Method for catalyzing and dehydrating ethanol

A technology for catalytic dehydration and aqueous ethanol solution, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problem of low catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

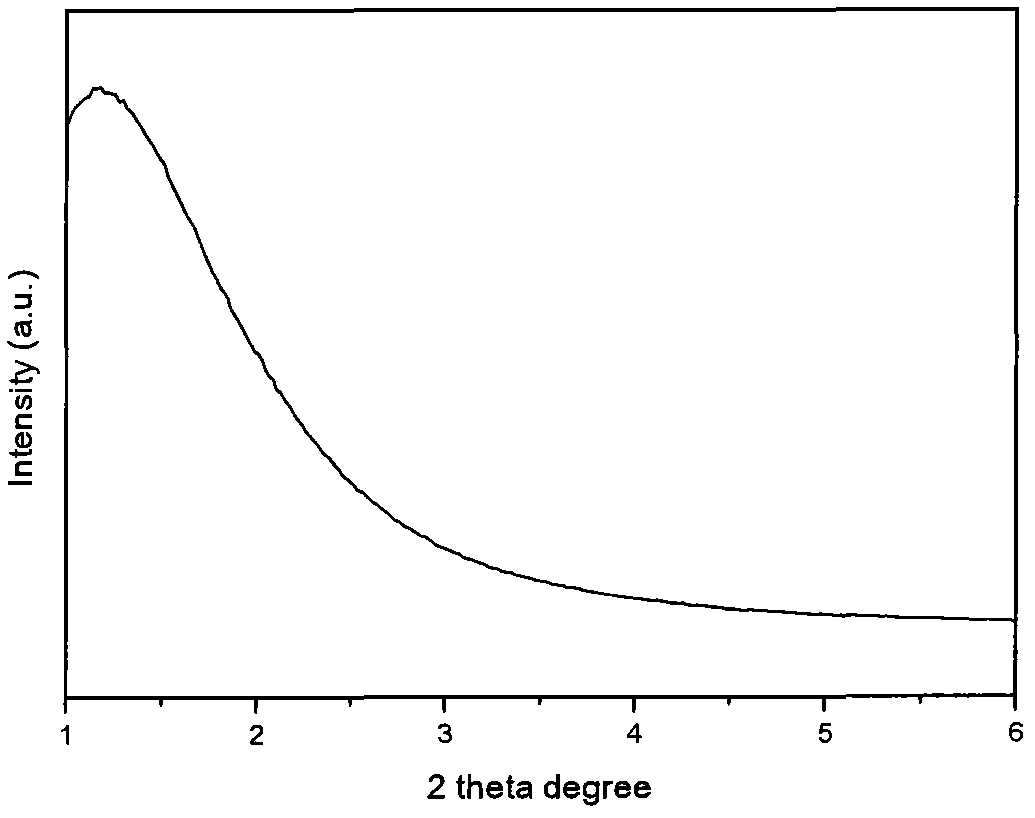

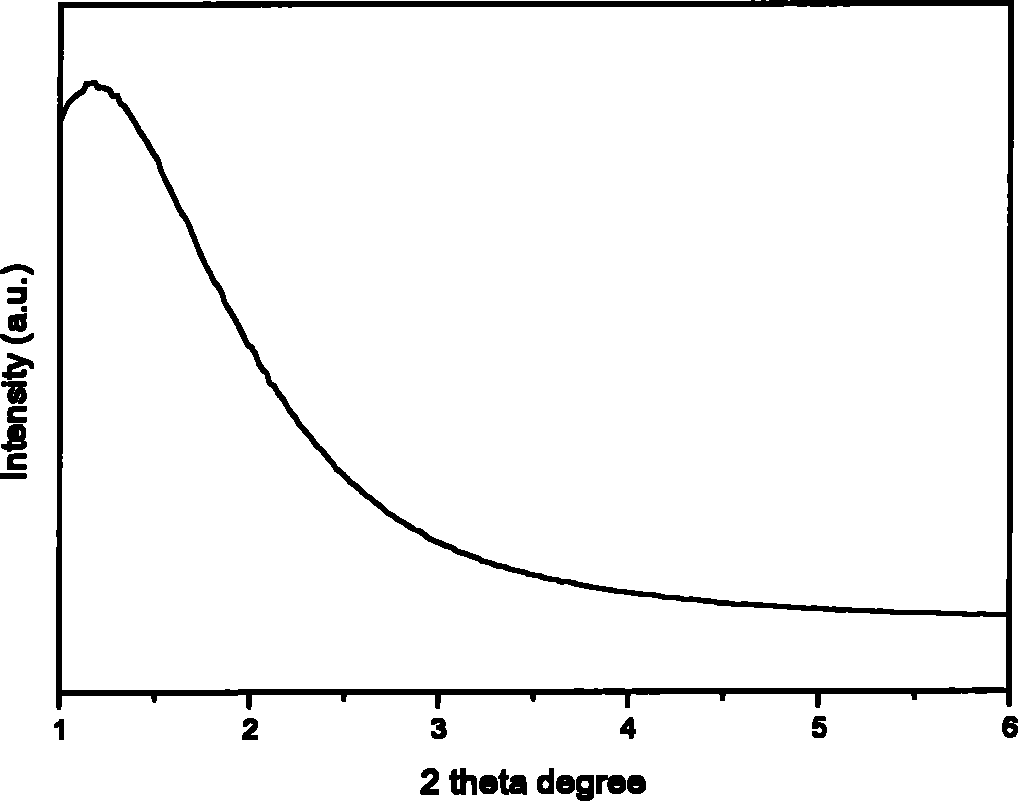

Image

Examples

Embodiment 1

[0016] Get 7.8 grams of Thomme stone powder (Al 2 o 3 mass content 70%) in 100 milliliters of water, reflux at 80°C for 0.5 hour, dropwise add 7 milliliters of 1 mol / liter nitric acid solution for degumming, and continue stirring for 10 hours to obtain stable, highly dispersed 1 mol / liter boehmite Sol.

