Waterproof/sealing paint with aqueous resin as main body

A water-based resin and main body technology, applied in the field of coatings, can solve the problems of high price, easy peeling off of the film, poor affinity of the lipophilic surface layer to the water-based topcoat, etc., and achieve the effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

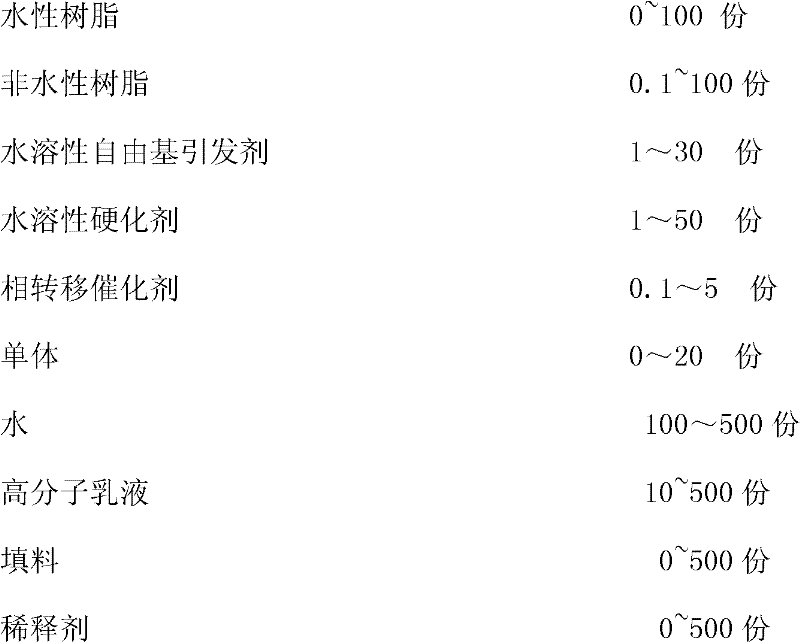

[0030] composition

[0031]

[0032]

[0033] Mix bisphenol A epoxy resin BE188 with 4,4-azobis(4-cyanovaleric acid), put it into the reaction axe, pressurize and react at 150°C for 1 hour, add water and ammonia water, and then add polyethylene Diol, with a high-speed mixer (1000rpm), to obtain milky yellow water-based epoxy resin A liquid; diethylenetriamine is B liquid. Mix liquid A and liquid B with other materials, mix with a high-speed mixer, add water to dilute to 5 times, and apply them to highly water-permeable walls, wood, metal (cast iron) and paper, and wait for the paint film to dry (approx. Ten days), drip test, water can not penetrate into the material, and the metal has no oxidation phenomenon. After the film is dry, apply a white water-based topcoat. There is no impurity seeping out of the material, and the topcoat film is white after air-drying.

Embodiment 2

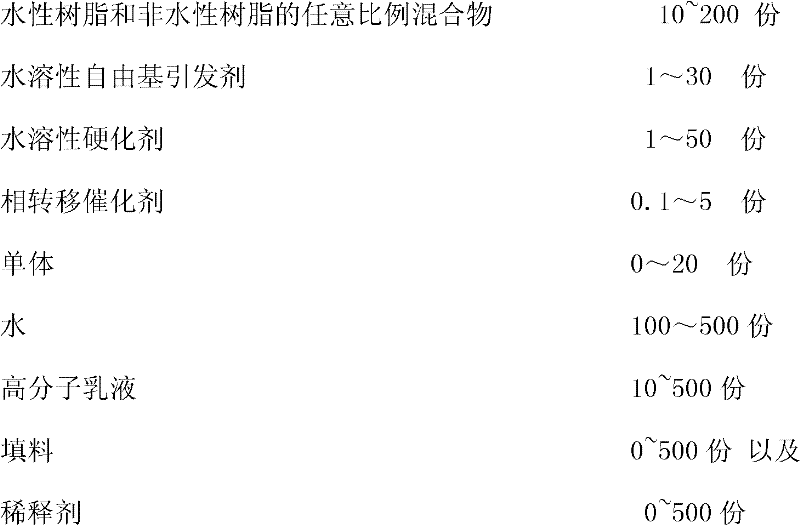

[0035] composition

[0036]

[0037] Water-based epoxy resin into ammonia, water, mixed with a high-speed mixer.

[0038]The water-soluble hardener diethylenetriamine is added to the water-soluble free radical initiator, the polymer emulsion and the quaternary ammonium salt (tetrabutylammonium chloride) are B liquid. Mix liquid A and liquid B mixed with other materials, mix with a high-speed mixer, add water to dilute to 5 times, and apply to walls with high water permeability, wood, metal (cast iron) and paper respectively, and wait for the paint film to dry. (about ten days), drip test, water can not penetrate into the material, and the metal has no oxidation phenomenon. After the film is dry, apply a white water-based topcoat. There is no impurity seeping out of the material. The topcoat film is white after air-drying ..

Embodiment 3

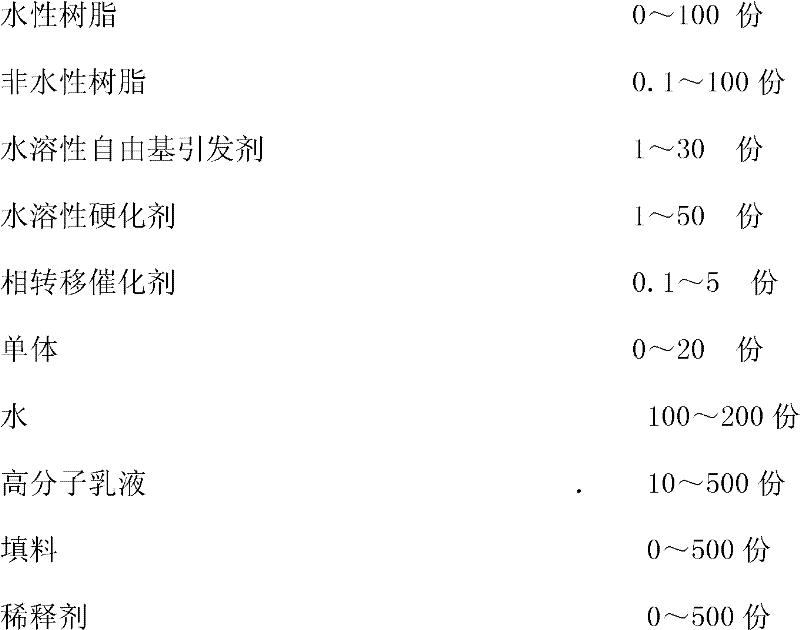

[0040] composition

[0041]

[0042] Mix water-based epoxy resin with bisphenol A epoxy resin BE188, add ammonia, water, and polyethylene glycol to form A liquid, and mix with a high-speed mixer.

[0043] Diethylenetriamine is liquid B. Mix liquid A and liquid B mixed with other materials, mix with a high-speed mixer, add water to dilute to 5 times, and apply to walls with high water permeability, wood, metal (cast iron) and paper respectively, and wait for the paint film to dry. (about ten days), drip test, water can not penetrate into the material, and the metal has no oxidation phenomenon. After the film is dry, apply a white water-based topcoat. There is no impurity seeping out of the material. The topcoat film is white after air-drying .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com