Preparation method of silica gel loaded polyhydroxyl chelating resin for highly effective boron removal

A technology of chelating resin and polyhydroxyl, which is applied in the field of preparation of chelating resin, can solve the problems of complex synthesis process, low adsorption capacity and high cost, and achieve the effects of large adsorption capacity, improved adsorption capacity and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

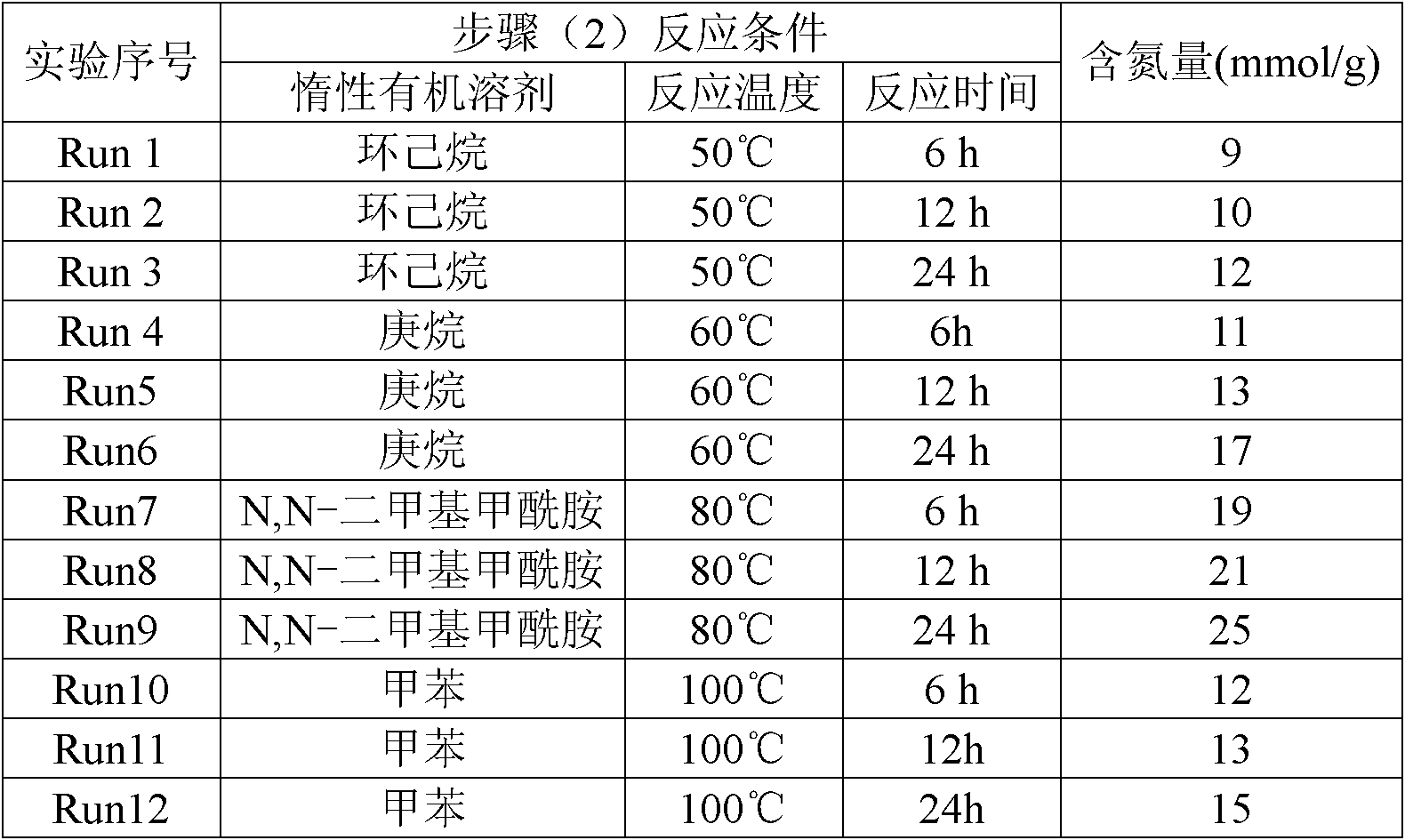

[0027] Embodiment 1 adopts different inert organic solvents to prepare meglumine modified silane coupling agent

[0028] (1) Take 30g of chromatographically packed silica gel in a 500ml three-necked bottle, add 1mol / L HNO 3 The solution was 200ml, mechanically stirred at 50°C for 6h, and after the reaction, the solid product was obtained by suction filtration, which was washed with deionized water and methanol until neutral, and dried at room temperature for 12h to obtain activated silica gel.

[0029] (2) Add 20g of meglumine and 200ml of inert organic solvent to a 500ml three-necked flask, mechanically stir, and heat in an oil bath to raise the temperature of the reaction system to 50-100°C; 40ml of inert organic solvent and 30ml of 3-(2,3-cyclo Oxypropoxy)propyltrimethoxysilane was mixed evenly and then dropped into the three-neck flask dropwise. During the whole reaction process, the system temperature was kept at 80° C., and the nitrogen atmosphere was refluxed for 24 hou...