[0017] At 35°C, 10.92 grams of cetyltrimethylammonium bromide (C 16 NBr), 180 milliliters of 2 moles / liter of ammonia water were added to 120 milliliters of 1 moles / liter of boehmite sol, and after being completely dissolved, the mixture was stirred overnight, hydrothermally treated at 100° C. for 1 day, filtered, washed, dried, and roasted at 600° C. for 5 hours. A finished catalyst is obtained.

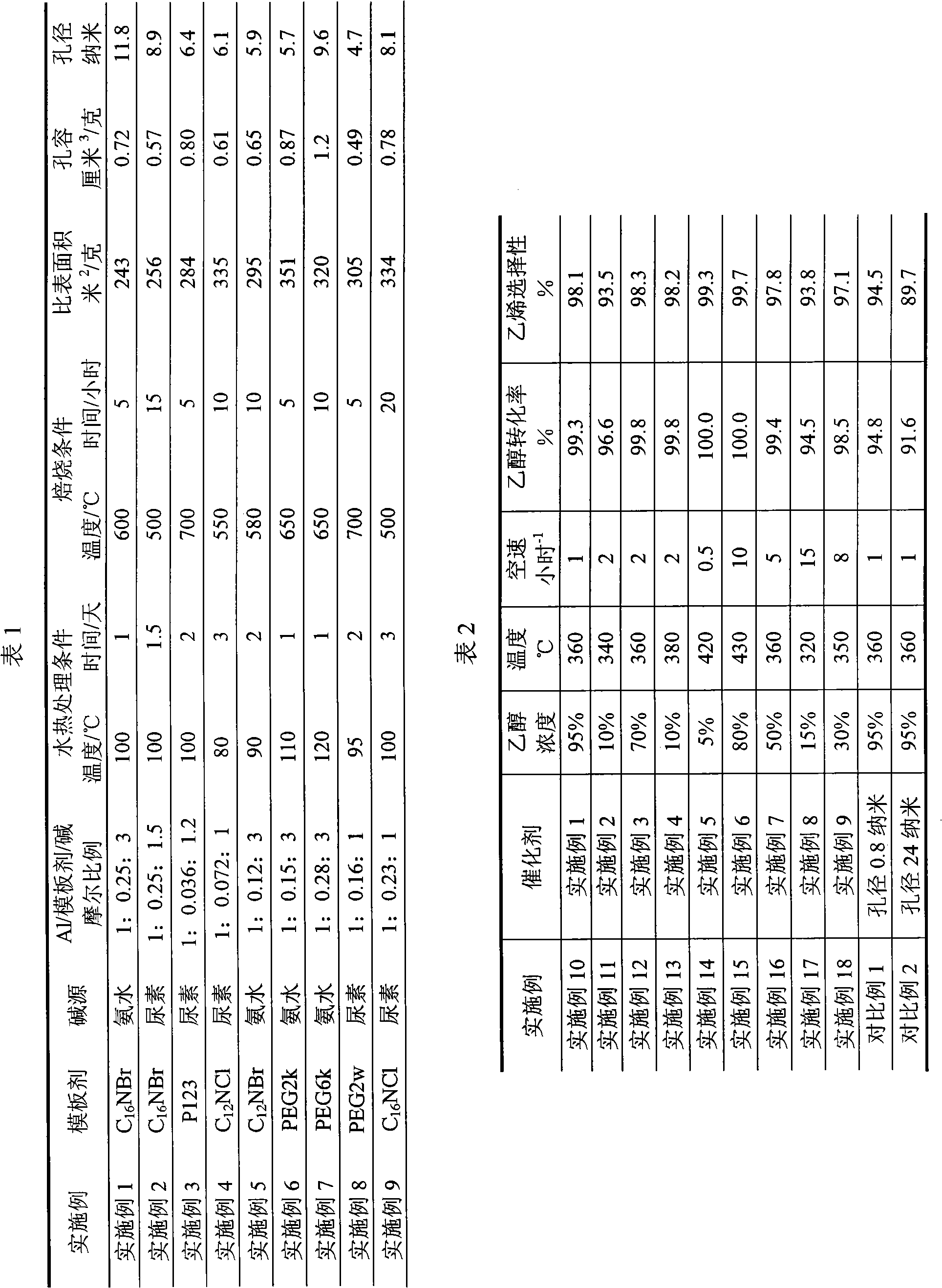

Embodiment 2~9

[0019] Others are cetyltrimethylammonium chloride (C 16 NCl), dodecyltrimethylammonium bromide (C 12 NBr), dodecyltrimethylammonium chloride (C 12 NCl)), polyethylene oxide-polypropylene oxide-polyethylene oxide (P123), polyethylene glycol 2000 (PEG2k), polyethylene glycol 6000 (PEG6k), polyethylene glycol 20000 (PEG2w) The preparation conditions of the template agent are according to the steps of [Example 1], and the specific material ratio and preparation conditions are shown in Table 1.

Embodiment 10

[0020] [Example 10] Catalytic Performance Evaluation

[0021] The performance evaluation of the catalyst was carried out on a fixed-bed reaction device at normal pressure, using a stainless steel reactor with an inner diameter of 10 mm, the catalyst was the catalyst prepared in [Example 1], the loading capacity was 10 ml, the reaction temperature was 360 ° C, and the normal pressure The following reaction, the raw material is 95% ethanol, and the space velocity is 1 hour -1 . The reaction products were analyzed separately after gas-liquid separation, and the reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com