Closed-loop controlled-pressure well drilling system

A managed pressure drilling and control system technology, applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problems of unfavorable popularization and application, waste of manual throttling manifold, high selectivity and dependence, etc. Achieve the effects of avoiding repeated installation of sensors, convenient on-site application, and strong system adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

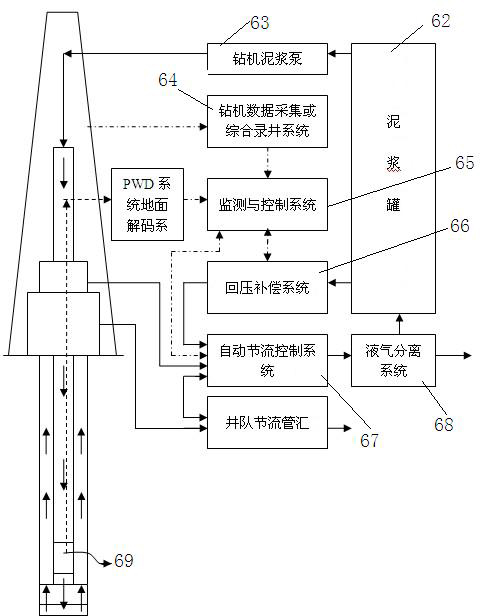

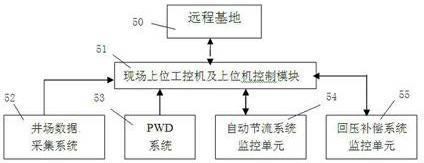

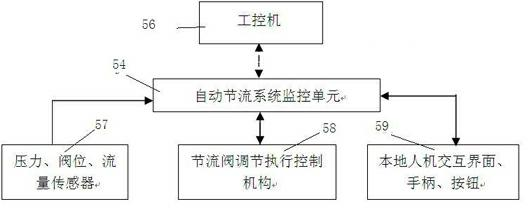

[0059] A closed-loop pressure-controlled drilling system, including an annular pressure monitoring system, a rotary control head, and a liquid-gas separation system, and also includes a monitoring and control system, an automatic throttling control system, and a back pressure compensation system. The flow control system is connected to the back pressure compensation system; the monitoring and control system includes an upper industrial control detection mechanism, an automatic throttling system monitoring unit and a back pressure compensation system monitoring unit, and the upper industrial control detection mechanism is connected with the automatic throttling system monitoring unit respectively Connect with the monitoring unit of the back pressure compensation system.

[0060] The monitoring and control system among the present invention is described below:

[0061] The upper industrial control monitoring mechanism includes an industrial computer, a network communication devi...

Embodiment 2

[0087] The present invention is described in detail below:

[0088] 1. The specific implementation steps of the closed-loop pressure control drilling system are as follows:

[0089] 1) The upper industrial control detection mechanism includes: industrial computer, network communication equipment and communication interface, industrial computer and well site data acquisition system local area network, PWD system ground decoding software. The industrial computer establishes an industrial local area network through network communication equipment. The interface is respectively connected with the monitoring unit of the automatic throttling system and the monitoring unit of the back pressure compensation system; the well site data acquisition system mainly includes the integrated mud logging system and the data acquisition and monitoring system of the drilling rig itself; through the network interface and the host computer software and interface, it can Real-time sharing of enginee...

Embodiment 3

[0118] The automatic throttling control system in the present invention can also be a hydraulically controlled automatic throttling control system, and the following describes the use of a hydraulically controlled automatic throttling control system:

[0119] The hydraulic control automatic throttling control system includes automatic throttling manifold, electric hydraulic throttling control actuator and monitoring control system:

[0120] The throttling manifold mainly includes: three automatic throttling control channels, consisting of three hydraulically controlled throttling devices and six plate valves, one emergency manual throttling control channel, consisting of one throttle valve and two plate valves The emergency pressure relief straight channel is composed of a flat valve, and there are two parallel channels in front of the outlet, which are composed of three flat valves and U-shaped outlet flowmeters. The four channels are connected in parallel to form a set of thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com