Preparation method of tilmicosin

A technology of tilmicosin and tylosin phosphate, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of large yield loss of tilmicosin, difficulty in industrial production, and application problems. The scope is limited and other problems, and the production process is easy to control, the production safety is high, and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

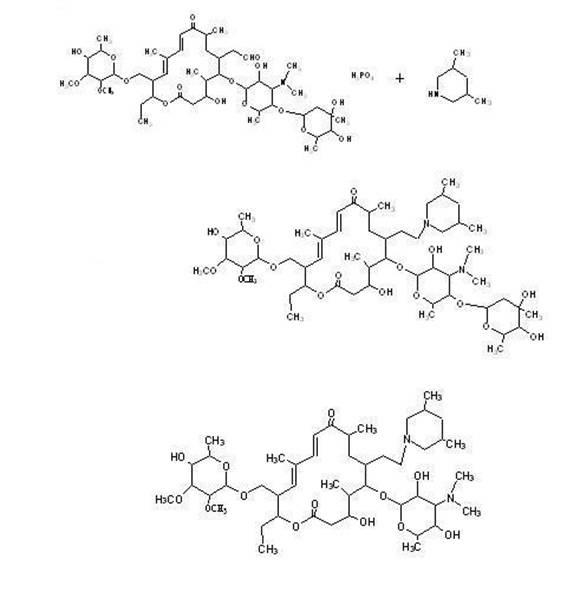

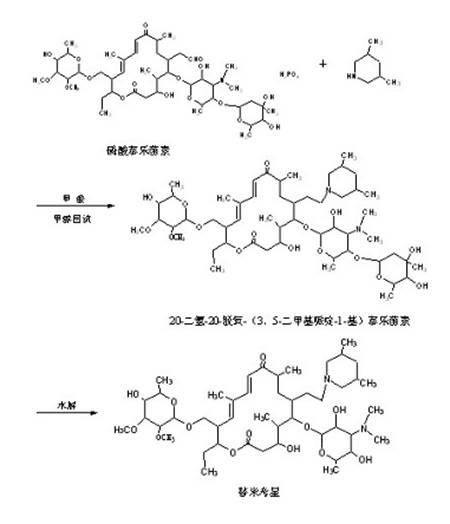

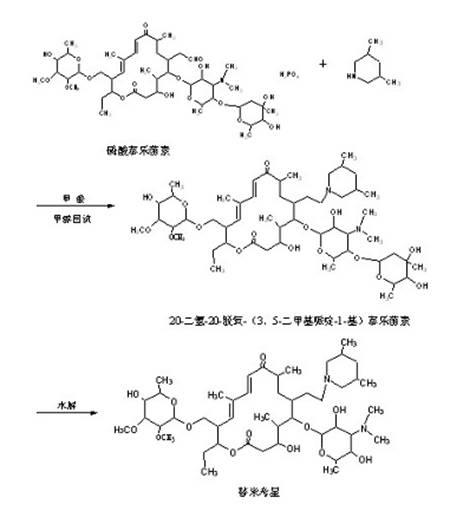

[0013] A kind of preparation method of tilmicosin according to the present invention, take tylosin phosphate as raw material, alcohol as solvent, anhydrous formic acid as catalyst and 3,5-dimethylpiperidine at 65-97°C After the reaction is complete, the intermediate 20-dihydro-20-deoxy-(3,5-dimethylpiperidin-1-yl) tylosin is obtained, the solvent is concentrated, and the residue is hydrolyzed by adding 0.1N sulfuric acid solution to obtain substituted Micoxin, the mass volume ratio of tylosin phosphate to alcohol is 1:2-10, the mass ratio of tylosin phosphate to 3,5-dimethylpiperidine to anhydrous formic acid is 1:0.11-0.17 :5.6-8, the mass volume ratio of tylosin phosphate to 0.1N sulfuric acid solution is 1:2-6, the reaction formula is as follows:

[0014]

[0015] The preparation method of tilmicosin of the present invention can have the following various embodiments.

Embodiment 1

[0017] The specific steps of the preparation method of tilmicosin of the present invention are as follows:

[0018] ①Take 100kg of tylosin phosphate, put it into a reaction kettle, add 600L of methanol, heat up to reflux, stir and dissolve, and obtain a solution;

[0019] ② Take 8 kg of anhydrous formic acid and add 50 L of methanol to dissolve, and obtain a mixed solution for later use;

[0020] 3. Add 17kg of 3,5-dimethylpiperidine to the dissolving solution of step 1., then dropwise add the mixed solution of step 2., react at methanol reflux temperature for 4-5 hours until complete, and concentrate methanol in vacuo to obtain intermediate 20 -Dihydro-20-deoxy-(3,5-dimethylpiperidin-1-yl)tylosin liquid;

[0021] ④Add 400L of 0.1N sulfuric acid solution to the liquid intermediate 20-dihydro-20-deoxy-(3,5-dimethylpiperidin-1-yl)tylosin, and react at 50°C for 1 hour, Then 50 L of 2N sodium hydroxide was added dropwise to adjust the base to separate out tilmicosin. After filtr...

Embodiment 2

[0023] The specific steps of the preparation method of tilmicosin of the present invention are:

[0024] ①Take 100kg of tylosin phosphate, put it into a reaction kettle, add 200L of methanol, heat up to reflux, stir and dissolve, and obtain a solution;

[0025] ② Take 6.8kg of anhydrous formic acid and add 50L of methanol to dissolve, and obtain a mixed solution after dissolution;

[0026] 3. Add 14kg of 3,5-dimethylpiperidine to the dissolving solution of step 1., then dropwise add the mixed solution of step 2., react at methanol reflux temperature for 5-5.5 hours until complete, and concentrate methanol in vacuo to obtain intermediate 20 -Dihydro-20-deoxy-(3,5-dimethylpiperidin-1-yl)tylosin liquid;

[0027] ④Add 400L of 0.1N sulfuric acid solution to the liquid intermediate 20-dihydro-20-deoxy-(3,5-dimethylpiperidin-1-yl)tylosin, and react at 50°C for 1 hour, Then 50 L of 2N sodium hydroxide was added dropwise to adjust the base to separate out tilmicosin. After filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com