Preparation method of SOFC electrolyte surface micro-convex structure and product thereof

A micro-convex structure and electrolyte technology, applied in solid electrolyte fuel cells, circuits, fuel cells, etc., can solve the problem of blocking electron and ion transport channels, difficult to ensure chemical bonding at the same time, and difficult to ensure that the electrolyte particles in the composite cathode are separated from the cathode particles. Interconnection and other issues to achieve the effect of increasing the effective reaction area, reducing polarization, and improving electrode performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

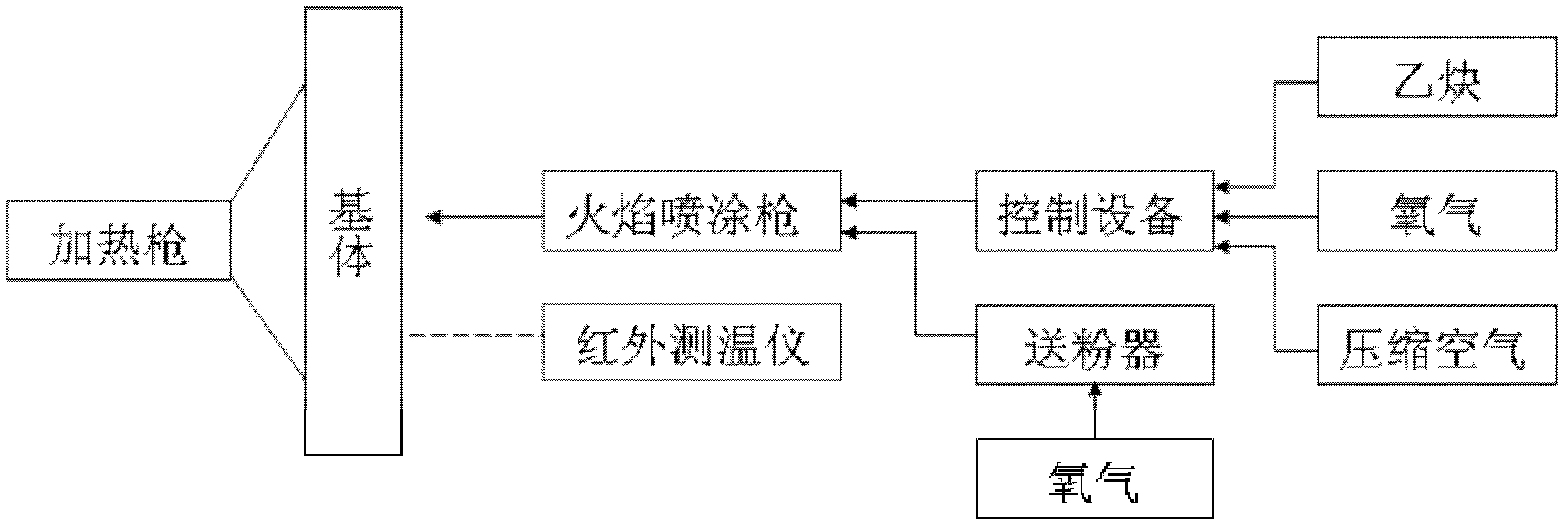

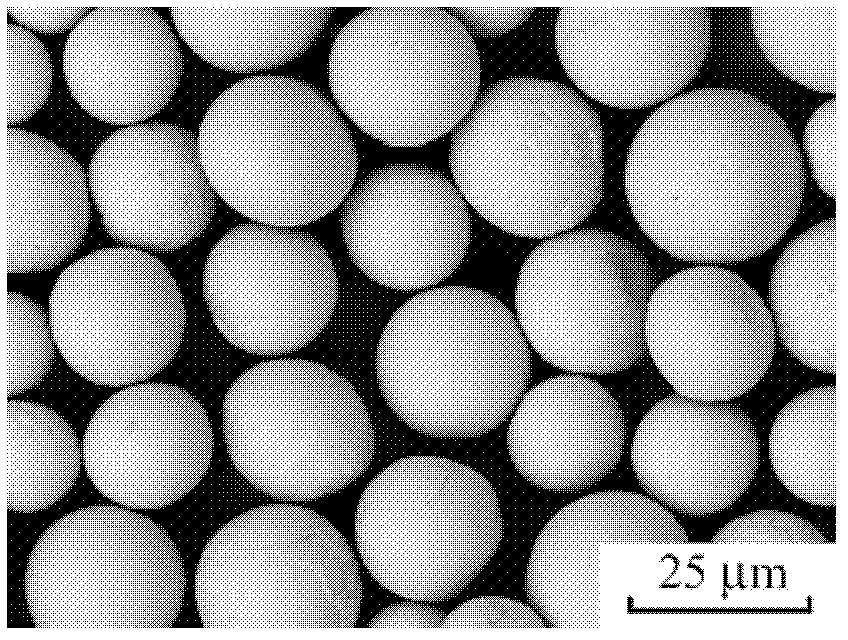

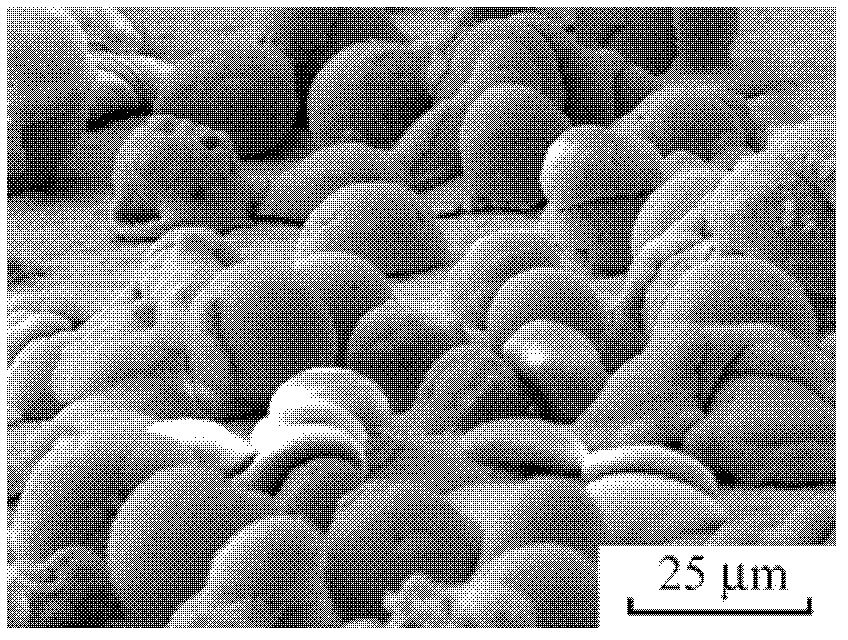

[0034] Example 1: See figure 2 , image 3 and Figure 4 As shown, on the electrolyte surface of the half-cell (including NiO / YSZ anode and YSZ electrolyte) prepared by casting method, spherical YSZ particles of 10-20 μm were used as spraying materials (as attached figure 1As shown), the spherical YSZ particles of 10-20 μm are sprayed onto the surface of the electrolyte substrate at a temperature of 600 °C by oxyacetylene flame spraying method; by controlling the parameters of the spraying, the flying speed of the particles is controlled so that the particles hit the front surface of the electrolyte surface Partial melting and most of them do not rebound, the unmelted solid particles protrude to form a particle convex structure, and the melted part combines with the electrolyte matrix to build a micro-convex structure layer composed of electrolyte materials on the surface of the existing electrolyte. Using a high-resolution electron microscope to analyze and count the cross-...

Embodiment 2

