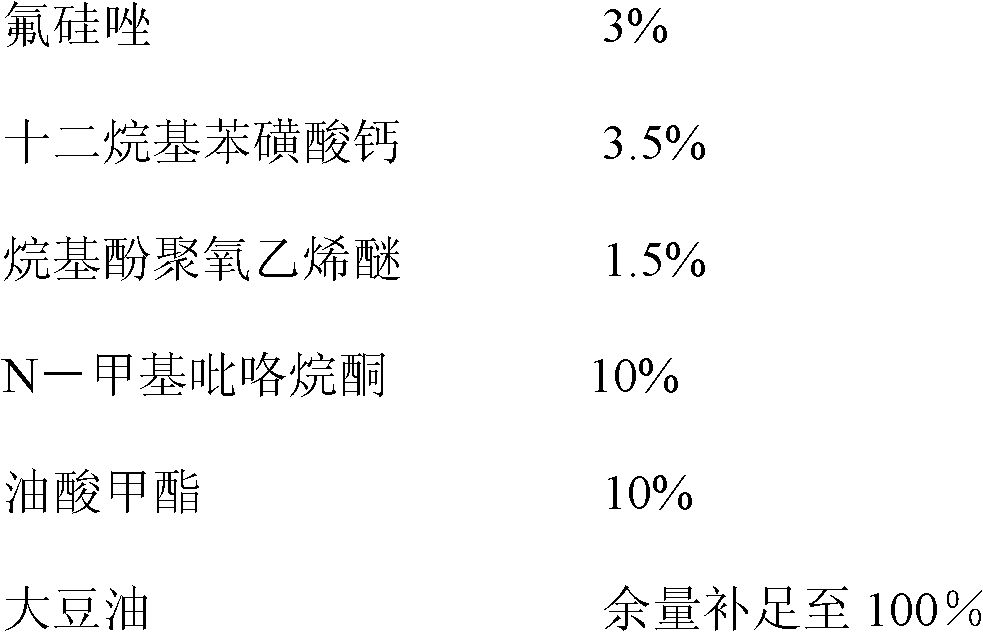

example 2

[0051] 3% flusilazole ultra-low volume solution

[0052] According to the following weight ratio:

[0053]

[0054] Preparation method: In a reaction vessel with electric stirring, stir and dissolve the active ingredient flusilazole with a solvent according to the formula ratio at room temperature, and control the stirring speed at 120 rpm, then add auxiliary ingredients, and stir thoroughly for 30 minutes to make Mix them uniformly to obtain a 3% flusilazole ultra-low volume liquid.

example 3

[0056] 6% flusilazole ultra-low volume solution

[0057] According to the following weight ratio:

[0058]

[0059] Preparation method: In a reaction vessel with electric stirring, first stir and dissolve the active ingredient flusilazole with a solvent according to the formula ratio at room temperature, control the stirring speed at 100 rpm, then add the auxiliary ingredients, and stir thoroughly for 45 minutes to make Mix them uniformly to obtain a 6% flusilazole ultra-low volume liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com