Method for preparation of lead ion imprinted polymer microspheres by use of bi-functional monomer synergistic effect

An imprinted polymer, bifunctional monomer technology, applied in the fields of materials science and engineering and environmental science, can solve the problems of single monomer and poor selectivity, and achieve the effects of simple operation, fast adsorption rate and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

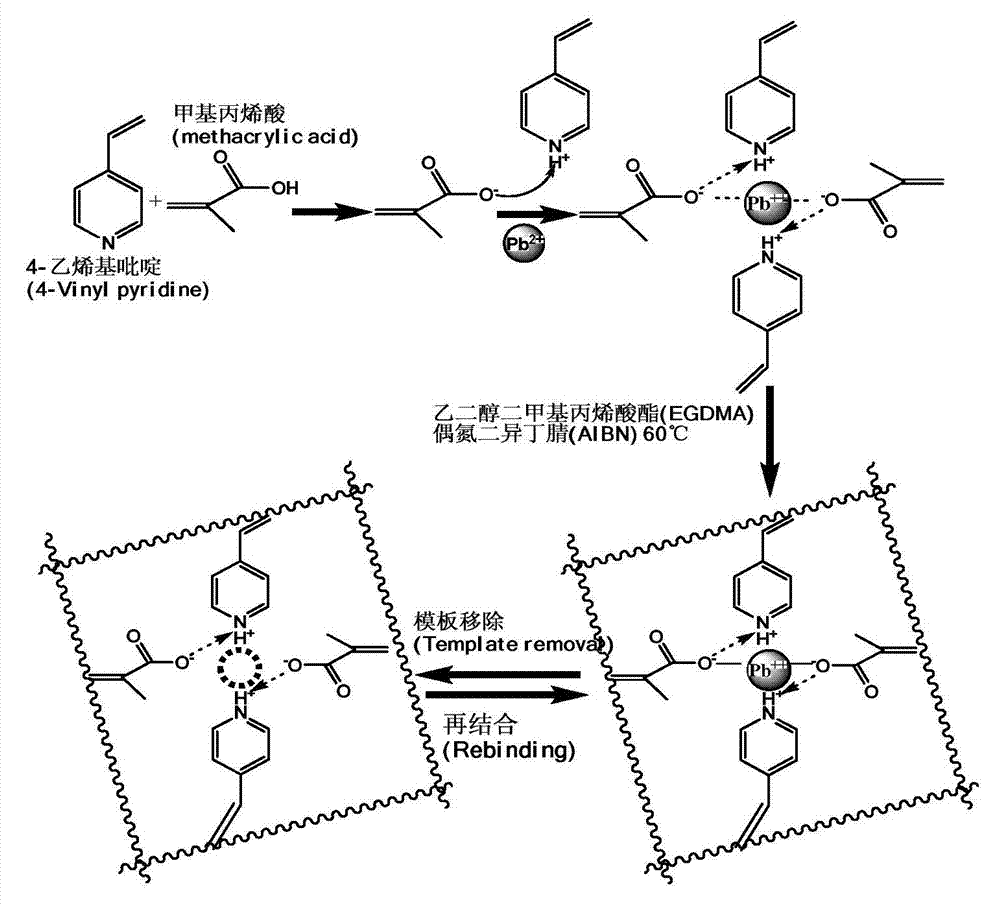

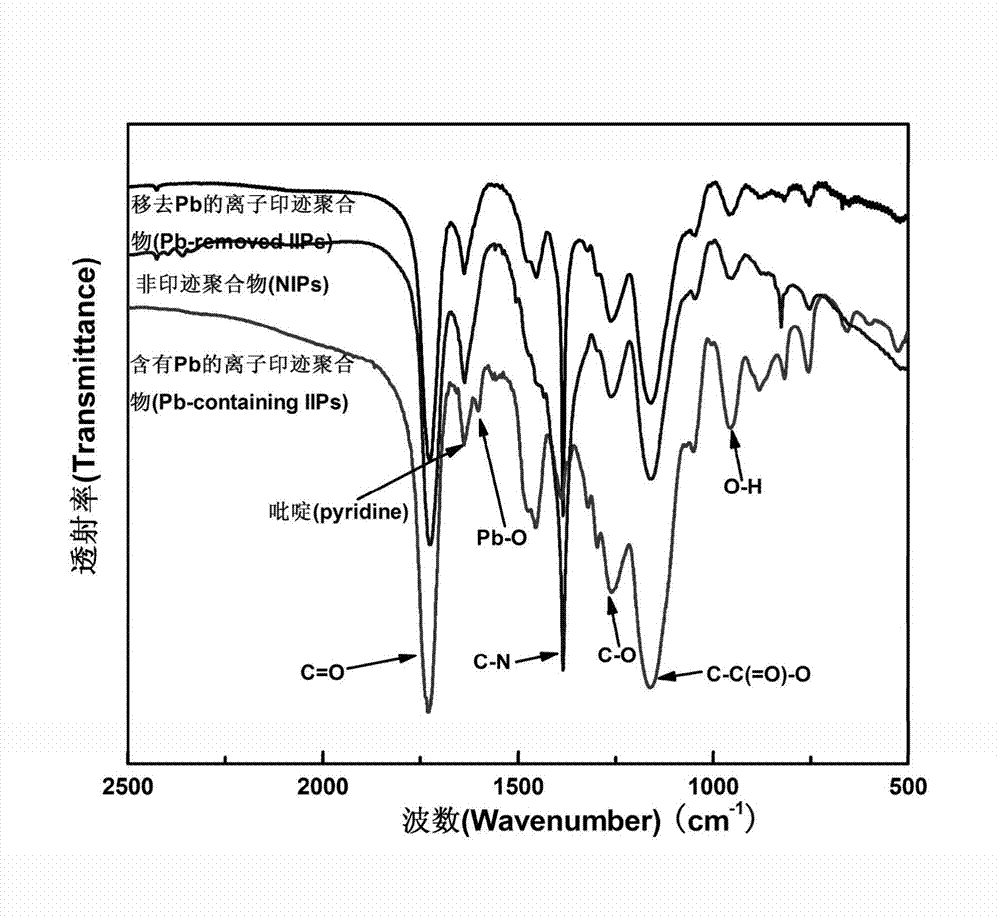

[0026] Dissolve the template ion lead ion and the functional monomer in a molar ratio of 1:4, that is, 2.5mmol and 10mmol, into a mixed solution of 30mL of hydroxyethylcellulose (1wt.%) aqueous solution and 15mL of toluene, and mix the solution Stir at a constant speed for 3 h at room temperature, and then add a crosslinking agent and an initiator. The functional monomers are methacrylic acid (5mmol) and tetravinylpyridine (5mmol), the crosslinking agent is ethylene glycol dimethacrylate (20mmol), and the initiator is azobisisobutyronitrile (40mg). After the mixture was sealed, it was ultrasonically treated with nitrogen in an ice bath, and then polymerized by heating and stirring to form a white powdery polymer. The mixture was first reacted in a water bath at 50°C for 6 hours, and then reacted at 60°C for 8 hours. Wash the synthesized white powdery polymer with a mixed solution of acetone and water at a volume ratio of 1:1 to remove surfactants and crosslinking agents, and t...

Embodiment 2

[0031] According to the operating procedures for preparing S-IIPs in Example 1, only a single functional monomer was used to prepare the lead ion imprinted polymer, wherein the functional monomers were respectively 10 mmol of methacrylic acid or 10 mmol of tetravinylpyridine, that is, to obtain Suspension-polymerized lead ion-imprinted polymer with acrylic acid as functional monomer or suspension-polymerized lead ion-imprinted polymer with tetravinylpyridine as functional monomer.

