Hollow silicon dioxide microsphere with pores in graded distribution as well as preparation method and application thereof

A silica, gradient distribution technology, applied in the field of porous materials, to achieve the effect of optimizing performance, increasing adsorption speed, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

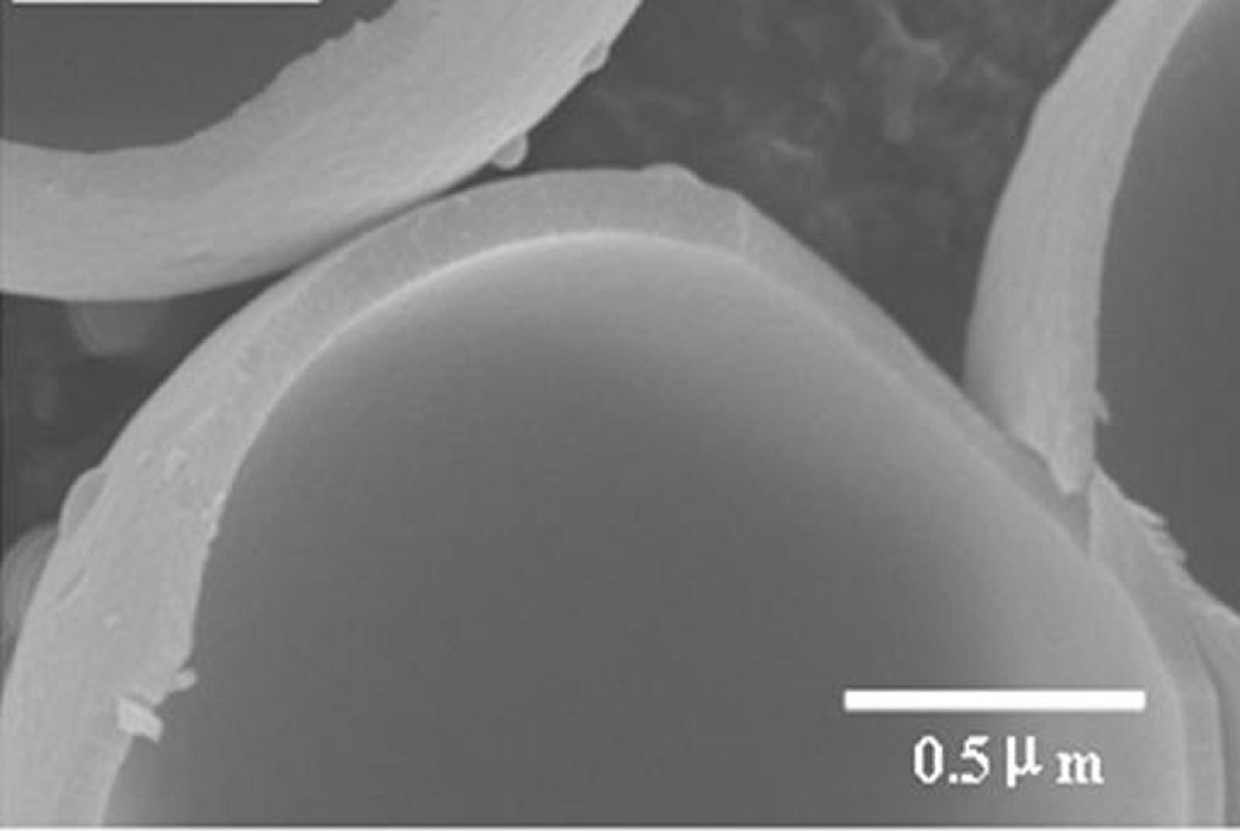

[0022] Prepare hollow silica microspheres coated with two layers of silica shells. The molar ratio of raw materials required for each layer of silica shells is: ethanol: water: pore former: TEOS: NH 3 ·H 2 O=58:144:0.3:1:10. The preparation method is as follows:

[0023] 1. Disperse PS microspheres in EtOH and H 2 In the mixed solution of O, after stirring for 30 minutes, add CTAB, after stirring for another 30 minutes, add TEOS and NH 3 ·H 2 O, continue to stir and react for 1 hour, then the reaction ends, filter with suction, wash with water, and obtain PS / CTAB-SiO 2 Composite microspheres, that is, composite microspheres coated with a layer of silica shell;

[0024] 2. The above PS / CTAB-SiO 2 The composite microspheres were dispersed in EtOH and H according to the same ratio 2 In the mixed solution of O, after stirring for 30 minutes, add TTAB, after stirring for another 30 minutes, add TEOS and NH 3 ·H 2 O, continue to stir and react for 1 hour, then the reaction ...

Embodiment 2

[0028] Prepare hollow silica microspheres coated with three layers of silica shells. The molar ratio of raw materials required for each layer of silica shells is: ethanol: water: pore former: TEOS: NH 3 ·H 2 O=58:144:0.3:1:10. The preparation method is as follows:

[0029] 1. Disperse PS microspheres in EtOH and H 2 In the mixed solution of O, after stirring for 30 minutes, add CTAB, after stirring for another 30 minutes, add TEOS and NH 3 ·H 2 O, continue to stir and react for 1 hour, then the reaction ends, filter with suction, wash with water, and obtain PS / CTAB-SiO 2 Composite microspheres, that is, composite microspheres coated with a layer of silica shell;

[0030] 2. Follow the same method and ratio as step 1 in PS / CTAB-SiO 2 A layer of silica shell is coated on the composite microspheres. The difference is that the pore-forming agent used is TTAB, and finally PS / CTAB-SiO 2 / TTAB-SiO 2 Composite microspheres;

[0031] 3. Mix PS / CTAB-SiO with the same ratio as s...

Embodiment 3

[0035] Preparation of coated two-layer SiO 2 shell hollow SiO 2 The microspheres, method and proportioning are the same as in Example 1, except that the second layer uses DTAB as a pore-forming agent.

[0036] The resulting hollow SiO 2 The thickness of the microsphere shell is 91nm, and the specific surface area of the sample is 654m 2 / g, the pore volume is 0.3888ml / g, the outer pore diameter is 1.72nm, and the inner pore diameter is 2.19nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com