Swelling copolymerization preparation method of N-vinyl pyrrolidone and divinylbenzene monodisperse microsphere

A technology of vinylpyrrolidone and divinylbenzene, which is applied in the field of polymer chemistry and can solve problems such as application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 10.8g of polyvinylpyrrolidone and 600ml of absolute ethanol into a 1000ml four-neck flask, stir until the polyvinylpyrrolidone is completely dissolved, raise the temperature to 70°C under the protection of nitrogen, and then add 150g of styrene dissolved in 3.8g of azobisisobutyronitrile solution for 24 hours. Filter, wash with absolute ethanol, dry to constant weight, and set aside.

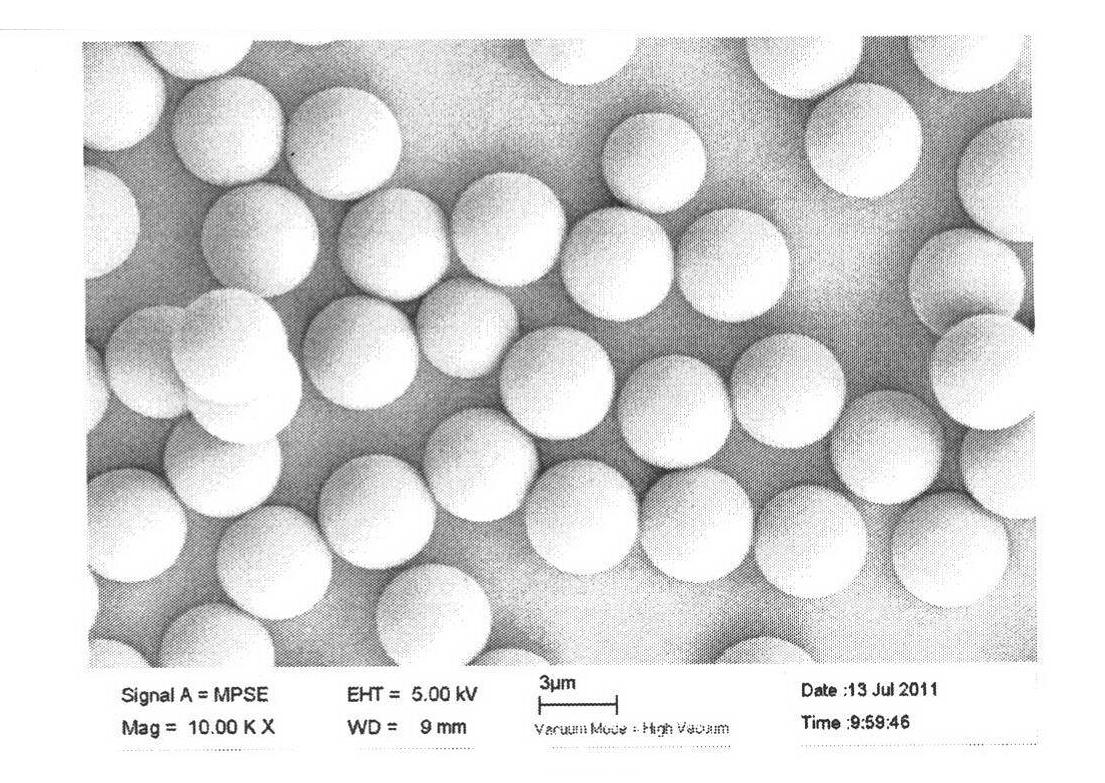

[0029] Gained polystyrene microspheres have good monodispersity, and the particle diameter is 5.0um, and its scanning electron microscope photo is as follows: figure 1 shown.

Embodiment 2

[0031] In a 1000ml four-neck flask, add 40g of the monodisperse microspheres prepared in Example 1 into 250ml of water containing 0.3g of hydroxypropylmethylcellulose, stir and heat to 40°C, and stir at 40°C for 3 hours.

[0032] After mixing 60g of divinylbenzene, 50g of N-vinylpyrrolidone, 80g of toluene and 1.2g of azobisisobutyronitrile, add 200ml of water containing 0.1g of hydroxypropyl methylcellulose and 1g of TritonX-405, mix and emulsify in It was slowly added dropwise into the solution at 40° C. for a total of 5 hours, and then the swelling was continued for 8 hours, and then 100 g of 1% hydroxypropylmethylcellulose aqueous solution was added. Heating to 88°C, the polymerization reaction was carried out for 12 hours.

