Method for preparing oil gas absorbing composite material

A composite material, oil and gas technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

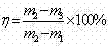

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 5kg of rice husk, wash, dry, crush, immerse in a hydrochloric acid solution with a mass fraction of 3%, stir at room temperature for 5 hours, filter out the rice husk, wash with deionized water until neutral, and dry to obtain impurity-removed rice shell powder;

[0022] (2) Weigh 2 kg of impurity-removed rice husk powder, add 20 kg of NaOH solution with a molar concentration of 2 mol / L, place it in a high-pressure reactor, heat up to 200 ° C, and filter after 24 hours of heat preservation; the filtrate is set aside, and the filter residue is washed with deionized water To neutrality, desiliconized rice husk powder is obtained after drying;

[0023] (3) Weigh 0.2 kg of desiliconized rice husk powder, add 1 kg of H 3 PO 4 Solution, mixed evenly, impregnated for 48 hours; then placed in a nitrogen atmosphere, heated to 800 ° C, activated for 4 hours; cooled at room temperature, washed with deionized water until neutral, and dried to prepare rice husk activated...

Embodiment 2

[0027] (1) Weigh 8 kg of rice husk, wash, dry, crush, immerse in hydrochloric acid solution with a mass fraction of 8%, stir at room temperature for 2 hours, filter out the rice husk, wash with deionized water until neutral, and dry to obtain impurity-removed rice shell powder;

[0028] (2) Weigh 3kg of impurity-removed rice husk powder, add 10kg of NaOH solution with a molar concentration of 5mol / L, place it in a high-pressure reactor, heat up to 100°C, keep it warm for 12h, and filter; the filtrate is set aside, and the filter residue is washed with deionized water To neutrality, desiliconized rice husk powder is obtained after drying;

[0029] (3) Weigh 0.4 kg of desiliconized rice husk powder, add 1 kg of H 3 PO 4 The solution was mixed evenly and immersed for 24 hours; then placed in a nitrogen atmosphere, heated to 500 ° C, activated for 8 hours; cooled at room temperature, washed with deionized water until neutral, and dried to obtain rice husk activated carbon;

[0...

Embodiment 3

[0033] (1) Weigh 10kg of rice husk, wash, dry, crush, immerse in a hydrochloric acid solution with a mass fraction of 5%, stir at room temperature for 3 hours, filter out the rice husk, wash with deionized water until neutral, and dry to obtain impurity-removed rice shell powder;

[0034] (2) Weigh 4kg of impurity-removed rice husk powder, add 20kg of NaOH solution with a molar concentration of 4mol / L, place it in a high-pressure reactor, heat up to 150°C, keep it warm for 18h, and filter; the filtrate is set aside, and the filter residue is washed with deionized water To neutrality, desiliconized rice husk powder is obtained after drying;

[0035] (3) Weigh 0.9 kg of desiliconized rice husk powder, add 3 kg of H 3 PO 4 The solution was mixed evenly and immersed for 36 hours, then placed in a nitrogen atmosphere, heated to 700°C, and activated for 6 hours; cooled at room temperature, washed with deionized water until neutral, and dried to obtain rice husk activated carbon; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com