Preparation method of nano yttrium aluminum garnet fluorescent powder

A technology for yttrium aluminum garnet and phosphor powder, which is applied in the field of preparing nanometer yttrium aluminum garnet phosphor, can solve the problems of wide particle size distribution, powder agglomeration, and high preparation cost, and achieves narrow particle size distribution, complete crystal form, and high technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

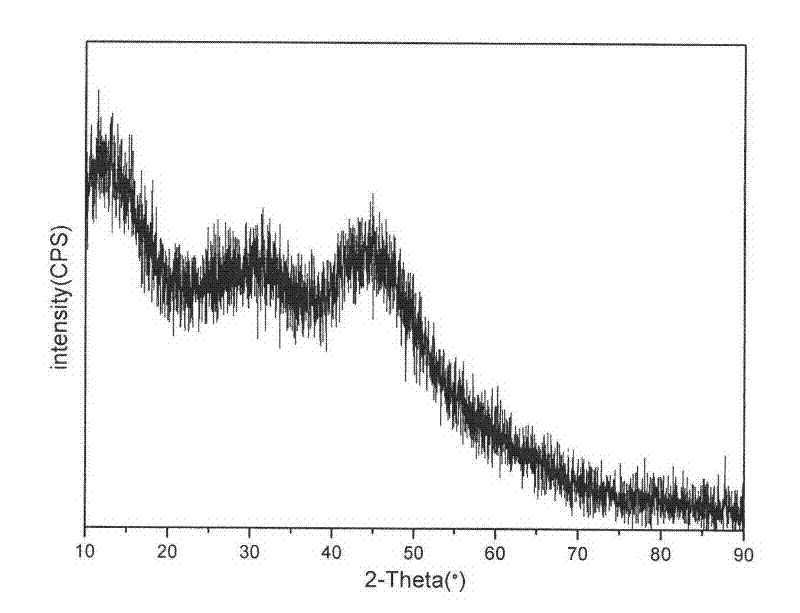

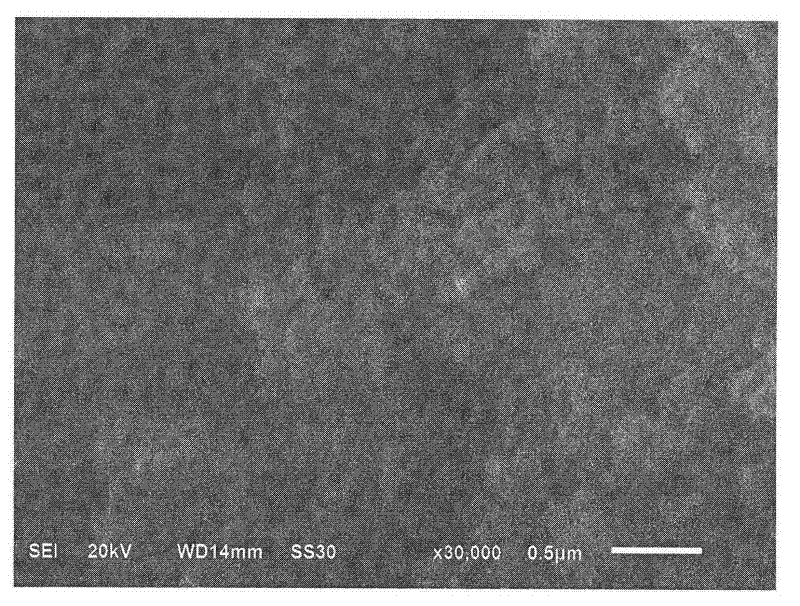

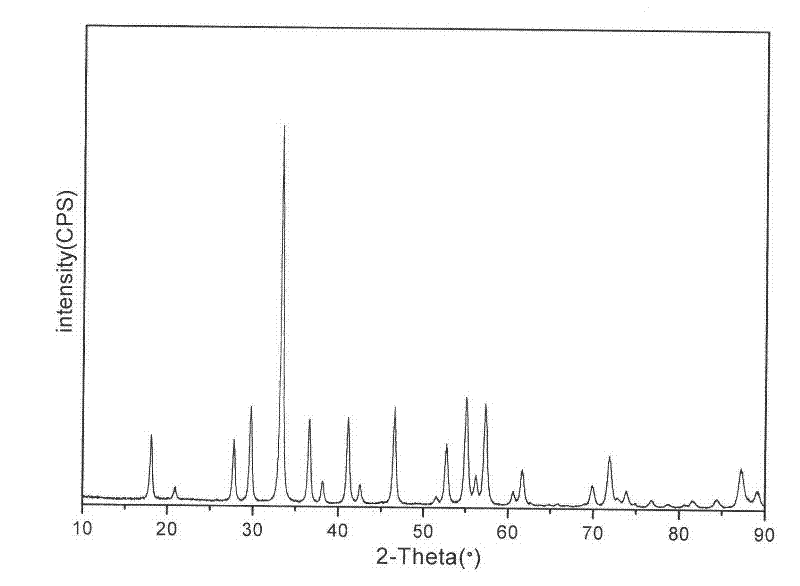

[0050] Take 21.30 grams of aluminum nitrate and 16.5 grams of yttrium nitrate according to a molar ratio of 5:3 and mix them uniformly, add deionized water to prepare a 2L mixed solution, and make a mother solution with a total cation concentration of 0.16mol / L, and use a spiral channel type rotating bed ultra The gravity reactor generates a supergravity field, reacts and circulates in the supergravity field, adds weak alkali alcohol aqueous solution to the supergravity field reactor, and controls the pH of the solution at 7.0-8.0 to obtain a suspension. The resulting suspension was aged at 60°C for 2 h, then filtered with suction, and washed three times with deionized water. Add the filter cake to 200ml of absolute ethanol, and filter with suction after ultrasonic vibration. Microwave drying at 60°C for 4h yielded a loose precursor. The obtained precursor was placed in a microwave field, and the temperature was raised from room temperature to 1000° C. for 2 hours with a prog...

Embodiment 2

[0057] Get 21.30 grams of aluminum nitrate and 16.50 grams of yttrium nitrate according to the molar ratio of 5:3 and mix evenly, add deionized water and be mixed with 2L of mixed solution, be made into the mother liquor that total cation concentration is 0.16mol / L, circulate in the supergravity field, Add a weak alkali alcohol aqueous solution to control the pH value of the solution at 7.0-8.0 to obtain a suspension. The resulting suspension was aged at 60°C for 2 h, then filtered with suction, and washed three times with deionized water. Add the filter cake to 200ml of absolute ethanol, and filter with suction after ultrasonic vibration. Microwave drying at 60°C for 4h yielded a loose precursor. The obtained precursor is placed in a microwave field, and the temperature is rapidly and directly raised from room temperature to 1000° C., and kept for 2 hours to obtain a loose yttrium aluminum garnet phosphor.

[0058] Microwave Calcination:

[0059] The method is as follows: ...

Embodiment 3

[0061] The nano-yttrium aluminum garnet phosphor was prepared according to the same method as in Example 1, except that the holding time was set to 0.5 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com