[0032] Take 20 mg of the bifunctional monomer suspension polymerization IIPs prepared in the above-mentioned Example 1 and the corresponding NIPs and bifunctional monomer bulk polymerization IIPs, suspension polymerization IIPs with methacrylic acid as the functional monomer, and tetravinylpyridine as the functional monomer. Suspension polymerized IIPs (compared to the polymer of the present invention and the above two single functions? Answer: Yes), dispersed in 5mL of different concentrations (0, ...

Embodiment 3

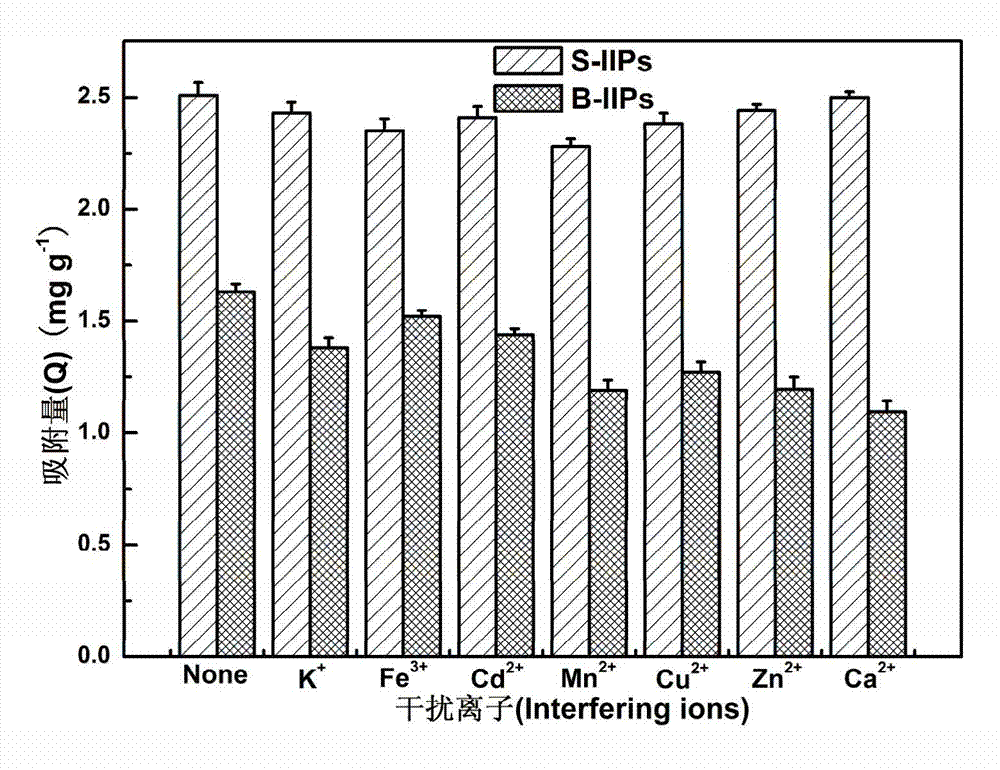

[0034] Take 20 mg of bifunctional monomer suspension polymerized imprinted polymers (S-IIPs) and bifunctional monomer bulk polymerized imprinted polymers (B-IIPs) and disperse them in 5 mL of lead ion solution with a concentration of 60 ppm, and the pH of the lead ion solution 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 6.5 and 7.0 respectively. Then the mixture was centrifuged at 7000r / min. Get the supernatant and measure the concentration of remaining lead ions with an atomic absorption spectrometer. According to the formula Q=(C 0 -C) m / V to obtain the adsorption capacity Q, so as to obtain the influence curve of pH on the adsorption performance of the imprinted polymer. It was found that S-IIPs and B-IIPs had the same trend, but the adsorption capacity of S-IIPs was higher than that of B-IIPs; in the acidic range, the adsorption capacity gradually increased with the increase of pH, and when the pH reached neutral, The adsorption capacity reaches a maximum. Finally, the solution with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com