Method for performing ultrasonic separation on oily wastewater with oil-soluble ferroferric oxide nanoparticles

A technology of ferroferric oxide and nanoparticles, which is applied in the intersecting field of environment and materials, and can solve the problem that the treatment method is not very effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

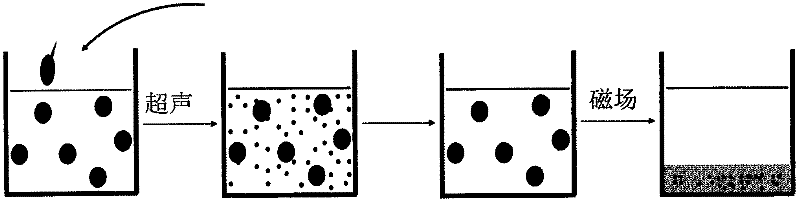

[0018] a. 20ml of oilfield wastewater is subjected to ultrasonic water-bath continuous ultrasonication;

[0019] b. Add oil-soluble iron ferric oxide nanoparticles modified by oleic acid while ultrasonicating the oil field wastewater, and disperse by ultrasonic for 5 minutes. 0.1ml;

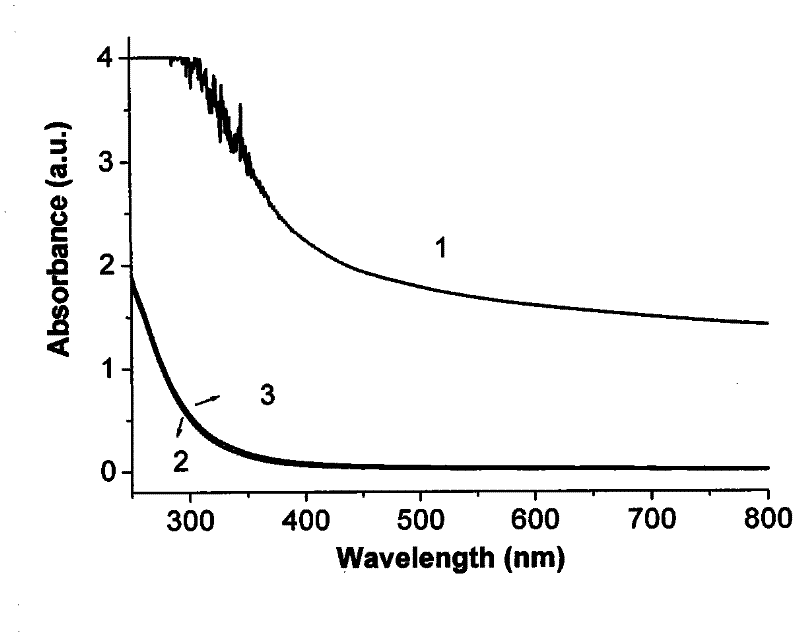

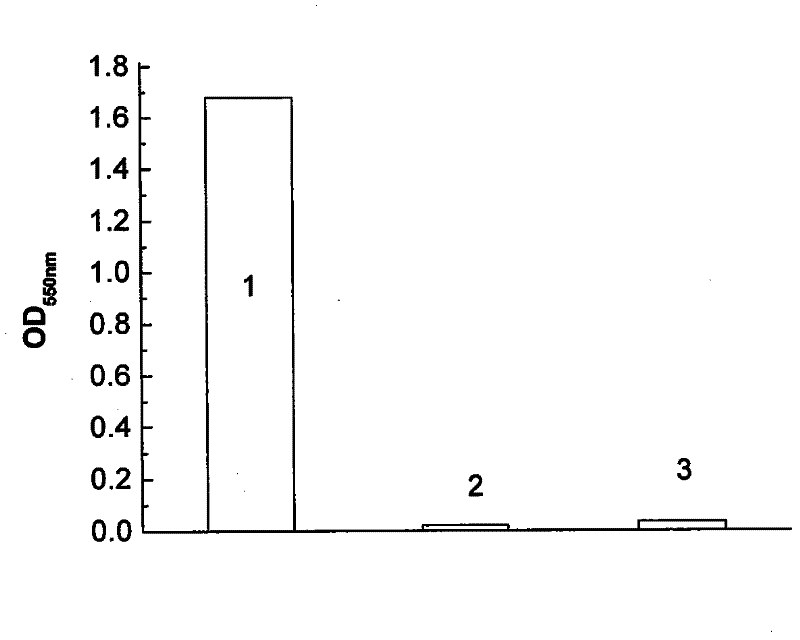

[0020] c. Perform the magnetic separation of the permanent magnet on the ultrasonic solution in step b, and scan the solution with an ultraviolet spectrophotometer. Due to the existence of micro-oil droplets, the oil field sewage has a scattering effect on visible light, so it is turbid and shows a high visible light absorption phenomenon. ( figure 2 ), especially in the ultraviolet region, because olefins will absorb here, so the ultraviolet light with a wavelength of less than 300 nanometers shows a strong absorption, and the water sample separated by ultrasonic oil-soluble ferric oxide nanoparticles no matter in the visible light The absorption range and the ultraviolet region are significa...

Embodiment 2

[0023] a, 20ml of natural gas field waste water is subjected to ultrasonic probe type intermittent ultrasonic;

[0024] b. Add oil-soluble iron ferric oxide nanoparticles modified by linoleic acid while supersonicating natural gas field wastewater, and ultrasonically disperse for 10 minutes, wherein the amount of oil-soluble iron ferric oxide nanoparticles modified by linoleic acid is per liter of oil Add 0.5ml to the waste water;

[0025] c. Perform magnetic separation of the solution after ultrasonication in step b, and scan the solution with an ultraviolet spectrophotometer. Due to the presence of micro-oil droplets, the sewage has a scattering effect on visible light, so it is turbid and shows a higher visible light absorption phenomenon. However, the water samples separated by ultrasonic oil-soluble ferric oxide nanoparticles have significantly reduced absorption in the visible light range and ultraviolet region, which can achieve the removal of micro-oil droplets in oily...

Embodiment 3

[0027] a, 20ml of mechanically processed oily waste water is subjected to ultrasonic water bath type pulse ultrasonic;

[0028] b. Add lauric acid-modified oil-soluble iron ferric oxide nanoparticles while ultrasonically processing oily wastewater, and ultrasonically disperse them for 30 minutes, wherein the amount of oil-soluble iron ferric oxide nanoparticles modified by lauric acid is per liter of oily wastewater Add 1ml to it;

[0029] c. Perform magnetic separation of permanent magnets on the solution after ultrasonication in step b, and scan the solution with an ultraviolet spectrophotometer. Due to the existence of micro-oil droplets, the sewage has a scattering effect on visible light, so it is turbid and shows a higher visible light absorption phenomenon. However, the absorption of water samples separated by ultrasonic oil-soluble ferric oxide nanoparticles is significantly reduced in both the visible light range and the ultraviolet region, which can achieve the remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com