Preparation method of cadmium ion surface imprint adsorbing material

A technology of surface imprinting and adsorption materials, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. Diffusion resistance is large, and it is difficult to identify site binding, etc., to achieve high elution efficiency, high mechanical strength, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

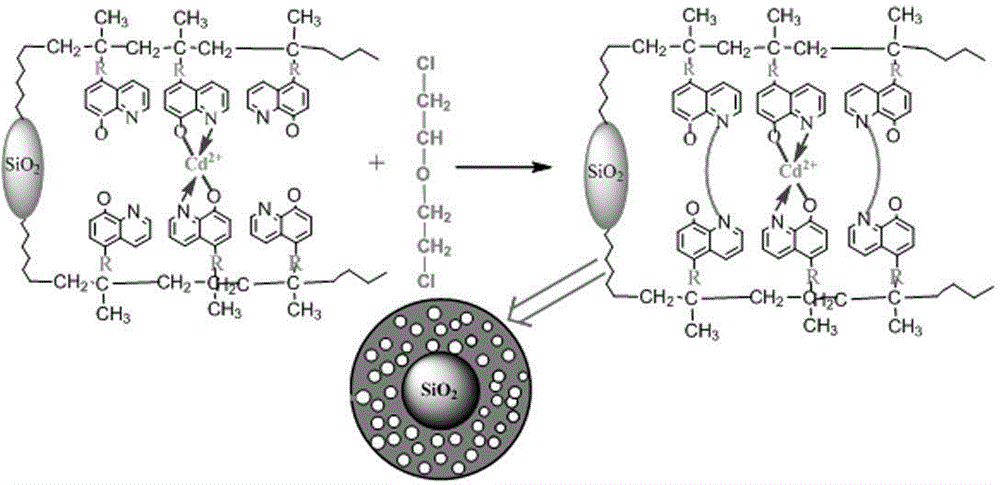

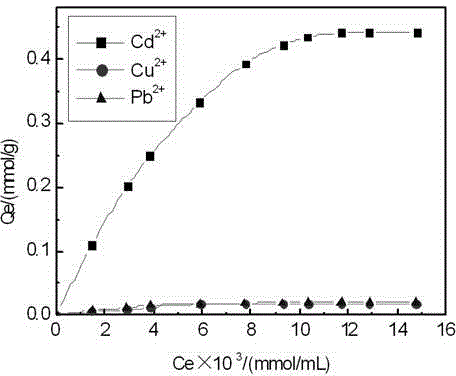

example 1

[0016] Example 1: Put 0.1 g of functional grafted particles HQ-PHEMA / SiO2 (the degree of grafting of PHEMA is 40 g / 100 g, the bonding density of HQ is 1.85 mmol / g) in 500 mL of 0.01 mol / L Cd 2+ In the ionic water solution, adjust the pH value of the solution system with dilute sodium hydroxide solution to make pH = 5.5, place the mixed solution in a constant temperature oscillator, and shake at a constant temperature for 4 h to make the functional grafted particles HQ-PHEMA / SiO 2 to Cd 2+ The adsorption of ions reaches saturation, and the particles are filtered out and dried in vacuum. 0.5 g of saturated adsorbed Cd 2+ Ionically functional grafted microparticles placed in Cd-containing 2+ ions (0.01mol / L) in a mixed solvent of water and ethanol (the volume ratio of water and ethanol is 7:3), adjust the pH value of the system with dilute NaOH solution to make pH = 5.5, add 5 mL of dichloro Aqueous diethyl ether solution (1%) was stirred at 45°C for 24 h for the cross-linkin...

example 2

[0017] Example 2: 0.1 g of functional grafted particles HQ-PHEMA / SiO 2 ( The degree of grafting of PHEMA is 30 g / 100 g, and the bonding density of HQ is 1.75 mmol / g) placed in 500 mL of Cd with a concentration of 0.01 mol / L 2+ In the ionic water solution, adjust the pH value of the solution system with dilute sodium hydroxide solution to make pH = 5.5, place the mixed solution in a constant temperature oscillator, and shake at a constant temperature for 4 h to make the functional grafted particles HQ-PHEMA / SiO 2 to Cd 2+ The adsorption of ions reaches saturation, and the particles are filtered out and dried in vacuum. 0.5 g of saturated adsorbed Cd 2+ Ionically functional grafted microparticles placed in Cd-containing 2+ ions (concentration of 0.01mol / L) in a mixed solvent of water and ethanol (volume ratio of water and ethanol is 7:3), use dilute NaOH solution to adjust the pH value of the system to pH = 5, add 4 mL of dichloro Aqueous diethyl ether solution (1%) was sti...

example 3

[0018] Example 3: 0.1 g of functional grafted particles HQ-PHEMA / SiO 2 ( The degree of grafting of PHEMA is 35 g / 100 g, and the bonding density of HQ is 1.8 mmol / g) placed in 500 mL of Cd with a concentration of 0.01 mol / L 2+ In the ionic water solution, adjust the pH value of the solution system with dilute sodium hydroxide solution to make pH = 5.5, place the mixed solution in a constant temperature oscillator, and shake at a constant temperature for 4 h to make the functional grafted particles HQ-PHEMA / SiO 2 to Cd 2+ The adsorption of ions reaches saturation, and the particles are filtered out and dried in vacuum. 0.5 g of saturated adsorbed Cd 2+ Ionic functional particles placed in the Cd-containing 2+ ions (concentration of 0.01mol / L) in a mixed solvent of water and ethanol (the volume of water and ethanol is 7:3), adjust the pH value of the system with dilute NaOH solution to make pH = 4.5, add 6 mL of dichloro Aqueous diethyl ether solution (1%) was stirred at 50°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com