Core shell structure composite fiber based on carbon nano tube and preparation method and application thereof

A technology of carbon nanotube fibers and composite fibers, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, and material electrochemical variables. Sensitivity, the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

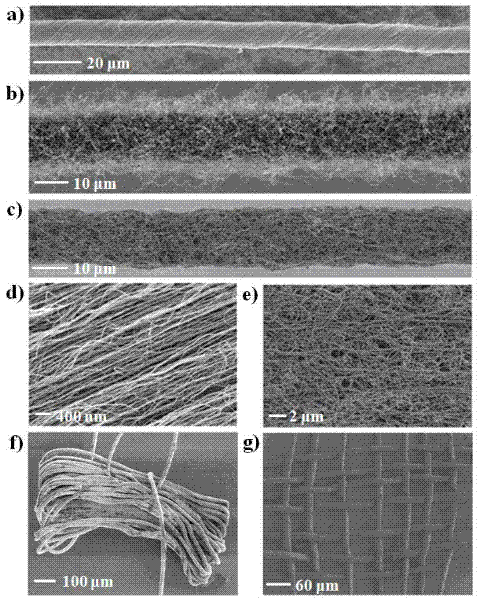

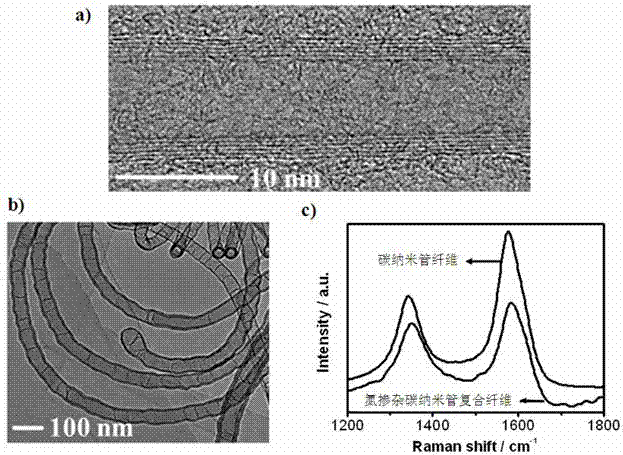

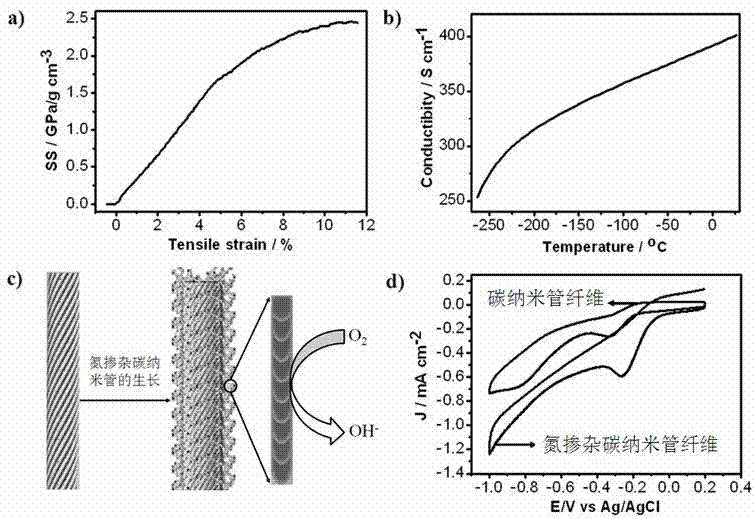

[0048] like Figure 7 Shown is a schematic diagram of the growth of nitrogen-doped carbon nanotubes on pure carbon nanotube fibers. First, FeCl 3 It is coated on the carbon nanotube fiber by soaking the carbon nanotube fiber in 0.1mol FeCl 3 aqueous solution, and then evaporate the water to achieve. The synthesized fibers were mounted on ceramic boats in a tube furnace in which a mixture of argon (560 ± 10 sccm) and hydrogen (35 ± 5 sccm) was used as the gas phase carrier. Detailed temperature changes during the growth process such as Figure 8 shown. All in all, the furnace temperature rises from room temperature to 900±10°C in about 20 to 25 minutes under the gas phase carrier and then stabilizes at 900±10°C for about 40 to 60 minutes. 3 reduced to Fe. Then, ethylenediamine is introduced into the furnace as a carbon source and a nitrogen source to grow nitrogen-doped carbon nanotubes for 5-30 minutes. After the experiment, the ethylenediamine was turned off and the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com