Preparation method for polycarboxylic acid water reducer with strong adaptability

A polycarboxylate-based, adaptable technology, applied in the field of concrete water-reducing agents, can solve problems such as bleeding, segregation, and differences in cement adaptability, and achieve excellent product performance, reasonable preparation process, and good slump performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

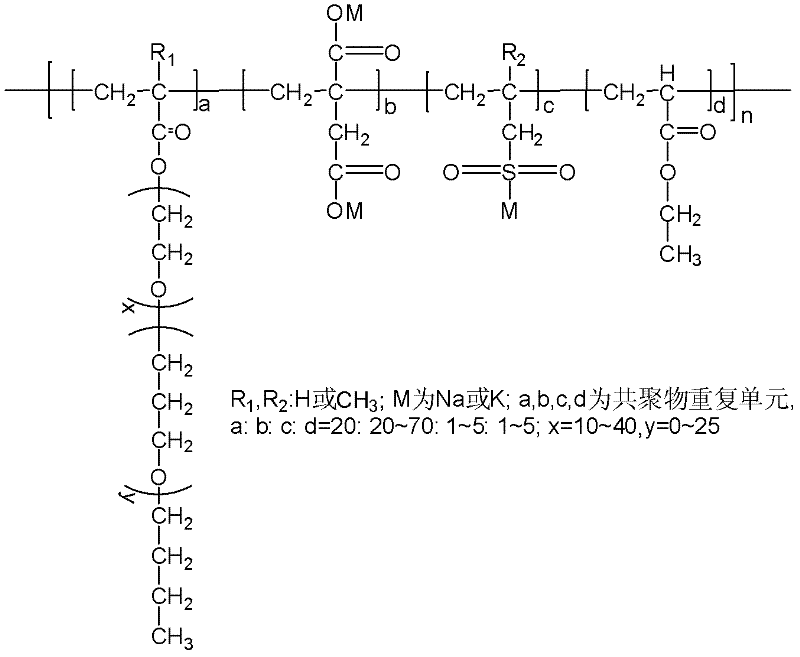

Method used

Image

Examples

Embodiment 1

[0019] 1) Preparation of macromer butanol methacrylate random polyether ester

[0020] Add 65 parts of butanol atactic polyether and 0.50 parts of hydroquinone into the reaction kettle in parts by mass, stir and raise the temperature to 60°C, slowly add 10.30 parts of methacrylic acid and 2.30 parts of concentrated sulfuric acid dropwise, and keep warm for half an hour Raise the temperature to 90°C, add 34 parts of cyclohexane, continue to reflux for 6 hours, carry out distillation to recover cyclohexane, and then cool to room temperature to obtain the macromonomer butanol atactic polyether methacrylate;

[0021] 2) Preparation of strong adaptability and high efficiency polycarboxylate water reducer

[0022] Add 18 parts of macromonomer butanol atactic polyether methacrylate and 30 parts of deionized water in parts by mass into a reactor with a stirring device;

[0023] 1.30 parts of itaconic acid, 0.10 parts of sodium methacrylate and 0.05 parts of ethyl acrylate were dissol...

Embodiment 2

[0027] 1) Preparation of macromer butanol methacrylate random polyether ester

[0028] Add 70 parts of butanol atactic polyether and 0.60 parts of hydroquinone into the reaction kettle in parts by mass, stir and raise the temperature to 60°C, slowly add 13.56 parts of methacrylic acid and 2.30 parts of concentrated sulfuric acid dropwise, and keep warm for half an hour Raise the temperature to 95°C, add 36 parts of cyclohexane, continue to reflux for 6 hours, carry out distillation to recover cyclohexane, and then cool to room temperature to obtain the macromonomer butanol atactic polyether methacrylate;

[0029] 2) Preparation of strong adaptability and high efficiency polycarboxylate water reducer

[0030] In parts by mass, 21 parts of macromonomer butanol atactic polyether methacrylate and 35 parts of deionized water are added to a reactor with a stirring device;

[0031] 2.60 parts of itaconic acid, 0.21 parts of sodium methacrylate and 0.10 parts of ethyl acrylate were d...

Embodiment 3

[0035] 1) Preparation of macromer butanol methacrylate random polyether ester

[0036] Add 75 parts of butanol atactic polyether and 0.65 parts of hydroquinone into the reaction kettle in parts by mass, stir and raise the temperature to 60°C, slowly add 16.00 parts of methacrylic acid and 2.30 parts of concentrated sulfuric acid dropwise, and keep warm for half an hour Raise the temperature to 100°C, add 38 parts of cyclohexane, continue to reflux for 6 hours, carry out distillation to recover cyclohexane, and then cool to room temperature to obtain the macromonomer butanol atactic polyether methacrylate;

[0037] 2) Preparation of strong adaptability and high efficiency polycarboxylate water reducer

[0038] Add 24 parts of macromonomer butanol atactic polyether methacrylate and 40 parts of deionized water into a reactor with a stirring device in parts by mass;

[0039] 3.90 parts of itaconic acid, 0.41 parts of sodium methacrylate and 0.15 parts of ethyl acrylate were disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com