Pre-treatment method for liquid desulfurizer solution of flue gas, and detection method thereof

A detection method and desulfurization agent technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as unusable use, increase of interference factors, separation and extraction of desulfurizers, etc., so as to reduce the impact, shorten the detection period, and avoid hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Pretreatment of Acidic Precipitation Liquid Desulfurizer Solution

[0028] Measure 250mL of acidic precipitation into a 500mL beaker, place it on a hot plate and heat it to boil directly at high temperature, quickly evaporate a large amount of water to remove water, and concentrate to a solution volume of about 5mL. While hot, add concentrated ammonia water dropwise to adjust the pH value to 9.5, continue to boil for 4 minutes, adjust the volume to 10 mL with water, and dry filter to prepare a liquid desulfurizer detection solution for acidic precipitation.

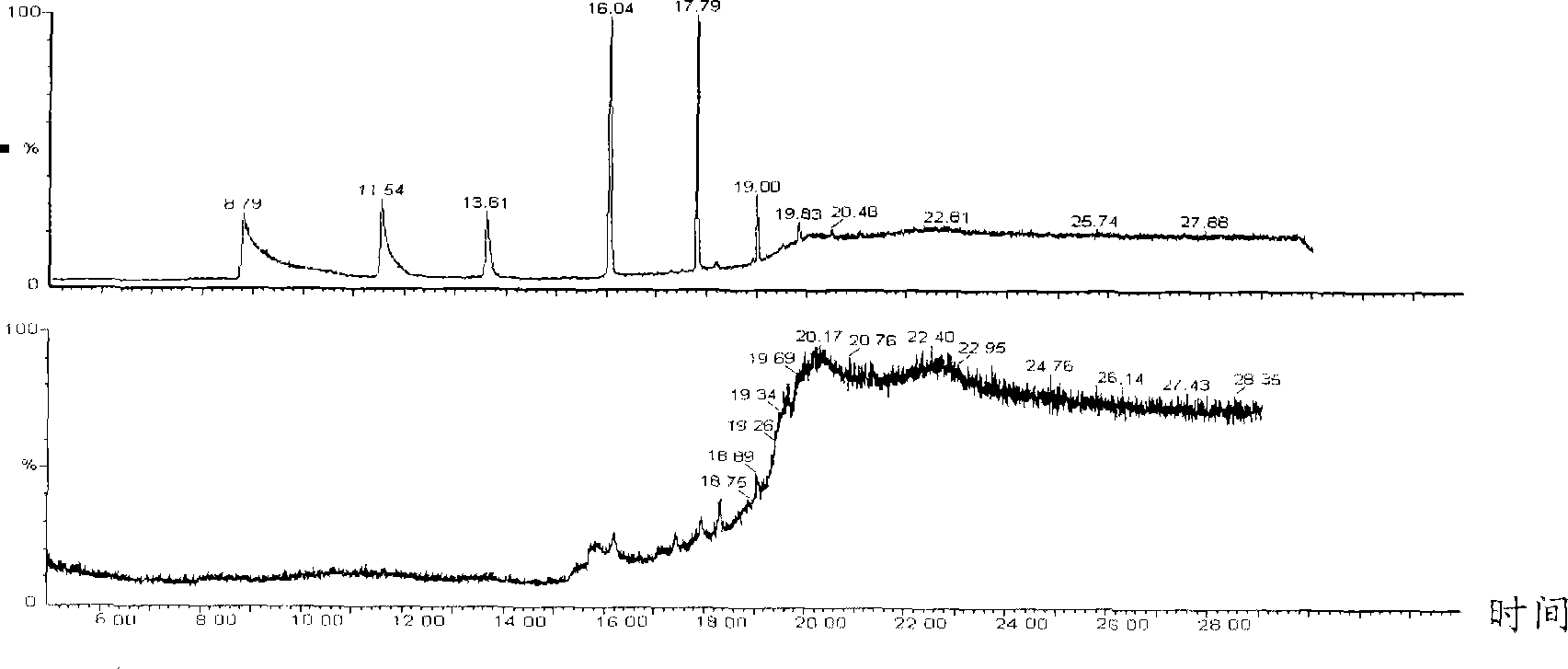

[0029]Detecting Organic Components of Desulfurizer in Liquid Desulfurizer Solution by GC-MS

