Method for processing instant easily-dispersed clam meat powder

A technology of mussel meat powder and a processing method, which is applied in the fields of aquatic product processing, food processing and preservation, can solve the problem of large loss and damage of mussel powder nutrient components and active substances, there is no report on the industrialized production of mussel powder products, heavy metals in meat powder, microorganisms and other problems such as exceeding the standard, to achieve the effect of improving the level of deep processing technology, delicious and convenient fast-paced life, and expanding sales channels and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

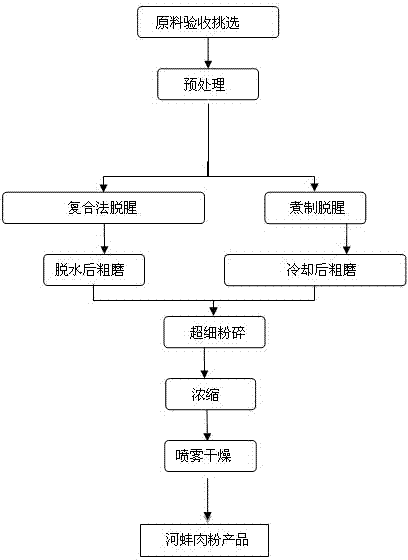

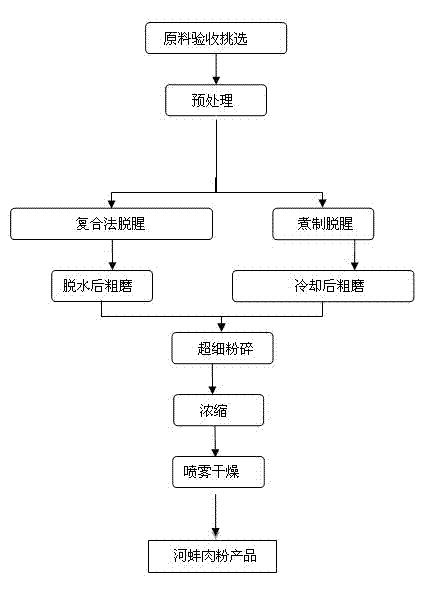

Image

Examples

Embodiment 1

[0042] Take 1000g of fresh mussels, after acceptance and selection, put them in clean water for rest and purification; then dissect the shell and take the meat, remove the mantle, stomach and surrounding viscera; rinse with running water to obtain clean muscle tissue. After pretreatment, put it into a deodorizing solution containing 0.5% by mass of salt, 0.1% by mass of citric acid and 0.2% by mass of active dry yeast powder for 60 minutes, and the mass ratio of raw materials to deodorizing solution is 1:2; After removing the deodorizing liquid by centrifugation, wash with clean water 3 times, the mass ratio of raw material to water is 1:3, and then dehydrate by centrifugation. Then use a meat grinder for coarse grinding, and then transfer to an ultrafine pulverizer for fine grinding to further refine the raw material; vacuum concentration to a solid content of 25%; use a spray dryer to spray dry the above slurry A clam meat powder product with light yellow color, uniform part...

Embodiment 2

[0044]Take 1000g of fresh mussels, after acceptance and selection, put them in clean water for rest and purification; then cut the shells to get the meat, remove the mantle, stomach and surrounding viscera; rinse with running water to obtain clean muscle tissue. After pretreatment, put it into the deodorization liquid containing 0.4% by mass percentage of salt, 0.2% by mass percentage of citric acid and 0.2% by mass percentage of active dry yeast powder for 50min, the mass ratio of raw materials and deodorization liquid is 1:2; After removing the deodorizing liquid, rinse with water for 3 times, the mass ratio of raw materials to water is 1:3, and then dehydrate by centrifugation. Then use a meat grinder for coarse grinding, and then transfer to an ultrafine pulverizer for fine grinding to further refine the raw materials; vacuum concentration to a solid content of 27%; use a spray dryer to spray dry the above slurry. A clam meat powder product with light yellow color, uniform...

Embodiment 3

[0046] Take 1000g of fresh mussels, after acceptance and selection, put them in clean water for rest and purification; then dissect the shell and take the meat; remove the mantle, stomach and surrounding viscera; rinse with running water to obtain clean muscle tissue. After pretreatment, put it into the deodorization liquid containing 0.3% by mass percentage of salt, 0.3% by mass percentage of citric acid and 0.2% by mass percentage of active dry yeast powder for 40min, the mass ratio of raw materials and deodorization liquid is 1:2; After removing the deodorizing liquid, rinse with clean water twice, the mass ratio of raw materials to water is 1:3, and then dehydrate by centrifugation. Then use a meat grinder for coarse grinding, and then transfer to an ultrafine pulverizer for fine grinding to further refine the raw materials; use vacuum concentration to a solid content of 30%; use a spray dryer to spray dry the above slurry. The clam meat powder product with light yellow co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com