Silk fibroin porous material and preparation method thereof and tissue engineering stent

A silk fibroin and porous material technology, applied in the field of materials, can solve the problems of small pore size, application limitations, unfavorable drug loading, etc., and achieve the effect of inhibiting the formation of sheet structure and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention discloses a preparation method of a silk fibroin porous material, which comprises the following steps:

[0031] drying the silk fibroin aqueous solution into a silk fibroin film, and dissolving the silk fibroin film in water;

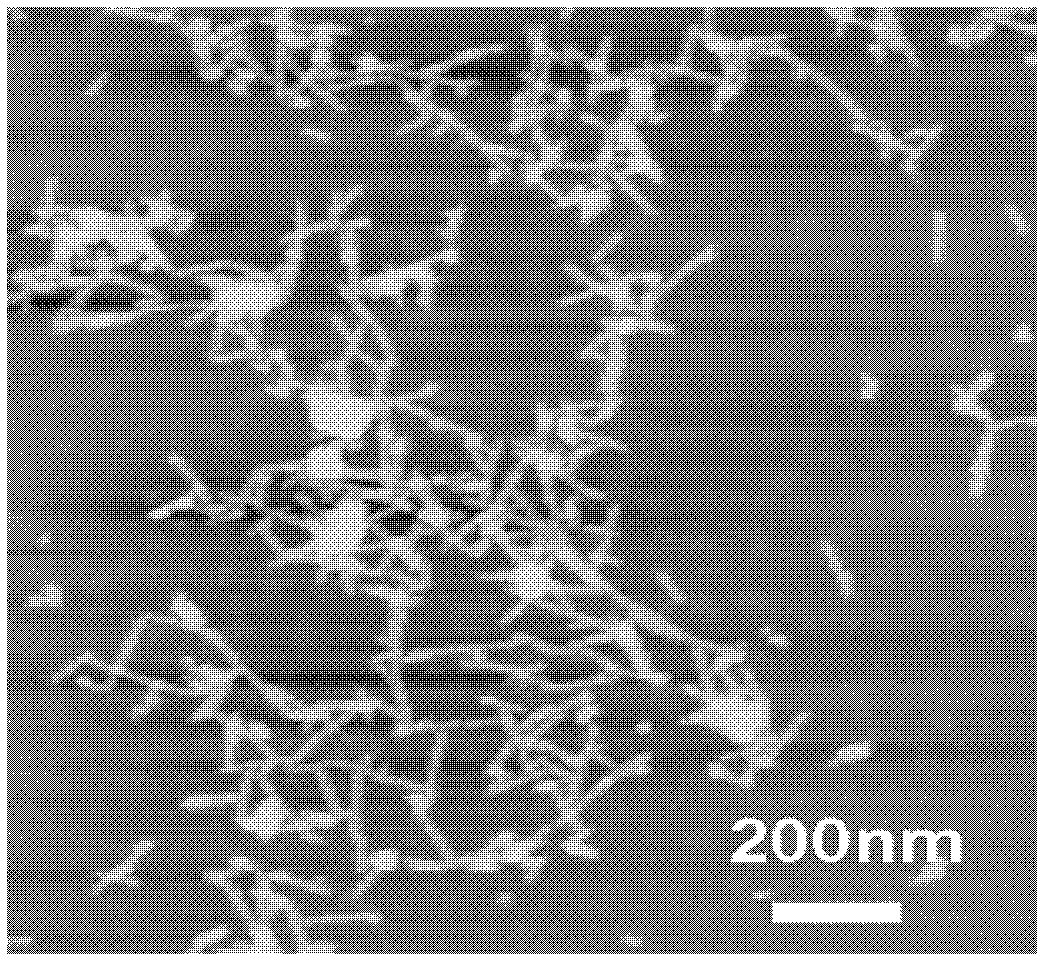

[0032] Repeat the drying-dissolving process to obtain the silk fibroin nanowire aqueous solution;