[0030] The organic components of the desulfurizer in the prepared acidic precipitation liquid desulfurizer solution were determined by GC-MS. The GC-MS measurement procedure was carried out in a conventional manner. Among them, chromatographic parameters: injection volume (15 microliters); injection port temperature (300...

example 2

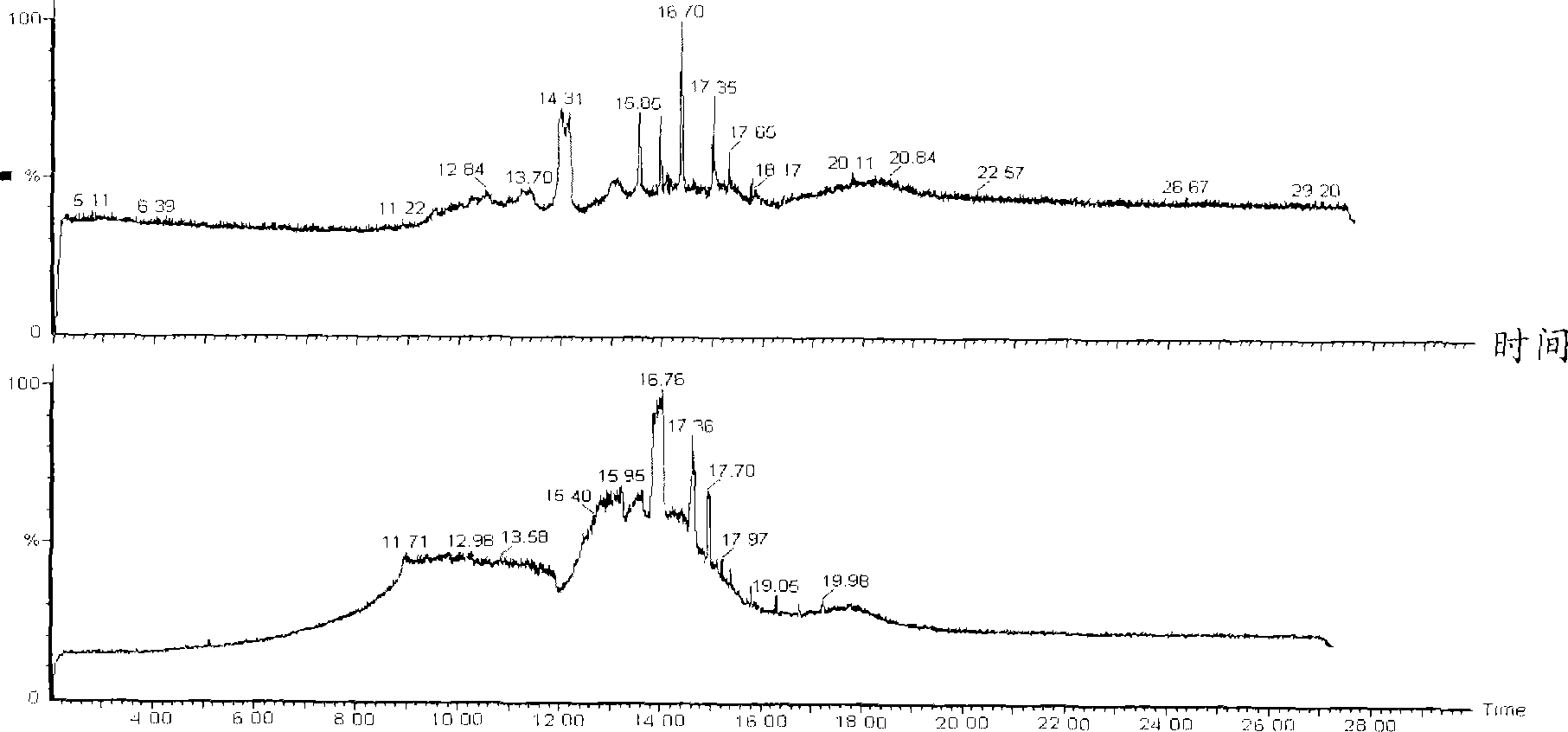

[0033] Measure 350mL of flue gas condensed water, concentrate to a volume of about 8mL, adjust pH=8.5, continue to boil for 5 minutes, dilute to 15mL with water, and centrifuge to separate insoluble solids. Besides, the liquid desulfurizer solution was prepared in the same manner as in Example 1 and detected by GC-MS.

