High-solid-content interior and exterior crosslinked type water-in-water colorful granite paint and preparation method thereof

A granite coating with high solid content technology, applied in the direction of multi-color effect coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient stability of color particles, low coating amount, and unsightly appearance, etc., and achieve various Excellent performance, high spreading rate, strong weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

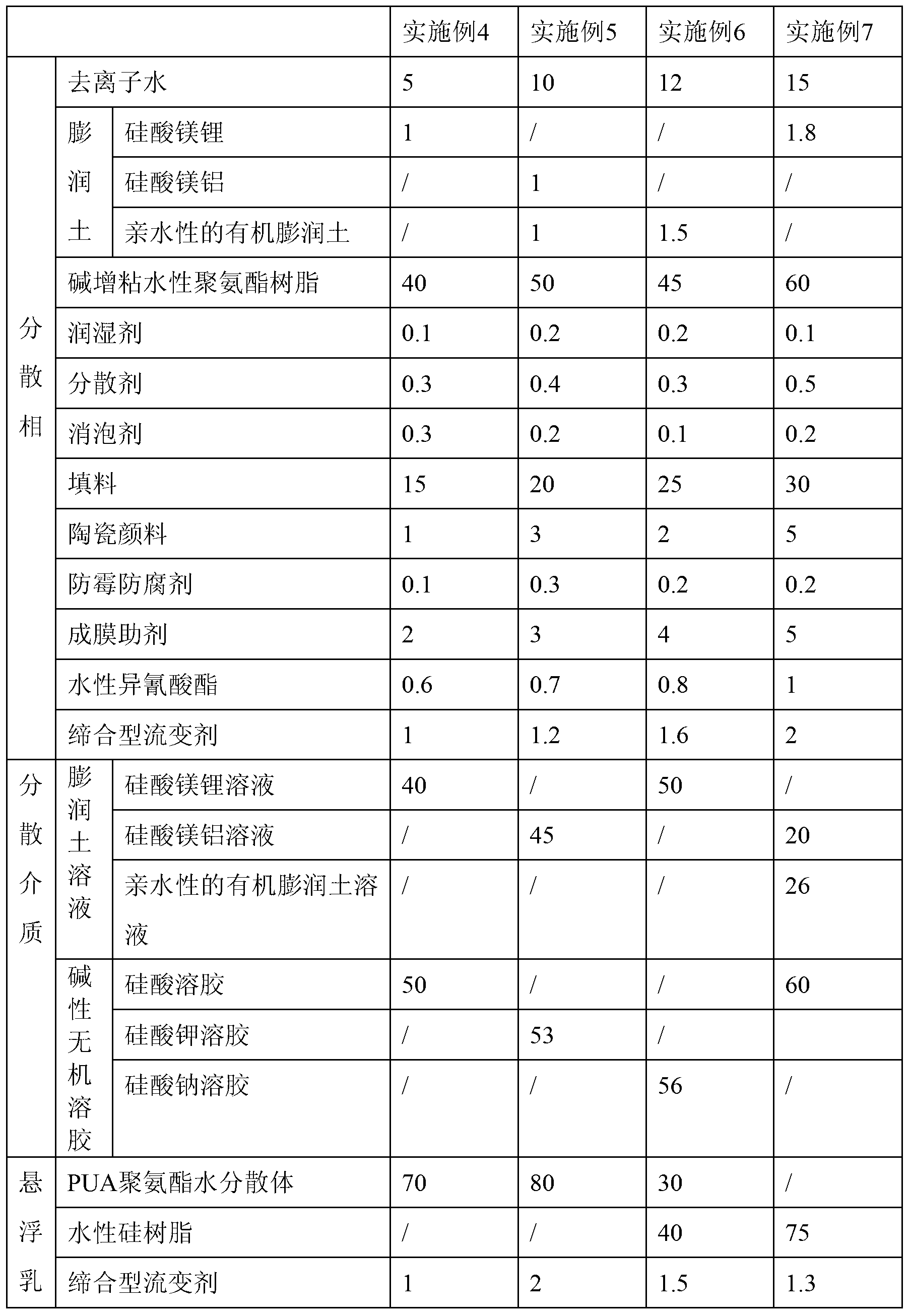

[0038] Example 1: The high solid content internal and external linking type water-in-water colorful granite paint of this example includes a weight ratio of dispersed phase, dispersion medium and suspoemulsion of 55:20:25.

[0039] The components and parts by weight of the dispersed phase are as follows:

[0040] 10 parts of deionized water, 2 parts of hydrophilic organic bentonite, 55 parts of alkali-tackified water-based polyurethane resin, 0.1 part of wetting agent, 0.3 part of dispersing agent, 0.3 part of defoamer, 22 parts of filler, 3 parts of ceramic pigment, 0.2 parts of anti-mildew preservative, 4 parts of coalescent, 1 part of water-based isocyanate, 2 parts of associative rheology agent.

[0041] The components and parts by weight of the dispersion medium are:

[0042] Bentonite solution (hydrophilic organic bentonite 5% solution) (weight percentage) 40 parts, alkaline inorganic sol (sodium silicate sol) 60 parts.

[0043] The components and parts by weight of the ...

Embodiment 2

[0059] Embodiment 2: The basic process of this embodiment is the same as that of Embodiment 1, but the difference is that the high solid content internal and external linking type water-in-water colorful granite coating includes dispersed phase, dispersion medium and suspoemulsion, and the weight ratio between them is 50: 25:25.

[0060] The components and parts by weight of the dispersed phase are as follows:

[0061] 10 parts of deionized water, 2 parts of bentonite (half of magnesium aluminum silicate and half of hydrophilic organic bentonite), 60 parts of alkali-tackified water-based polyurethane resin, 0.1 part of wetting agent, 0.5 part of dispersant, and 0.3 part of defoaming agent , 16 parts of fillers, 3 parts of ceramic pigments, 0.3 parts of anti-mildew preservatives, 5 parts of film-forming aids, 0.8 parts of water-based isocyanate, and 2 parts of associative rheological agents.

[0062] The components and parts by weight of the dispersion medium are:

[0063] Be...

Embodiment 3

[0066] Embodiment 3: The basic process of this embodiment is the same as that of Embodiment 1. The difference is that the high solid content internal and external linking type water-in-water colorful granite coating includes a dispersed phase, a dispersion medium and a suspoemulsion, and the weight ratio between them is 60: 20:20.

[0067] The components and parts by weight of the dispersed phase are as follows:

[0068] 10 parts of deionized water, 2 parts of bentonite (half of lithium magnesium silicate and half of hydrophilic organic bentonite), 54 parts of alkali-tackified water-based polyurethane resin, 0.2 part of wetting agent, 0.5 part of dispersant, and 0.3 part of defoamer , 20 parts of fillers, 5 parts of ceramic pigments, 0.2 parts of anti-mildew preservatives, 5 parts of film-forming aids, 0.8 parts of water-based isocyanates, and 2 parts of associative rheological agents.

[0069] The components and parts by weight of the dispersion medium are as follows:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com