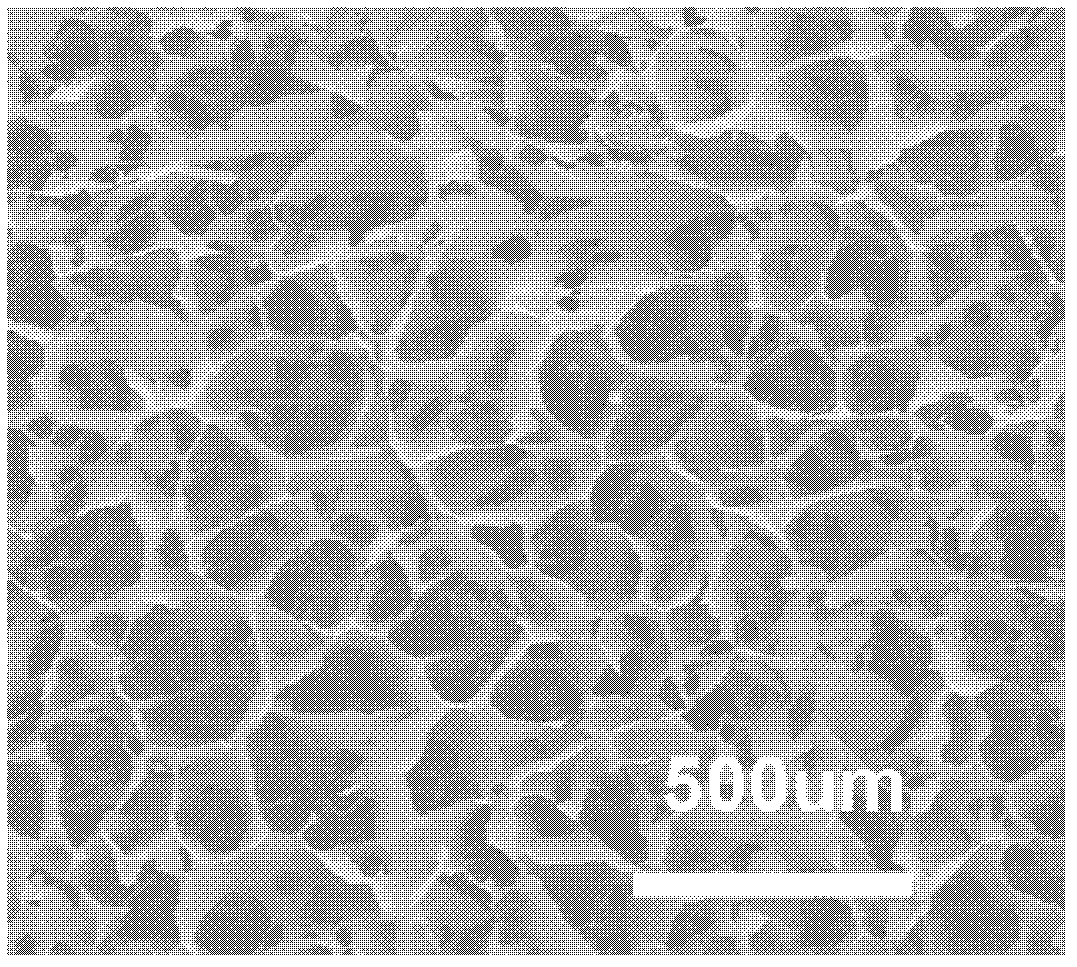

[0033] Freeze-drying the silk fibroin nanowire aqueous solution to obtain a silk fibroin material precursor;

[0034] The silk fibroin material precursor is subjected to alcohol treatment, vacuum water treatment or stretching treatment, and the silk fibroin porous material is obtained after drying.

[0035] In the above preparation process, the present invention uses silk fibroin aqueous solution as raw material, utilizes the self-assembly behavior of silk fibroin to regulate the nanostructure, freeze-dries after multiple drying-dissolving processes, and then undergoes alcohol treatment, vacuum water treatment or The silk fibroin po...