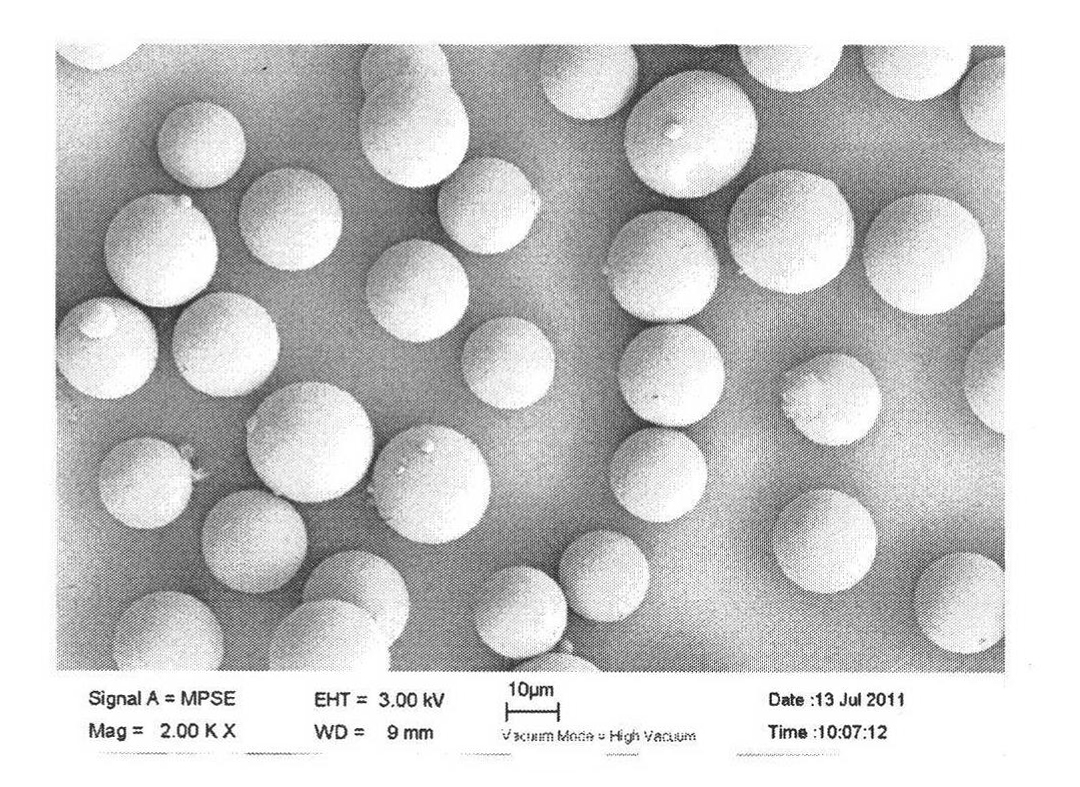

[0033] Finally, conventional methods such as filtration, lotion, re-filtration, drying, and pore extraction agent are used to recover the copolymerized microspheres. The particle size of the obtained copolymerized microspheres is concentrated between...

Embodiment 3

[0035] In a 1000ml four-neck flask, add 40g of the monodisperse microspheres prepared in Example 1 into 200ml of water containing 0.3g of hydroxypropylmethylcellulose, stir and heat to 40°C, and stir at 40°C for 3 hours.

[0036] After mixing 60g of divinylbenzene, 50g of N-vinylpyrrolidone, 80g of toluene and 1.2g of azobisisobutyronitrile, add 200ml of water containing 0.1g of hydroxypropyl methylcellulose and 1g of TritonX-405, mix and emulsify in It was slowly added dropwise into the solution at 40° C. for a total of 5 hours, and then the swelling was continued for 8 hours, and then 100 g of 1% hydroxypropylmethylcellulose aqueous solution was added. Heating to 88°C, the polymerization reaction was carried out for 2 hours.

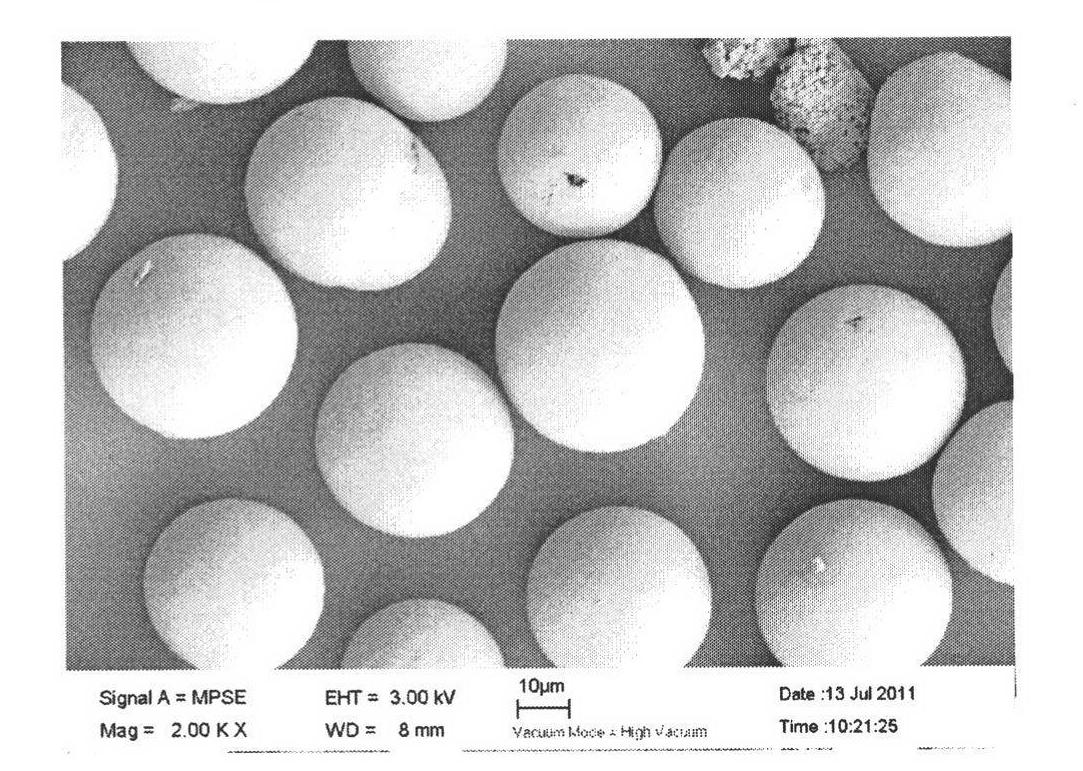

[0037] Lower the temperature and prepare emulsion 2 at the same time. After mixing 30g of divinylbenzene, 30g of N-vinylpyrrolidone, 40g of toluene, 20g of n-heptane and 0.8g of azobisisobutyronitrile, add 0.1g of hydroxypropylmethylcellulose Mix and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com