[0039] Example 2: See Figure 5 , Figure 6 and Figure 7 As shown, 5–25 μm sintered broken ScSZ (Sc 2 o 3 Stabilized ZrO 2 ) particles are spraying materials, and the oxyacetylene flame spraying method is used to spray ScSZ particles onto the surface of the electrolyte matrix at a temperature of 500°C; by controlling the parameters of the spraying, the flight speed and melting state of the particles are controlled, so that the particles hit the electrolyte surface before The surface layer is partially melted and most of it does not rebound. The unmelted solid particles protrude to form a particle convex structure, and the melted part combines with the matrix to build a micro-convex structure layer composed of electrolyte materials on the surface of the existing electrolyte. High-resolution electron microscopy is used The analysis and statistics of 50 deposited particles and the cross-section of the substrate show that the chemical combination rate is about 62%, and the su...

Embodiment 3

[0043] Example 3: See Figure 8 and Figure 9 As shown, 5–25 μm sintered broken YSZ (Y 2 o 3 Stabilized ZrO 2 ) particles are spraying materials, and the oxyacetylene flame spraying method is used to spray YSZ particles onto the surface of the electrolyte matrix at a temperature of 500°C; by controlling the parameters of the spraying, the flight speed and melting state of the particles are controlled, so that the particles hit the electrolyte surface before The surface layer is partially melted and most of it does not rebound, and the unmelted solid particles protrude to form a particle convex structure, and the melted part combines with the matrix to build a slightly convex structure layer composed of electrolyte materials on the surface of the existing electrolyte. The surface area of the structured electrolyte is doubled compared with that before preparation.

[0044] The technical parameters of oxyacetylene flame spraying in Example 3 of the present invention are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com