[0034] figure 2 The upper curve in the figure shows the analysis results of pretreatment and detection of "flue gas condensate" according to Example 2; figure 2 The lower curve in the figure shows the analysis results without pretreatment of the "flue gas condensate", but with direct detection.

example 3

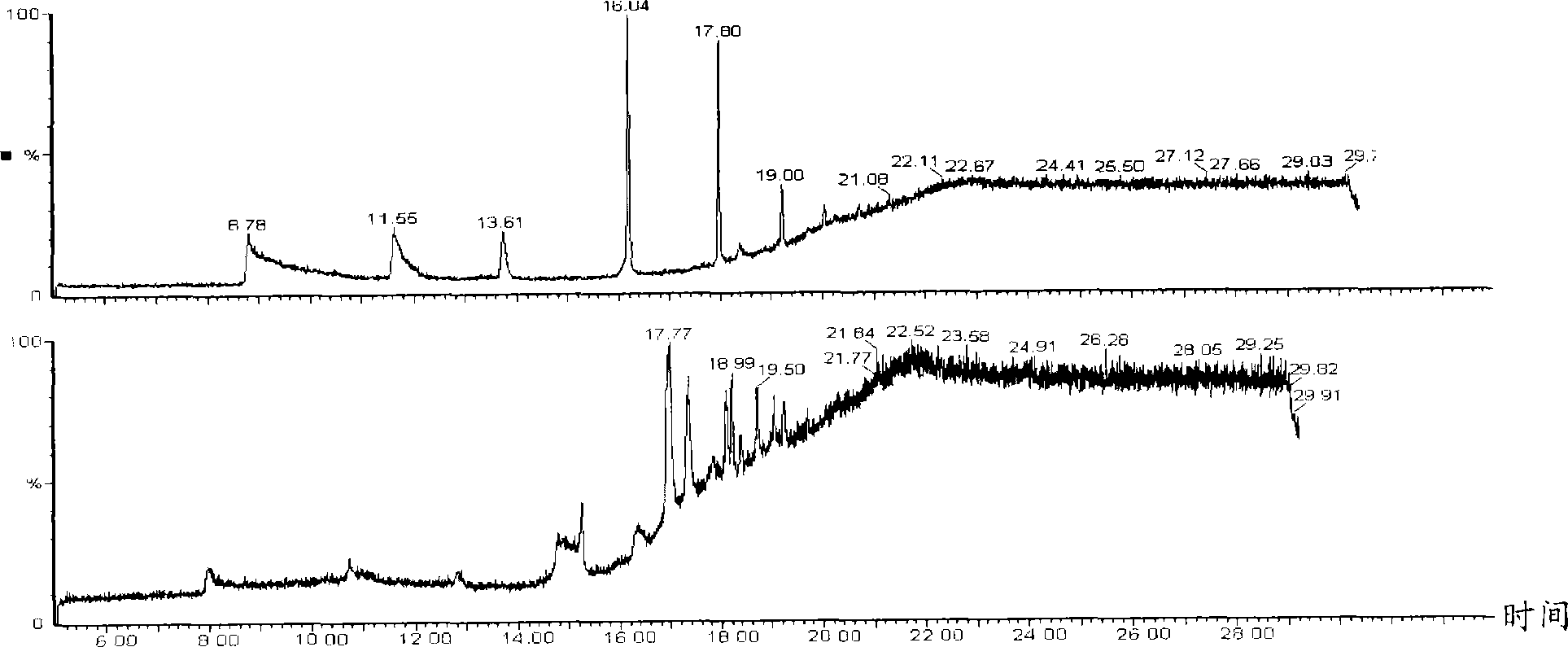

[0036] Measure 450mL of washing water, concentrate to a volume of about 5mL, adjust the pH to 7.5, continue to boil for 3 minutes, dilute the water to 10mL, and dry filter to separate the solid substance. Besides, the liquid desulfurizer solution was prepared in the same manner as in Example 1 and detected by GC-MS.

[0037] image 3 The upper curve in the figure shows the analysis results of pretreatment and detection of "wash water" according to Example 3; image 3 The lower curve in the figure shows the results of the analysis where the "wash water" was not pretreated, but was directly detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com