Method for separating and purifying chlorogenic acid from eucommia ulmoides leaves

A technology of chlorogenic acid and eucommia leaves, which is applied in the field of steam explosion-assisted extraction of chlorogenic acid in eucommia leaves and separation and purification of chlorogenic acid, which can solve the problems of unstable structure of catechol, easy oxidation and decomposition, etc., and achieve treatment The effect of short time, improving extraction rate and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

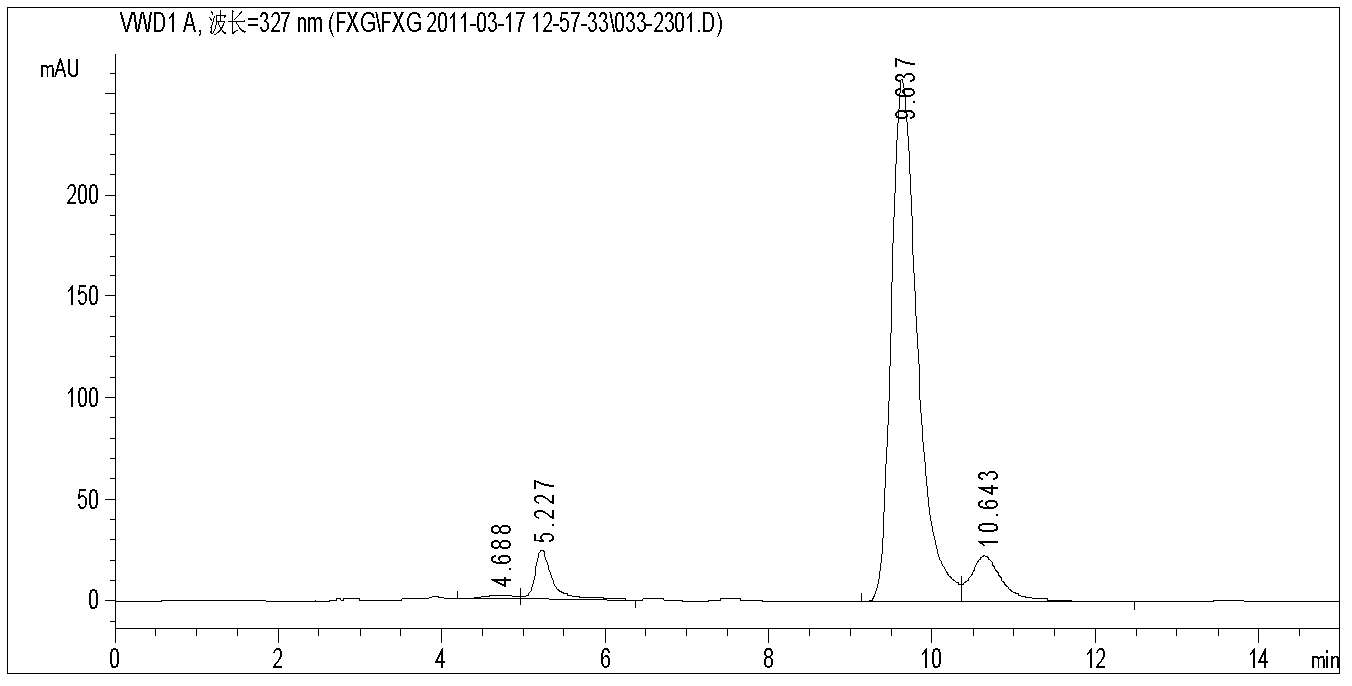

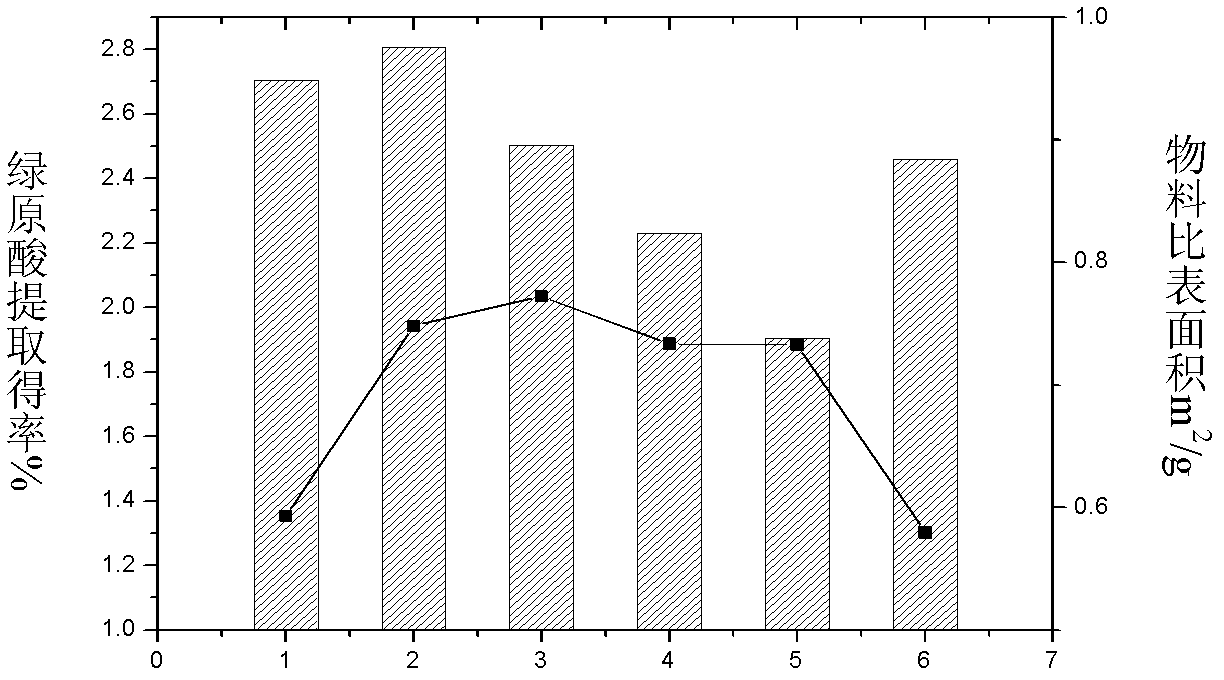

Embodiment 1

[0028] Take 500g of Eucommia ulmoides leaf medicinal materials, add eucommia ulmoides leaf medicinal materials to acidic water (pH adjusted to 3.5 by acetic acid) in a ratio of 1:1 by mass of absolute dry medicinal materials to acidic water, and then soak for 30min at room temperature; place the soaked materials In the steam explosion tank, first pass air and then liquid nitrogen to make the temperature in the tank reach 100°C, maintain it for 3 minutes, and then perform steam explosion treatment; add the steam explosion treatment material or the conventionally crushed material to 40 mesh into it. 3 times the weight of water, extract 3 times at 60°C, 60 min each time, combine the extracts; concentrate the extracts under reduced pressure, add 3 times the concentrated liquid ethyl acetate and extract twice to obtain the ethyl acetate layer, to which 5 %NaOH liquid neutralization makes the chlorogenic acid in ethyl acetate enter the water phase. After the water phase is separated, ...

