Composition composed of metal and ceramic and its preparation method, cermet and Raymond mill

A technology of cermet and composition, applied in the field of cermet, can solve the problems of high cost, poor wear resistance and toughness of cermet, and achieve the effects of low cost, good toughness, high hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention provides a cermet. The preparation method of the cermet includes the following steps:

[0048] 1) Press mold the cermet composition to obtain a green body, and bake;

[0049] 2) The baked green body is subjected to isostatic pressure sintering under anaerobic conditions, the sintering pressure is 100-400 MPa, and the sintering temperature is 900-2000°C.

[0050] In the present invention, the cermet composition is a paste, and the paste is press-molded to obtain a green body, which is then transferred to an oven for baking. The baking temperature is 200-350℃, and the heating rate during baking is 10℃ / min.

[0051] Under anaerobic conditions, the baked green body is transferred to an isostatic press for isostatic sintering. Isostatic pressing sintering is well known to those skilled in the art, and includes putting the sample to be burned into the jacket of an isopressing machine, and performing hot isostatic pressing sintering according to a certain heatin...

Embodiment 1

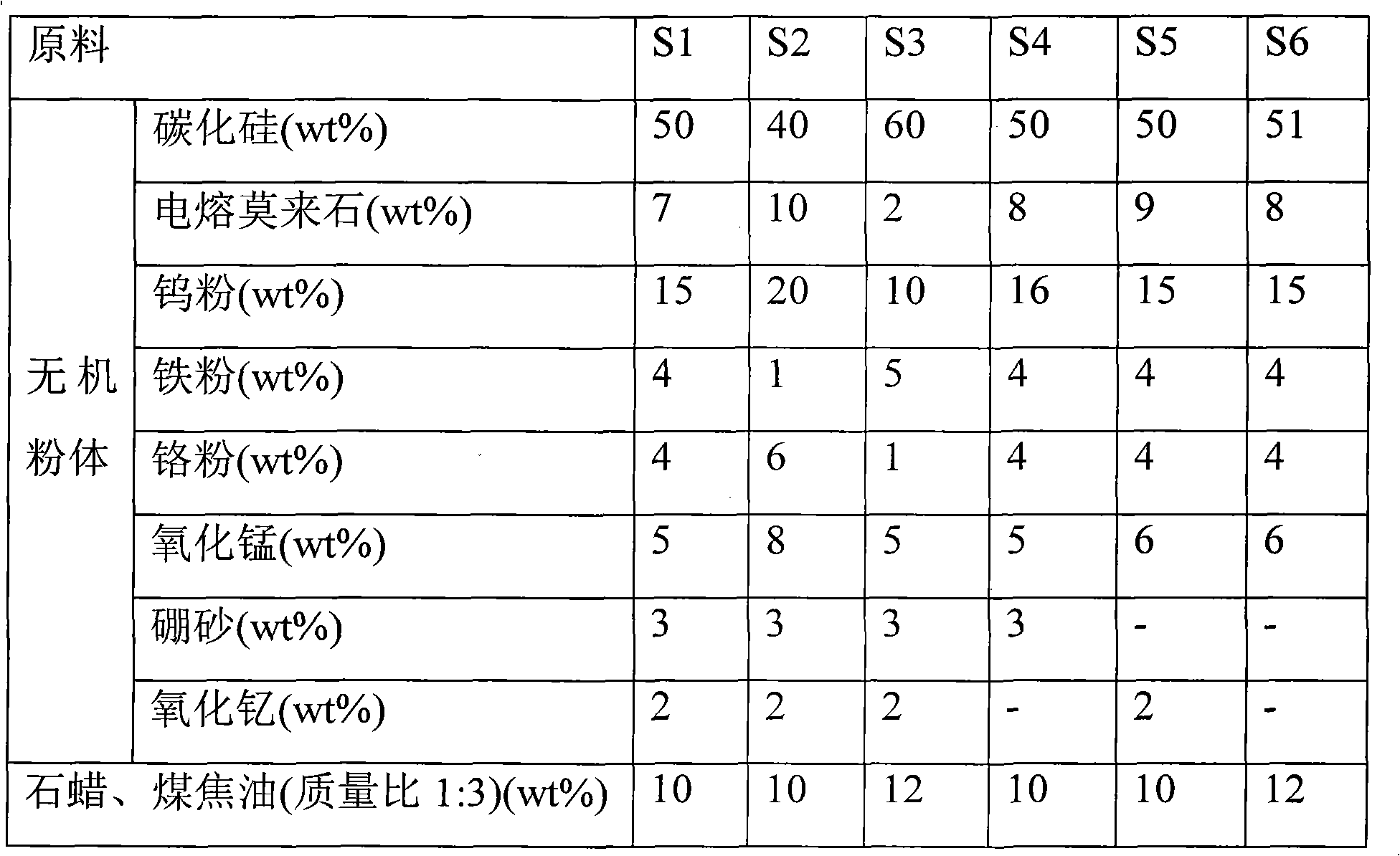

[0058] (1) Mix the inorganic powder material evenly according to the ratio shown in Table 1, and transfer it to a stirring ball mill for 2 hours. The particle size of the inorganic powder material is 0.5-2μm; then add paraffin wax and coal tar (the mass ratio is 1:3 ), mixed uniformly to prepare a paste to obtain the cermet composition S1 of this embodiment.

[0059] (2) The cermet composition S1 is press-molded into a green body, and then placed in an oven for baking. The temperature rise curve is: heating from room temperature to 300°C, and the heating rate is 10°C / min.

[0060] (3) Put the baked green body into the jacket of the isopressor, and perform hot isostatic pressing sintering under oxygen-free conditions; where the pressure transmission medium is nitrogen, the jacket material is glass, and the sintering pressure is 150MPa ; Sintering temperature conditions: the heating temperature is set to 950℃, and the holding time is 1h; then it is heated to 1700℃ and the holding tim...

Embodiment 2

[0062] The cermet composition and cermet of this embodiment were prepared by the same steps as in embodiment 1, except that:

[0063] In step (1), the ratio of each raw material is shown in Table 1;

[0064] In step (2), the heating curve is: heating from room temperature to 350°C, and the heating rate is 10°C / min;

[0065] In step (3), the sintering conditions include: the pressure transmission medium is helium, the jacket material is glass, and the sintering pressure is 250 MPa; the sintering temperature conditions: the heating temperature is set to 900 ℃, the holding time is 1.5 h; and then heating to 1850 ℃, keep for 4h.

[0066] Through the above steps, the cermet of this embodiment is obtained, denoted as S22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com