Salt-storing deicing material special for asphalt pavement and preparation method thereof

A technology for asphalt pavement and salt storage, applied in the field of materials, can solve the problems of unsatisfactory deicing effect of snow-melting and deicing agent, shortening the service life of roads, destroying plants around roads, etc., so as to improve long-term deicing effect, good application effect, The effect of reducing environmental pollution and road damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

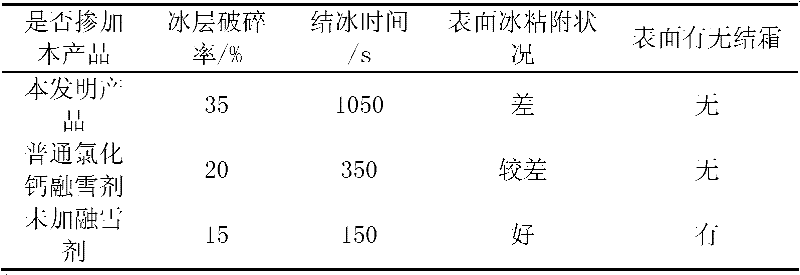

Embodiment 1

[0034] Taking the production of 1000g salt-storage type asphalt pavement special deicing material as an example, the dosage of each raw material is as follows (each component in the system is commercially available):

[0035] Inorganic freezing point depression main agent: 400g;

[0036] Organic auxiliary freezing point depressant: 100g;

[0037] Freezing delay agent: 100g;

[0038] Ice softener: 100g;

[0039] Release stabilizer: 300 g.

[0040] The main inorganic freezing point depressant is selected from anhydrous calcium chloride with a fineness of 20-200 mesh.

[0041] Described organic auxiliary freezing point depressant is made up of ethylene glycol and urea, and mass ratio is ethylene glycol: urea=100: 65; Described freezing retarder is made up of sodium polyacrylate, maleic anhydride isobutylene polymer, and mass ratio is Sodium polyacrylate: maleic anhydride isobutylene polymer=100:90; the ice softener is 1,6-hexanediol diacrylate; the release stabilizer is P.O 4...

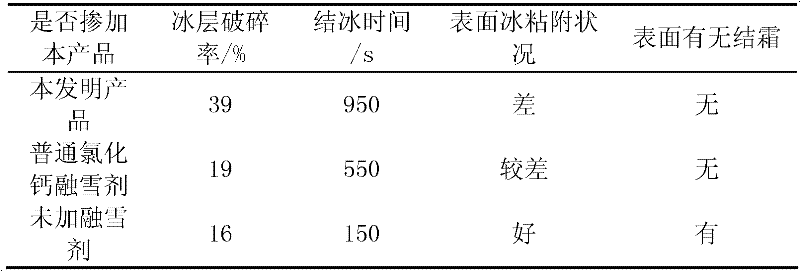

Embodiment 2

[0047] Taking the production of 1000g salt-storage type asphalt pavement special deicing material as an example, the dosage of each raw material is as follows (each component in the system is commercially available):

[0048] Inorganic freezing point depression main agent: 400g;

[0049] Organic auxiliary freezing point depressant: 150g;

[0050] Freezing delay agent: 50g;

[0051] Ice softener: 50g;

[0052] Release stabilizer: 350 g.

[0053] The main inorganic freezing point depressant is calcium chloride with a fineness of 20-200 mesh.

[0054] Described organic auxiliary freezing point depressant is made up of ethylene glycol; Described freezing retarder is made up of sodium polyacrylate, maleic anhydride isobutylene polymer, and mass ratio is sodium polyacrylate: maleic anhydride isobutylene polymer=100:120 ; The ice softener is 1,6-hexanediol diacrylate; the release stabilizer is P.O 42.5 ordinary Portland cement and hydrated lime, and the mass ratio is ordinary Por...

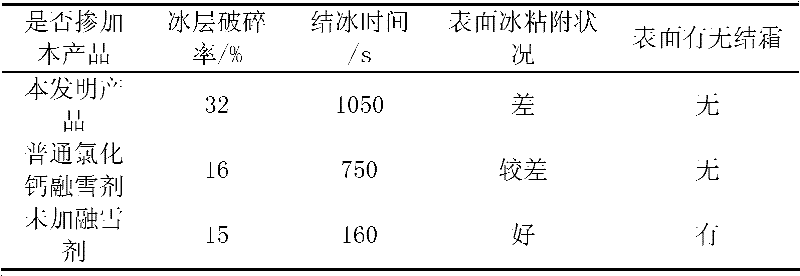

Embodiment 3

[0062] Taking the production of 1000g salt-storage type asphalt pavement special deicing material as an example, the dosage of each raw material is as follows (each component in the system is commercially available):

[0063] Inorganic freezing point depression main agent: 300g;

[0064] Organic auxiliary freezing point depressant: 100g;

[0065] Freezing delay agent: 50g;

[0066] Ice softener: 50g;

[0067] Release stabilizer: 500 g.

[0068] The main inorganic freezing point depressant is selected from anhydrous calcium chloride with a fineness of 20-200 mesh.

[0069] The organic auxiliary freezing point depressant is composed of ethylene glycol and 1-2 propylene glycol, and the mass ratio is ethylene glycol: 1-2 propylene glycol=100: 120; the described freezing delay agent is composed of sodium polyacrylate; the ice The layer softener is propylene glycol methyl ether acetate; the release stabilizer is P.O 42.5 cement and slaked lime, and the mass ratio is cement:slake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com