Preparation method of catalyst for synthesizing diphenyl carbonate through transesterification

A technology of diphenyl carbonate and catalyst, which is applied in the field of preparation of catalyst for transesterification synthesis of diphenyl carbonate, can solve the problems of difficult separation, easy deactivation, difficult recycling, etc., and achieves increased dispersity, high activity and selectivity The effect of improving the adsorption speed and penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

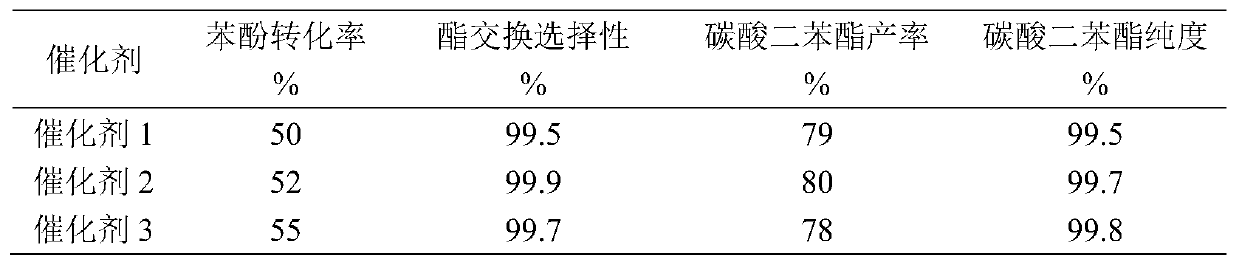

Embodiment 1

[0024] Using nitric acid with a mass concentration of 5wt%, fully mix 5% zinc oxide, 10% silicon dioxide and 85% alumina by mass fraction, extrude into a rod, with a diameter of about 1 mm, dry at 20°C for 2 hours, and dry at 50°C for 6 hours , calcined at 500°C for 5h, and cut into about 1cm to obtain Catalyst 1.

[0025] Phenol and dimethyl carbonate carry out pressurized reaction under the above-mentioned catalyst, transesterification obtains methyl phenyl carbonate, the molar ratio of dimethyl carbonate and phenol is 1, and catalyst dosage is 0.1wt%, pressure 0.5MPa, reaction time 5h. The reaction is carried out in a rectification tower with a bottom temperature of 180°C, a tower top temperature of 65°C, and a reflux ratio of 5.

[0026] The methyl phenyl carbonate obtained above was subjected to a decompression reaction under the above catalyst conditions, the catalyst dosage was 0.5wt%, the pressure was 0.05MPa, the reaction temperature was 160°C, and the reaction time ...

Embodiment 2

[0028] Use nitric acid with a mass concentration of 5wt%, fully mix the mass fraction of 10% zinc oxide, 25% titanium dioxide and 65% alumina, extrude into a strip, with a diameter of about 5mm, dry at 35°C for 7h, and dry at 90°C for 4h, 450 ℃ calcination for 2 hours, and cut into about 1.5 cm to obtain catalyst 2.

[0029] Phenol and dimethyl carbonate are subjected to pressurized reaction under the above catalyst, transesterification to obtain methyl phenyl carbonate, the molar ratio of dimethyl carbonate to phenol is 3, the catalyst dosage is 1wt%, the pressure is 1.5MPa, and the reaction time is 3h . The reaction is carried out in a rectification tower with a bottom temperature of 200°C, a tower top temperature of 90°C, and a reflux ratio of 15.

[0030] The methyl phenyl carbonate obtained above was subjected to a decompression reaction under the above catalyst conditions, the catalyst dosage was 1.5wt%, the pressure was 0.7MPa, the reaction temperature was 180°C, and t...

Embodiment 3

[0032] Use nitric acid with a mass concentration of 20 wt%, fully mix the mass fraction of 20% zirconia, 45% titanium dioxide and 35% TS molecular sieve, extrude into a rod, with a diameter of about 8mm, dry at 30°C for 12h, and dry at 80°C for 5h, 400 It was calcined at ℃ for 10 hours, cut into about 0.5 cm, and catalyst 3 was obtained.

[0033] Phenol and dimethyl carbonate were subjected to pressurized reaction under the above-mentioned catalyst, transesterified to obtain methyl phenyl carbonate, the molar ratio of dimethyl carbonate to phenol was 5, the catalyst dosage was 5 wt%, the pressure was 2 MPa, and the reaction time was 1 h. The reaction is carried out in a rectification tower, the temperature of the bottom of the tower is 230°C, the temperature of the top of the tower is 50°C, and the reflux ratio is 8.

[0034] The methyl phenyl carbonate obtained above was subjected to a decompression reaction under the above catalyst conditions, the catalyst dosage was 2.0wt%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com