Embodiment approach

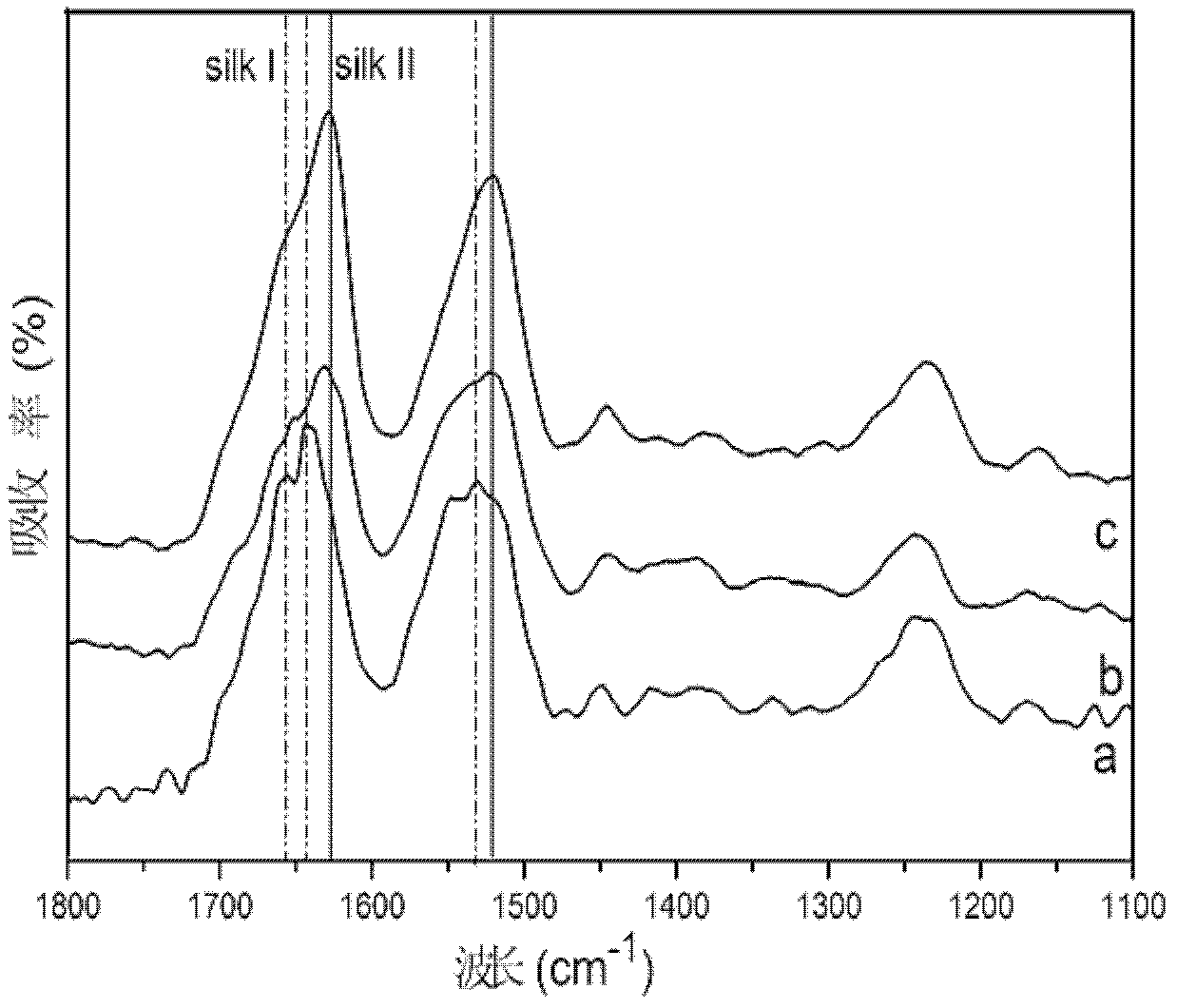

[0042] In addition, the present invention also includes the step of subjecting the porous silk fibroin material to alcohol treatment, vacuum water treatment or stretching treatment, the purpose of which is to adjust the nanocrystalline structure of the silk fibroin porous material, thereby obtaining different degradation properties and Mechanical properties to meet the requirements of different tissue regeneration or different drug release. The alcohol treatment, vacuum water treatment or stretching treatment can make the prepared silk fibroin porous material insoluble in water and the like. In addition, by adjusting the conditions of alcohol treatment or vacuum water treatment, such as the choice of alcohol, etc., the secondary structure and stability in the prepared silk fibroin porous material can be adjusted, thereby adjusting the nanocrystalline structure of the silk fibroin porous material, A Silk I and / or Silk II structure is obtained. The alcohol used in the alcohol t...

Embodiment 1

[0047] 50g silk in 0.5% Na 2 CO 3 Boil in the solution for 60 minutes at 100°C to remove the sericin protein on the outside of the silk, wash it with deionized water, repeat the above operation 3 times, and dry the silk at 60°C; weigh 15g of the degummed silk after the above treatment and dissolve it in 100mL with a concentration of 9.3 mol / L LiBr solution, dissolved at 60°C for 4 hours, and then immersed in deionized water for 3 days with a dialysis bag with a molecular weight cut-off of 3500. During this period, the water was changed every two hours to remove LiBr in the solution, thereby obtaining pure Silk fibroin solution, its concentration is 6%;

[0048] Take 15ml of the above solution and put it into a polyethylene petri dish, and dry it at room temperature to form a film under the condition that the humidity is 40%. The drying time is 24 hours. The obtained silk fibroin film is dissolved in 15ml of deionized water to obtain a dissolved film solution; re-inject the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com