Method for manufacturing laser chip for water vapor detection

A manufacturing method and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of increased optical loss and decreased laser performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

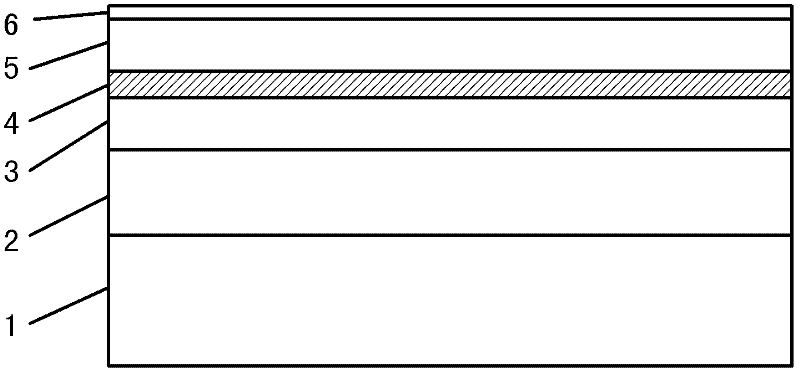

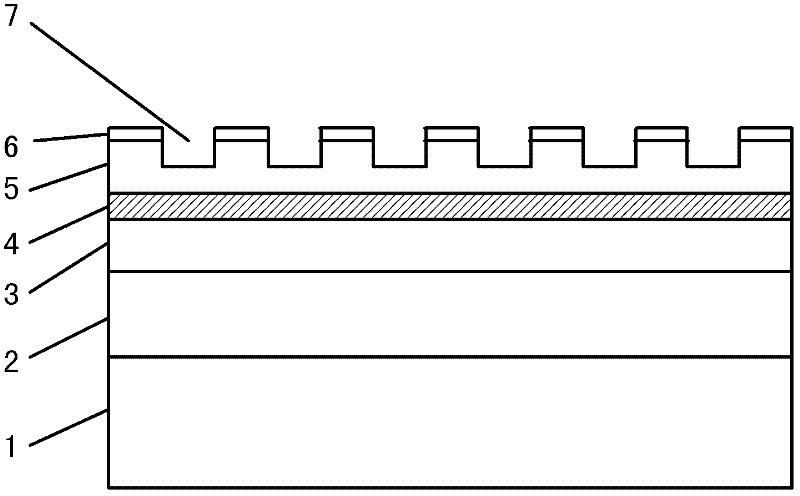

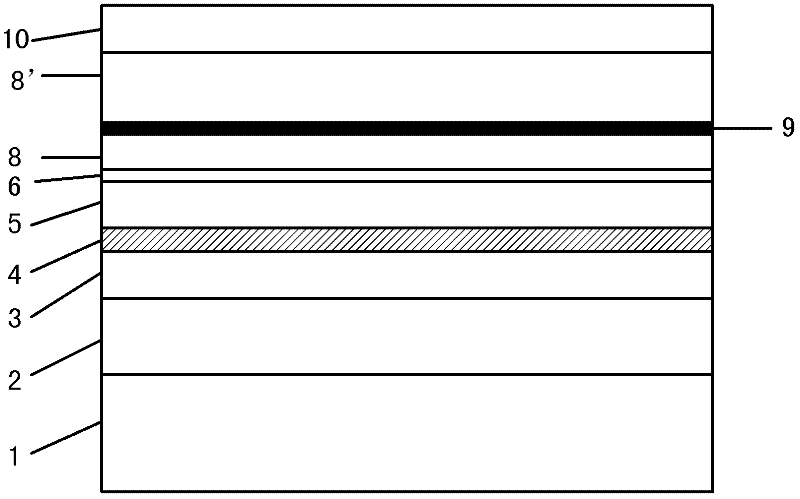

[0023] See Figure 1 to Figure 6 , The manufacturing method of the laser chip for water vapor detection of the present invention, the specific implementation steps are as follows:

[0024] Step 1: Using low pressure metal organic chemical vapor deposition (LP-MOCVD), the InP buffer layer 2, the lower waveguide layer 3, and the multiple quantum well structure are sequentially grown on the (001) surface of the n-InP substrate 1 in the same epitaxy 4. The upper waveguide layer 5 and the pn inversion layer 6;

[0025] Among them, the growth temperature used in the low-pressure metal organic metal organic chemical vapor epitaxy growth is 655° C., and the growth pressure is 22 mbar. This method has low cost and is suitable for large-scale production;

[0026] Wherein, the thickness of the InP buffer layer 2 is 1 μm, and the doping concentration is 1×10 18 / cm 3 ;

[0027] Wherein, the compressively strained quantum well material in the multiple quantum well structure 4 is InGaAs, the strai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com