Preparation method of magnesium-doped lithium nickel cobalt oxide anode material for lithium ion battery

A technology for lithium-magnesium-nickel-cobaltate and lithium-ion batteries, which is applied in the field of preparation of high-density magnesium-nickel-nickel-cobaltate positive electrode materials for lithium-ion batteries, can solve the problems of complex process, high difficulty in industrialization, and large crystal size, and achieve The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

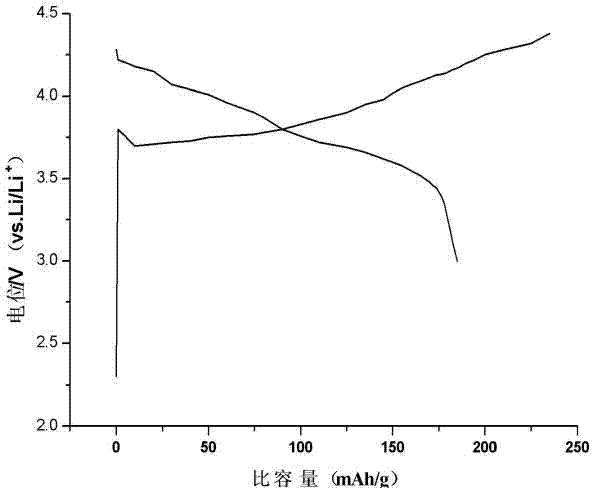

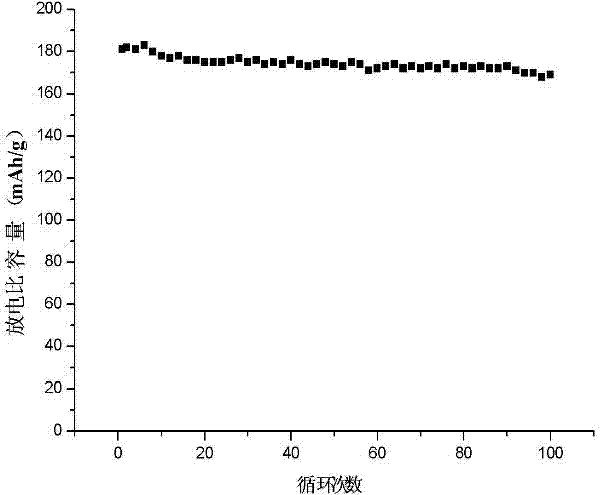

Embodiment 1

[0032] (1) According to the ratio of Li:Ni:Co:Mg molar ratio of 1.01:0.8:0.15:0.05, weigh the reactant raw material LiOH·H with high purity 2 O, Ni(OH) 2 、Co 3 o 4 , MgO;

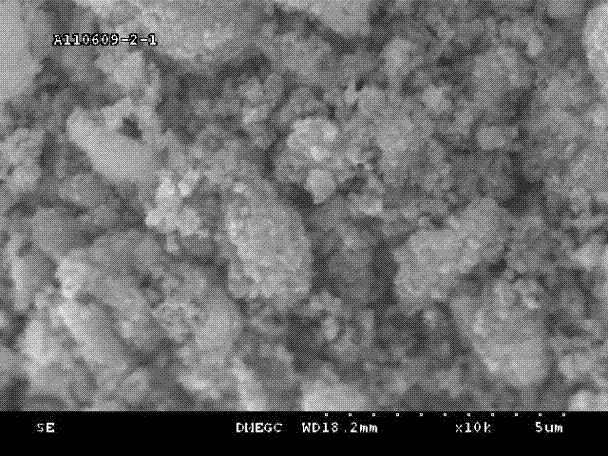

[0033] (2) The prepared raw materials are prepared according to the proportion: alcohol: water: zirconium ball = 1: 0.05: 2: 4 (wt%), and the wet ball milling is carried out for 10 hours, and the particle size of the mixed slurry is 0.5 ~1.5μm;

[0034] (3) Spray drying the mixed slurry;

[0035] (4) Put the dry material into a ceramic bowl, heat it in a tube furnace, and heat it up in an oxygen atmosphere of 1.5 atmospheres of oxygen pressure for preheating treatment. The heating rate is 15°C / min, and it is kept at 400°C. Pre-fired for 2 hours to obtain pre-fired material;

[0036] (5) Crush the pre-fired material to a particle size of 2-5 μm, add 0.5wt% PVA binder to the pre-fired material, at 1800kg / cm 3 Under pressure, pressed into a dense block;

[0037] (6) Put the compacted block into a ceramic...

Embodiment 2

[0041] (1) Weigh lithium carbonate, nickel carbonate, cobalt carbonate, and magnesium carbonate as reactant raw materials with higher purity according to the ratio of Li:Ni:Co:Mg molar ratio of 1.01:0.8:0.15:0.05;

[0042] (2) The prepared raw materials are proportioned as material: alcohol: zirconium balls = 1: 0.05: 2.5: 4 (wt%), wet ball milling for 12 hours, and the particle size of the mixed slurry is 0.5-1.5 μm;

[0043] (3) Spray drying the mixed slurry;

[0044] (4) Put the dry material into a ceramic bowl, heat it in a tube furnace, and heat it up in an oxygen atmosphere of 1.5 atmospheres of oxygen pressure for preheating treatment. The heating rate is 10°C / min, and it is kept at 450°C. Pre-fired for 2 hours to obtain pre-fired material;

[0045] (5) Crush the pre-fired material to a particle size of 2-5 μm, add 0.5wt% PVA binder to the pre-fired material, at 1800kg / cm 3 Under pressure, pressed into a dense block;

[0046] (6) Put the compacted block into the cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com