Nutritious compound fertilizer of swamp cabbage

A technology of compound fertilizer and water spinach, applied in the direction of organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of inability to improve the resistance of water spinach, environmental plant pollution, and unhealthy plants, and achieve good economic benefits, less pollution, and fewer pests and diseases Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

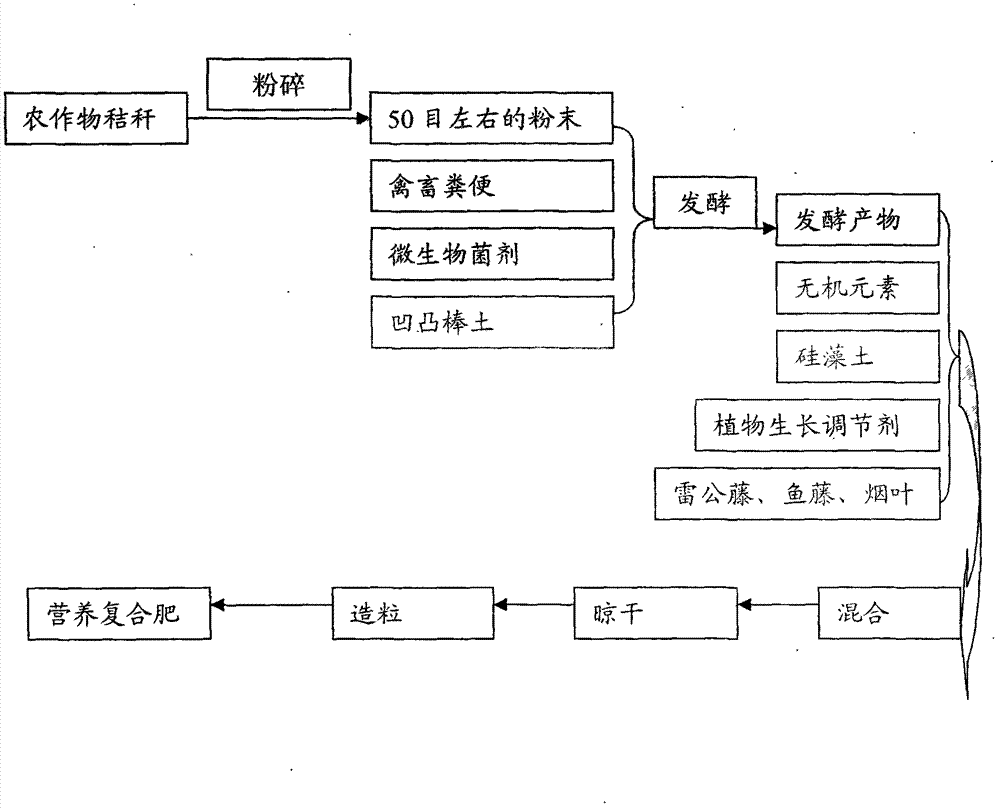

Method used

Image

Examples

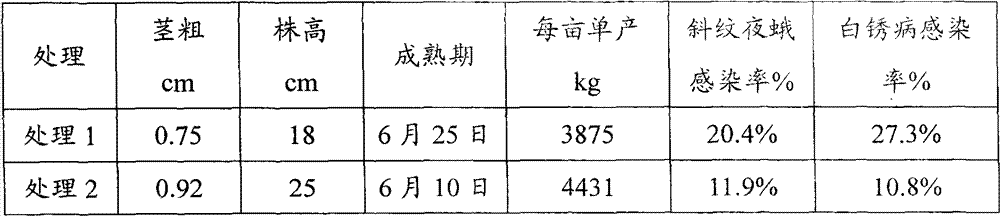

Embodiment 1

[0033] Select raw materials, each component is by weight: 5 parts of tripterygium wilfordii, 3 parts of deervine, 1 part of tobacco leaf, 20 parts of urea, 2 parts of ammonium nitrate, 1 part of potassium dihydrogen phosphate, 2 parts of potassium sulfate, 1 part of calcium nitrate 0.5 parts of magnesium sulfate, 1 part of borax, 2 parts of zinc sulfate, 3 parts of ferrous sulfate, 1 part of copper sulfate, 3 parts of diatomaceous earth, 10 parts of attapulgite, 11 parts of wheat straw, 40 parts of cattle and sheep manure mixture , 2-4 parts of microbial agent, 5 parts of brassinolide.

[0034] Use a granulator to crush wheat straw into a powder of about 50 meshes, and then mix and crush Tripterygium wilfordii, degeria, and tobacco leaves into powders of about 60 meshes.

[0035] Mix and mix cow dung, sheep dung, microbial agent, wheat straw powder, and attapulgite, pile up wet materials in the fermentation tank for fermentation, cover with plastic cloth for moisturizing and h...

Embodiment 2

[0043]Select raw materials, 6 parts of tripterygium wilfordii, 5 parts of deervine, 3 parts of tobacco leaves, 23 parts of urea, 5 parts of ammonium nitrate, 2 parts of potassium dihydrogen phosphate, 3 parts of potassium sulfate, 2 parts of calcium nitrate, 1 part of magnesium sulfate, 1 part of borax 4 parts of zinc sulfate, 5 parts of ferrous sulfate, 1.5 parts of copper sulfate, 3 parts of diatomaceous earth, 15 parts of attapulgite, 20 parts of corn cob, 55 parts of chicken and duck manure, 4 parts of microbial agent, gibberellin 5 servings. Use a granulator to pulverize the corn cob into a 60-mesh powder, and then mix and pulverize Tripterygium wilfordii, Degeria, and tobacco leaves into a 20-mesh powder.

[0044] Mix and mix chicken and duck manure, microbial agents, corn cob powder, and attapulgite, pile up wet materials in the fermentation tank for fermentation, cover with plastic cloth to keep moisture and keep warm, and control the moisture content of the fermentati...

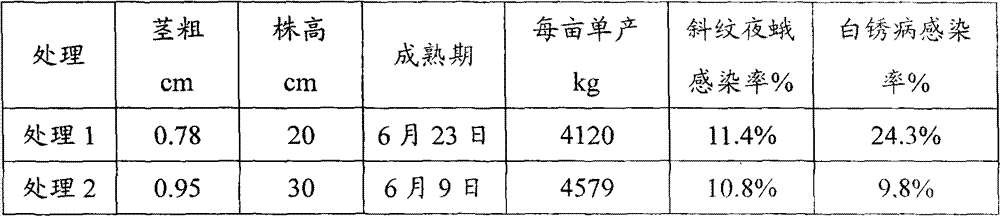

Embodiment 3

[0052] Select raw materials, 7 parts of tripterygium wilfordii, 5 parts of deervine, 3 parts of tobacco leaves, 25 parts of urea, 6 parts of ammonium nitrate, 4 parts of potassium dihydrogen phosphate, 5 parts of potassium sulfate, 2 parts of calcium nitrate, 0.5 parts of magnesium sulfate, 2 parts of borax 5 parts of zinc sulfate, 6 parts of ferrous sulfate, 1.5 parts of copper sulfate, 3 parts of diatomaceous earth, 15 parts of attapulgite, 20 parts of cotton stalk, 60 parts of cow dung, 4 parts of microbial agent, 5 parts of indole acetic acid share.

[0053] Mix and mix cow dung, microbial agent, cotton stalk powder, and attapulgite, pile up wet materials in the fermentation tank for fermentation, cover with plastic cloth to keep moisture and keep warm, control the moisture content of the fermentation mixture at 53%, after 50 hours Finally, turn the pile for the first time when the temperature in the pile reaches 60°C, and turn the pile once every 24 hours. After turning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com