Method for preparing lucid ganoderma mycelium liquid from slag water generated in production of starch

A technology of Ganoderma lucidum mycelium and starch, which is applied in the directions of botanical equipment and methods, application, fertilizer mixture, etc., can solve the problems of many raw material components of liquid fermentation medium, can not save energy and manpower, complex production process, etc., and achieves reduction of raw materials. The process of preparation and high temperature steam sterilization, the effect of saving energy and manpower, and the value of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

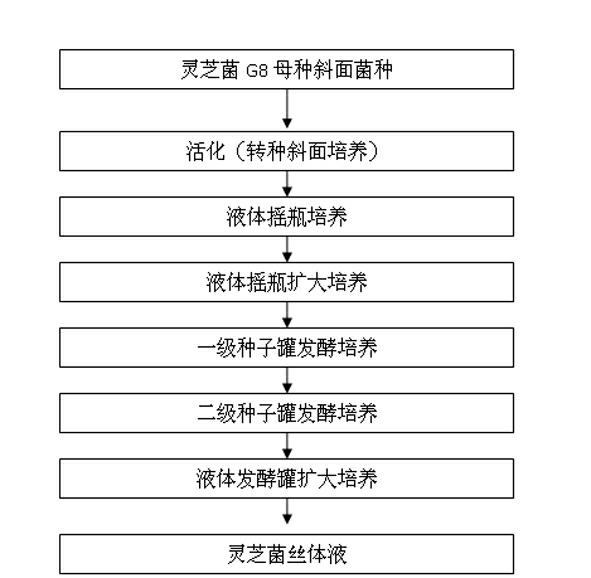

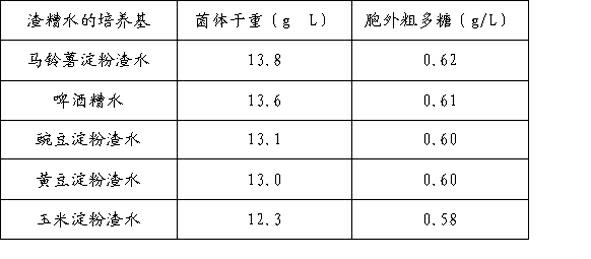

[0027] Example 1: see figure 1 , the method for preparing ganoderma lucidum mycelium fluid with the slag water produced by producing potato starch as a medium, its main feature is that the preparation steps are:

[0028] (1) Preparation of Ganoderma lucidum slant strains: Inoculate the ganoderma lucidum mycelium block in the mother seed test tube slant surface on the slag water agar slant medium produced by potato starch production, and activate it by static culture at 24-26°C for 4-6 days. Then replant it on the slack-water sawdust agar slant medium produced by the production of potato starch, and carry out the second activation by static culture at 24-26°C for 4-6 days, and it is a first-class strain;

[0029] The slag water agar slant medium produced by the production of potato starch: add 1.8 g of glucose and 1.8 g of agar to 80 ml of slag water produced by the production of potato starch, and the pH value is natural. Minutes of high-temperature steam sterilization, and t...

Embodiment 2

[0044] Example 2: see figure 1 , the method for preparing ganoderma lucidum mycelia liquid with the slag water that produces potato starch as medium, its steps are: its preparation step is the same as embodiment 1.

[0045] 1. Production and transplantation of test tube agar slant medium:

[0046] ①Preparation of culture medium: Add 2.2g of glucose and 2.2g of agar to 120ml of slag water produced by potato starch production, with a natural pH value. Under the condition of bacteria, it was divided into 15×1.5cm dry and sterilized test tubes, placed on a slope, and set aside after solidification; preparation of sawdust agar slant medium: add 5g of sawdust, glucose 2g, agar 2g and the rest are the same as above.

[0047] ②Transplantation culture: Inoculate the ganoderma lucidum mycelium block in the slant surface of the test tube of the parent species on the slant medium of the test tube and culture it statically at 26°C for 5 days, then transfer it to the slant medium of sawdu...

Embodiment 3

[0053] Embodiment 3: the method for preparing Ganoderma lucidum mycelia fluid with the bad water produced in beer production as a medium, the steps are: the preparation steps are the same as in Example 1.

[0054] 1. Production and transplantation of test tube agar slant medium:

[0055] ①Preparation of culture medium: add 1.8g of glucose and 1.8g of agar to 80ml of bad water produced by beer production, and the pH value is natural. Under the condition of bacterium, put it in a dry and sterilized test tube of 15×1.5cm, place it on an inclined plane, and wait for it to solidify for later use; preparation of sawdust agar inclined medium: add 4g of sawdust and 1.8 of glucose to 80ml of bad water produced by beer production. g, agar 1.8g, and the rest are the same as above.

[0056] ②Transplantation culture: Inoculate the ganoderma lucidum mycelium block in the slant surface of the test tube of the parent species on the slant medium of the test tube and culture it statically at 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com