Preparation method for magnolol molecularly imprinted polymer film

A technology of molecular imprinting and polymer membranes, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of high preparation process requirements, large amount of raw materials, and low imprinting efficiency. Achieve the effect of good separation effect, high reuse rate, and reduce preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

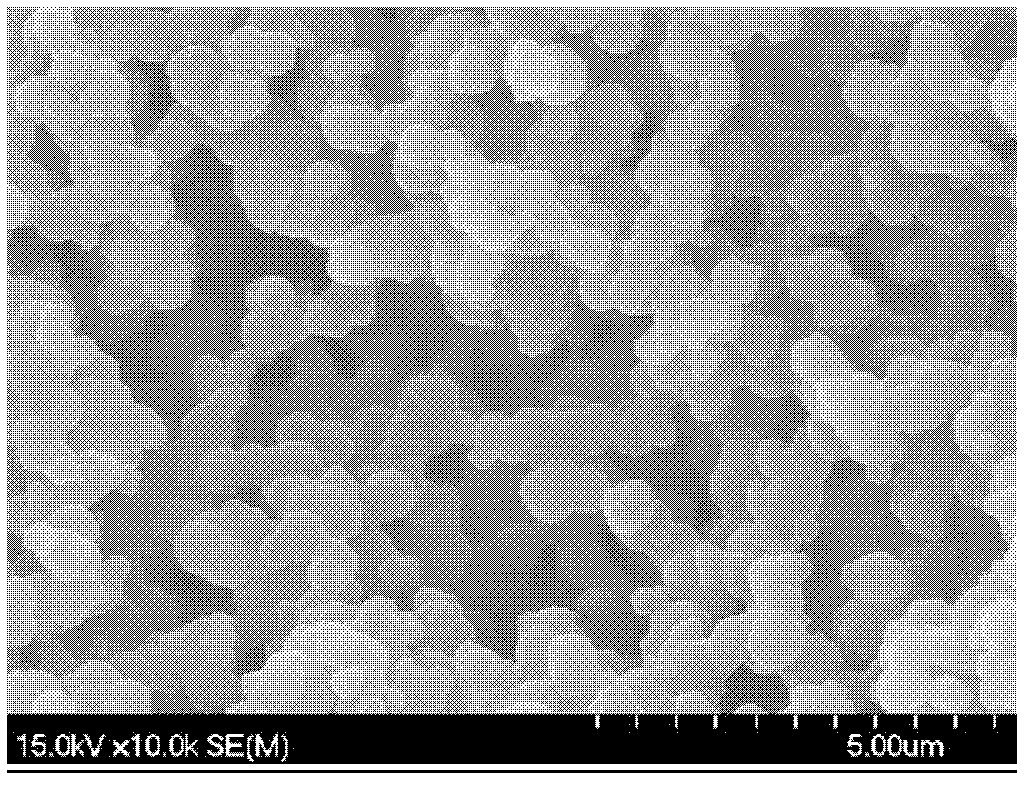

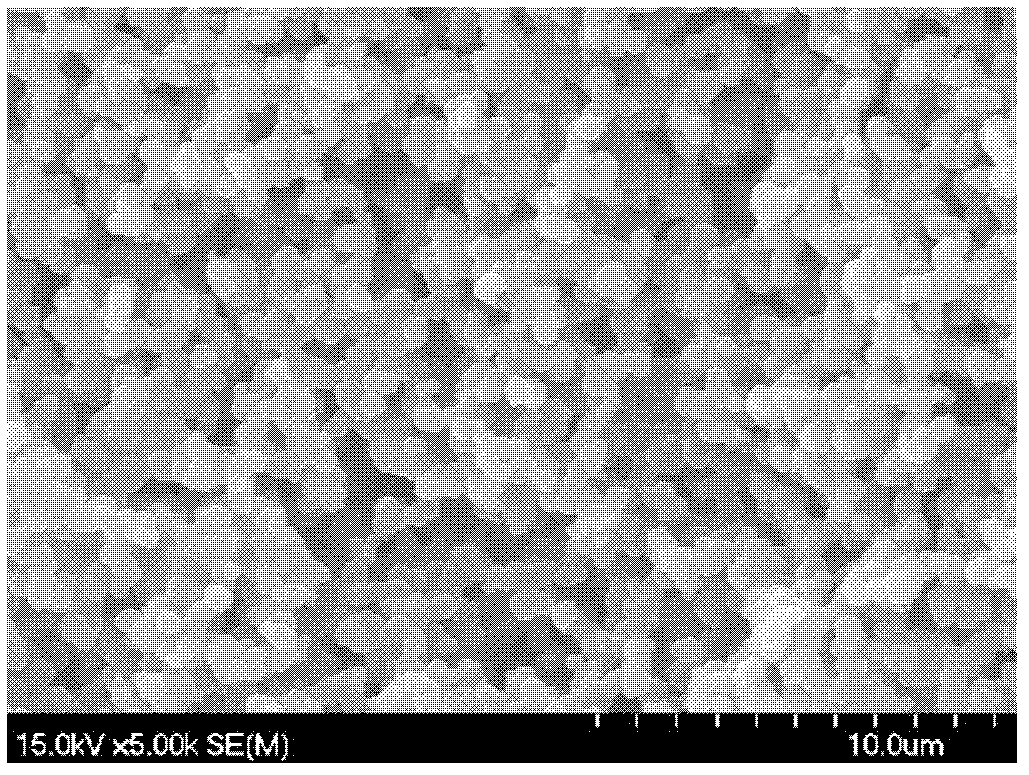

[0053] Put 0.20mmol of magnolol and 0.60mmol of HP-β-CD into a ball mill and mill for 60min to obtain the imprinted molecular clathrate, and mix it with 0.20mmol of methacrylamide, 0.80mmol of acrylic acid, and 5.00mmol of ethyl Diol dimethacrylate and 0.15 mmol of azobisisobutyronitrile were dissolved in 4.50 ml of tetrahydrofuran and 0.50 ml of dimethyl sulfoxide, ultrasonically degassed for 30.00 min, added 0.90 g of cellulose acetate, ultrasonically and Stir continuously for 4.00h to obtain a mixed solution. Soak a filter paper of a certain size in the mixture for about 6.00 minutes, take out the filter paper, sandwich it between two glass slides, place it in an oven and heat it for 3.00 hours of polymerization at a polymerization temperature of 60.00°C to obtain a polymer. The polymer was sonicated for 4.00 h with 40 ml of a mixed solution of methanol and acetic acid at a volume ratio of 9.00:1.00 to remove imprinted molecules, and then the acetic acid molecules were wash...

Embodiment 2

[0055] Put 0.20mmol of magnolol and 0.10mmol of β-CD into a ball mill and mill for 90 minutes to obtain the imprinted molecular clathrate, and mix it with 0.80mmol of methacrylamide and 3.00mmol of trimethoxypropane trimethyl Acrylate and 0.15 mmol of benzoyl peroxide were