Embodiment 2

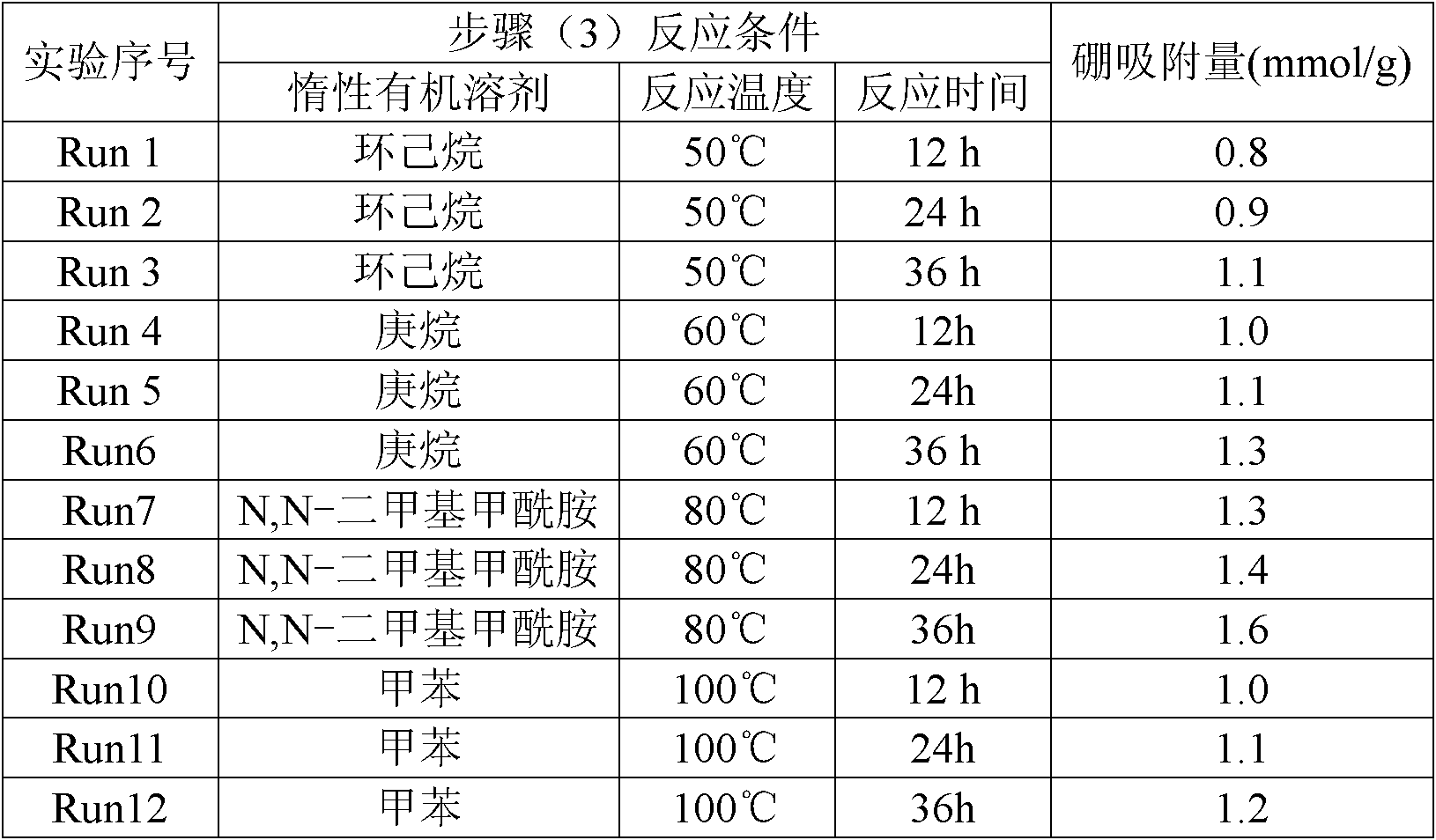

[0033] Example 2 Using different inert organic solvents to prepare silica gel-loaded polyhydroxyl efficient boron-removing chelating resins

[0034] (1) Take 30g of chromatographically packed silica gel in a 500ml three-necked bottle, add 1mol / L HNO 3 The solution was 200ml, mechanically stirred at 50°C for 6h, and after the reaction, the solid product was obtained by suction filtration, which was washed with deionized water and methanol until neutral, and dried at room temperature for 12h to obtain activated silica gel.

[0035] (2) Take 20g meglumine and 200ml N,N-dimethylformamide and add them to a 500ml three-necked flask, stir mechanically, heat the oil bath to raise the temperature of the reaction system to 80°C; 40ml N,N-dimethylformamide and 30ml of 3-(2,3-glycidoxy)propyltrimethoxysilane was mixed evenly and then dropped into the three-necked bottle drop by drop. During the whole reaction process, the system temperature was kept at 80°C, and the nitrogen atmosphere wa...

Embodiment 3

[0039] Example 3 Using different silane coupling agents to prepare silica gel-loaded polyhydroxyl efficient boron-removing chelating resins

[0040] (1) Take 30g of chromatographically packed silica gel in a 500ml three-necked bottle, add 1mol / L HNO 3 The solution was 200ml, mechanically stirred at 50°C for 6h, and after the reaction, the solid product was obtained by suction filtration, which was washed with deionized water and methanol until neutral, and dried at room temperature for 12h to obtain activated silica gel.

[0041] (2) Take 20g meglumine and 200ml N,N-dimethylformamide and add them to a 500ml three-necked flask, stir mechanically, heat the oil bath to raise the temperature of the reaction system to 80°C; 40ml N,N-dimethylformamide and 30ml of silane coupling agent was mixed evenly and then dropped into the three-neck bottle drop by drop. During the whole reaction process, the temperature of the system was kept at 80°C, and the nitrogen atmosphere was refluxed fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com