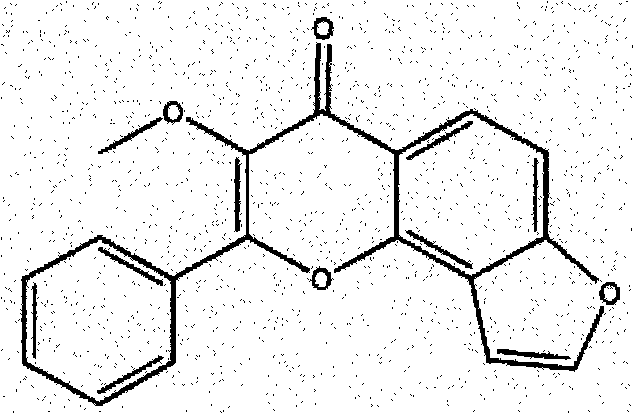

Method for purifying high-content karanjin

A technology of aquaxanthin and a purification method, which is applied in the field of natural medicinal phytochemistry and achieves the effects of strong feasibility, large adsorption capacity and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take dried flower bean stems and branches as raw materials, weigh 1kg after crushing and put it into the percolation cylinder, add 7 times of 80% ethanol percolation extraction for 3 times, each time for 4 hours, combine the extracts; concentrate the extracts to 1 / 4 of the original volume , ultrasonically extracted twice with an equal volume of petroleum ether, discarded the extract, put the raffinate on an AB-8 macroporous adsorption resin column (diameter-to-height ratio 1:5), eluted with water until colorless, and then used 6 times column volume 70% ethanol was eluted, collected, the reagent was recovered under reduced pressure, concentrated, and the obtained extract was subjected to polyamide column chromatography, followed by ethyl acetate, ethyl acetate-methanol (9:1), ethyl acetate- Gradient elution with methanol (9:4), collecting the eluate, recovering the reagent, concentrating to dryness to obtain coarse crystals, and recrystallizing repeatedly with 95% ethanol...

Embodiment 2

[0021] Take dried flower bean stems and branches as raw materials, weigh 3.5kg after crushing and put it into an extraction tank, add 10 times of 70% ethanol and heat and reflux for extraction twice, each time for 3 hours, and combine the extracts; concentrate the extracts to 1 / 1 of the original volume 5. Use an equal volume of petroleum ether to ultrasonically extract twice, discard the extract, put the raffinate on a D101 macroporous adsorption resin column (diameter-to-height ratio 1:10), elute with water until colorless, and then use 5 80% of the column volume was eluted with methanol, collected, the reagent was recovered under reduced pressure, concentrated, and the obtained extract was subjected to polyamide column chromatography, followed by ethyl acetate, ethyl acetate-methanol (9:1), ethyl acetate-methanol (9:4) gradient elution, collect the eluate, recover the reagent, concentrate to dryness to obtain coarse crystals, and repeat recrystallization with 95% ethanol for ...

Embodiment 3

[0023] Take dried flower bean stems and branches as raw materials, weigh 5kg after crushing and put it into the extraction tank, add 8 times of 60% ethanol to cold soak and extract twice, each time for 4 hours, combine the extracts; concentrate the extracts to 1 / 7 of the original volume , ultrasonically extracted twice with an equal volume of petroleum ether, discarded the extract, put the raffinate on a NKA-9 macroporous adsorption resin column (diameter-to-height ratio 1:15), first eluted with water until colorless, and then used 8 times the column volume was eluted with 75% acetone, collected, the reagent was recovered under reduced pressure, concentrated, and the obtained extract was subjected to polyamide column chromatography, followed by ethyl acetate, ethyl acetate-methanol (9:1), ethyl acetate- Gradient elution with methanol (9:4), collecting the eluate, recovering the reagent, concentrating to dryness to obtain coarse crystals, and recrystallizing repeatedly with 95% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com