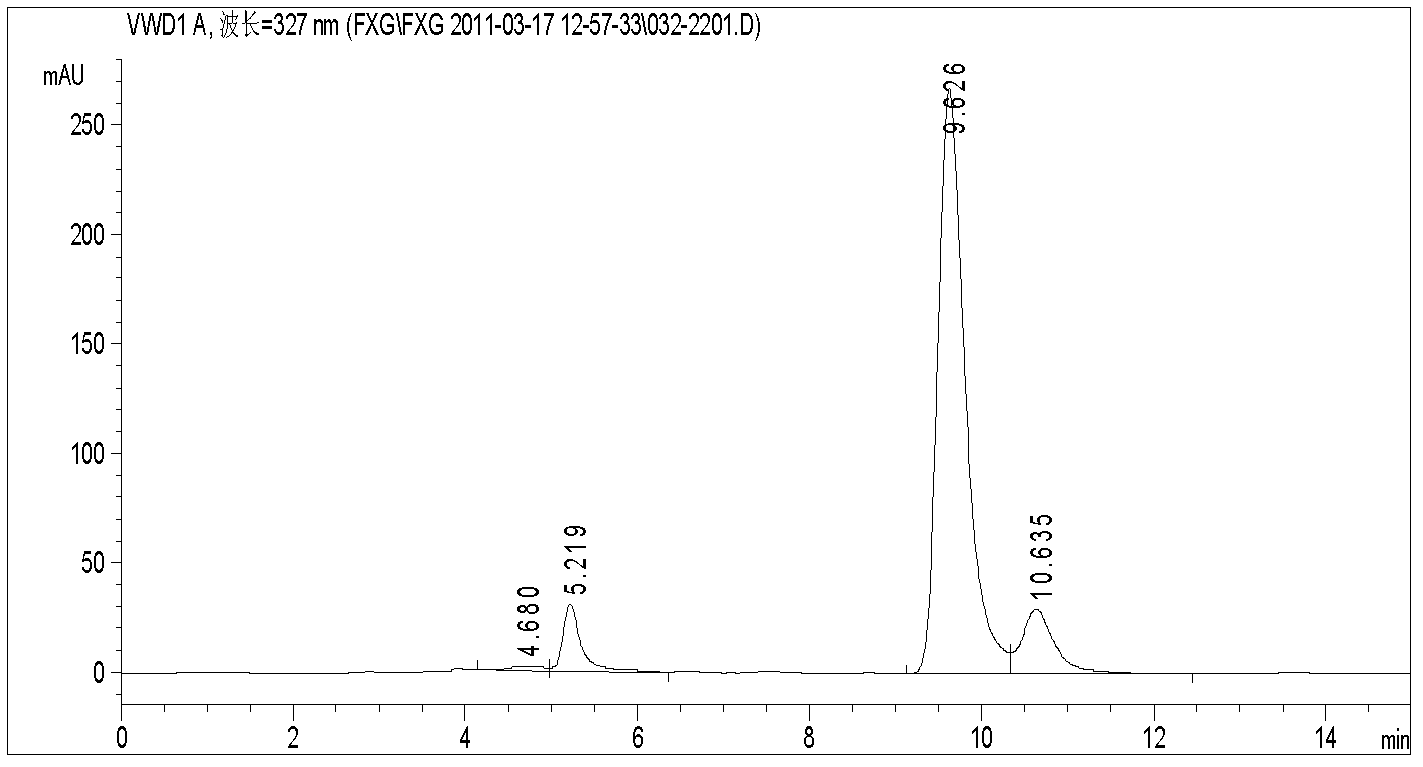

Embodiment 2

[0030] Take 500g of Eucommia ulmoides leaf medicinal material, add eucommia ulmoides leaf medicinal material to acidic water (pH is adjusted to 3.0 by hydrochloric acid) in a ratio of 1:2 by mass of absolute dry medicinal material and acidic water, and then soak for 60min at room temperature; place the soaked material Put carbon dioxide into the steam explosion tank, make the temperature in the tank reach 80℃, maintain it for 15 minutes, then proceed with steam explosion treatment; add the material after steam explosion treatment or the conventionally crushed material to 40 mesh into water 5 times its absolute dry weight. Extract 3 times at 40°C for 50 minutes each time, combine the extracts; concentrate the extracts under reduced pressure, add 3 times the concentrated solution of ethyl acetate and extract twice to obtain the ethyl acetate layer, which is added with 3% NaOH solution to neutralize the acetic acid The chlorogenic acid in the ethyl ester enters the water phase. Aft...

Embodiment 3

[0032] Take 500g of Eucommia ulmoides leaf medicinal material, add eucommia ulmoides leaf medicinal material to acidic water (pH 2.0 adjusted by sulfuric acid) in a ratio of 1:3 by mass of absolutely dry medicinal material and acidic water, and then soak for 5min at room temperature; place the soaked material in In the steam explosion tank, pass nitrogen first, then liquid nitrogen, so that the temperature in the tank reaches 75℃, maintain it for 10 minutes, and then perform steam explosion treatment; add the material after steam explosion treatment or the conventionally crushed material to 40 mesh into its absolute dryness 10 times the weight of water was extracted 3 times at 80°C for 30 minutes each time, and the extracts were combined; the extracts were concentrated under reduced pressure, and 3.5 times the ethyl acetate of the concentrated solution was added for extraction twice to obtain an ethyl acetate layer. %NaOH liquid neutralization makes the chlorogenic acid in ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com