Method for synthesizing busulfan

A synthesis method and busulfan technology are applied in the preparation of sulfonates, organic chemistry, etc., and can solve the problems of difficulty in obtaining injection busulfan samples and difficult to remove.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

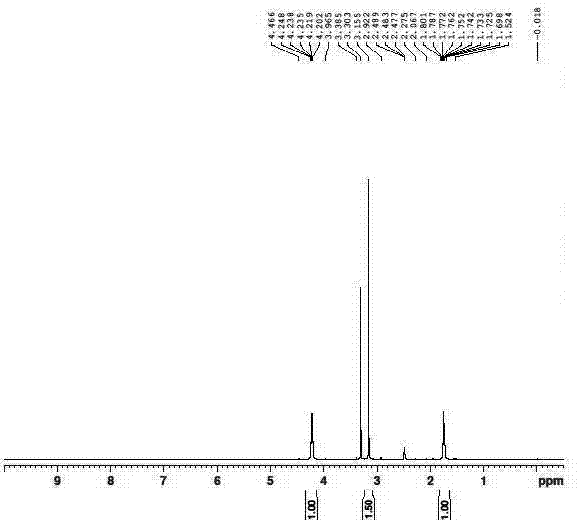

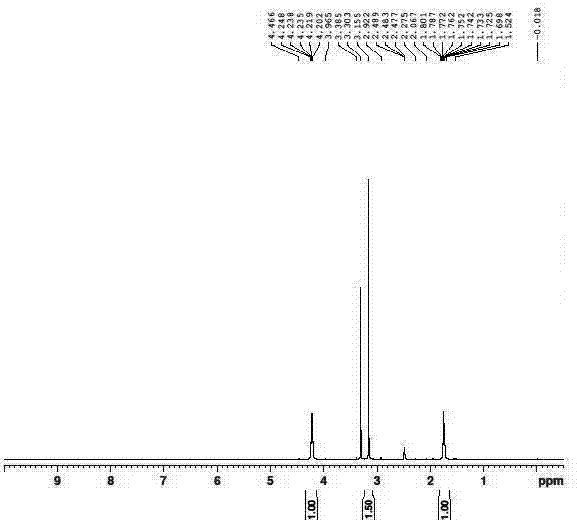

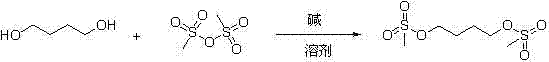

[0017] Embodiment 1, a kind of synthetic method of busulfan, it uses 1,4-butanediol, methanesulfonic anhydride is main raw material, with triethylamine, pyridine, diethylisopropylamine or sodium bicarbonate At least one kind of base is used as a solvent with acetone, tetrahydrofuran, acetonitrile or ether, and the entire reaction process is carried out under nitrogen protection; the specific steps are: add methanesulfonic anhydride in the reaction vessel, add a solvent to dissolve, and wait until the methanesulfonic anhydride is completely dissolved Finally, cool the system down to -20°C, add 1,4-butanediol and alkali to the solvent to dissolve, mix well and add the mixture dropwise to the above system, and maintain the temperature in the system at -20°C during the dropwise addition. ℃; then stirred at room temperature, suction filtered, and the filter cake was washed with deionized water and solvent to obtain the crude product of white solid busulfan; wherein: the molar ratio ...

Embodiment 2

[0018] Embodiment 2, a kind of synthetic method of busulfan, it uses 1,4-butanediol, methanesulfonic anhydride is main raw material, with triethylamine, pyridine, diethylisopropylamine or sodium bicarbonate At least one kind of base is used as a solvent with acetone, tetrahydrofuran, acetonitrile or ether, and the entire reaction process is carried out under nitrogen protection; the specific steps are: add methanesulfonic anhydride in the reaction vessel, add a solvent to dissolve, and wait until the methanesulfonic anhydride is completely dissolved Finally, cool down the system to 5°C, add 1,4-butanediol and alkali into the solvent to dissolve, mix well and add the mixture dropwise to the above system, and maintain the temperature in the system at 35°C during the dropping process; Then stir at room temperature, filter with suction, and wash the filter cake with deionized water and solvent to obtain the crude product of white solid busulfan; wherein: the molar ratio of 1,4-buta...

Embodiment 3

[0020] Embodiment 3, a kind of synthetic method of busulfan, it uses 1,4-butanediol, methanesulfonic anhydride is main raw material, with triethylamine, pyridine, diethylisopropylamine or sodium bicarbonate At least one kind of base is used as a solvent with acetone, tetrahydrofuran, acetonitrile or ether, and the entire reaction process is carried out under nitrogen protection; the specific steps are: add methanesulfonic anhydride in the reaction vessel, add a solvent to dissolve, and wait until the methanesulfonic anhydride is completely dissolved Finally, cool down the system to 0°C, add 1,4-butanediol and alkali into the solvent to dissolve, mix well and add the mixture dropwise to the above system, and maintain the temperature in the system at -5°C during the dropping process Then stir at room temperature, filter with suction, and wash the filter cake with deionized water and solvent to obtain the crude product of white solid busulfan; wherein: the molar ratio of 1,4-butan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com