dissolved in 4.00 ml of tetrahydrofuran and 0.50 ml of dimethyl sulfoxide, ultrasonically degassed for 20.00 min, 0.50 g of cellulose acetate was added, and ultrasonically stirred continuously for 3.00 h to obtain Mixture. Soak a filter paper of a certain size in the mixture for about 6.00 minutes, take out the filter paper, sandwich it between two glass slides, place it in an oven and heat it for 4.00 hours of polymerization at a polymerization temperature of 50.00°C to obtain a polymer. The polymer was sonicated for 4.50 h with 40 ml of methanol and acetic acid mixed solution with a volume ratio of 8.00:1.00 to remove imprinted molecules, and then methanol was used to wash away acetic acid molecules. Fina...

Embodiment 3

[0057] Put 0.80mmol of magnolol and 0.80mmol of M-β-CD into a ball mill and mill for 40 minutes to obtain the imprinted molecular clathrate, and mix it with 0.90mmol of methacrylamide, 0.40mmol of acrylic acid, and 4.50mmol of pentaerythritol Dissolve triacrylate and 0.21 mmol of azobisisobutyronitrile in 5.00 ml of tetrahydrofuran and 0.50 ml of dimethyl sulfoxide, ultrasonically degas for 25.00 min, add 0.80 g of cellulose acetate, ultrasonically and continuously stir for 4.50 h , to obtain a mixture. Soak a filter paper of a certain size in the mixed solution for about 4.00min, take out the filter paper, clamp it between two glass slides, put it in an oven and heat it for polymerization for 3.50h at a polymerization temperature of 55.00°C to obtain a polymer. The polymer was sonicated for 8.00 h with 40 ml of a mixed solution of methanol and acetic acid at a volume ratio of 5.00:1.00 to remove imprinted molecules, and then the acetic acid molecules were washed away with met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com