Silage and preparation method thereof

A technology for silage and raw materials, which is applied in the field of silage and its preparation, can solve the problems of imperfect selection of auxiliary materials, low lignin, rough texture and the like, and achieves the improvement of nutrient composition and palatability of feed, good nutritional value and palatability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of silage, purchasing the processing residue of bamboo shoots, corn flour, salt and urea as raw materials; wherein the processing residue of bamboo shoots is crushed, squeezed and dehydrated (the moisture content of the processing residue of bamboo shoots after dehydration is 67%), by weight Adding 0.5% of table salt, 3% of cornmeal and 1% of urea, which account for the processing residue of bamboo shoots, stirring and mixing, bundling, covering and fermenting.

Embodiment 2

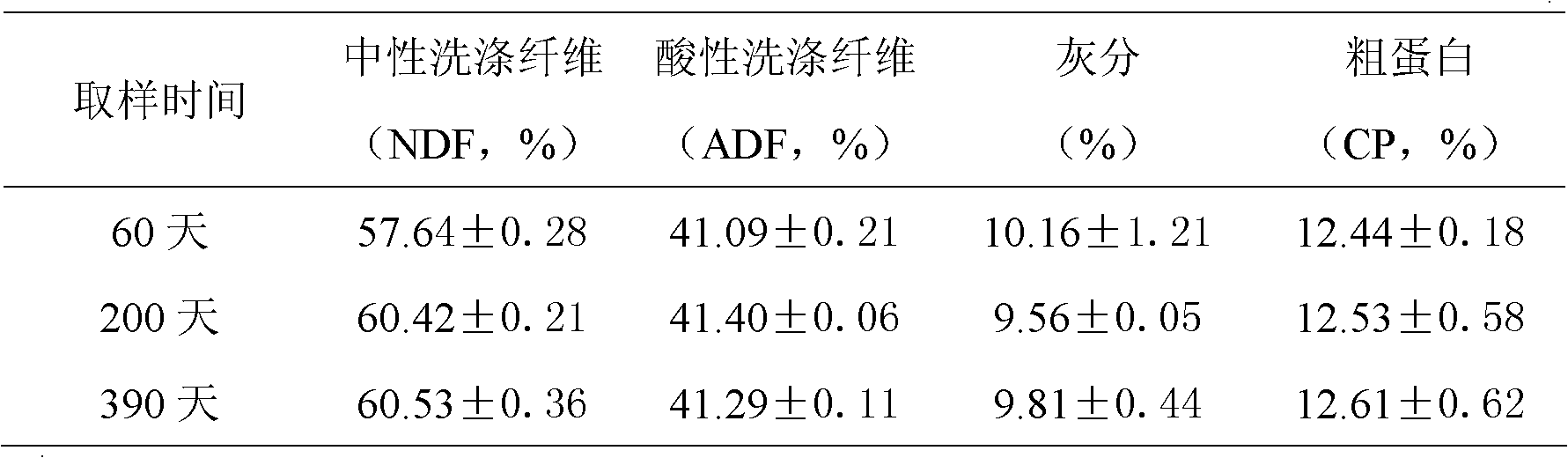

[0021] Get the silage of embodiment 1 gained in 30 days, 60 days, 90 days, 120 days, 150 days, 200 days, 300 days, 390 days, through sensory evaluation and laboratory analysis, show that the feed of preparation is high-quality silage, details as follows:

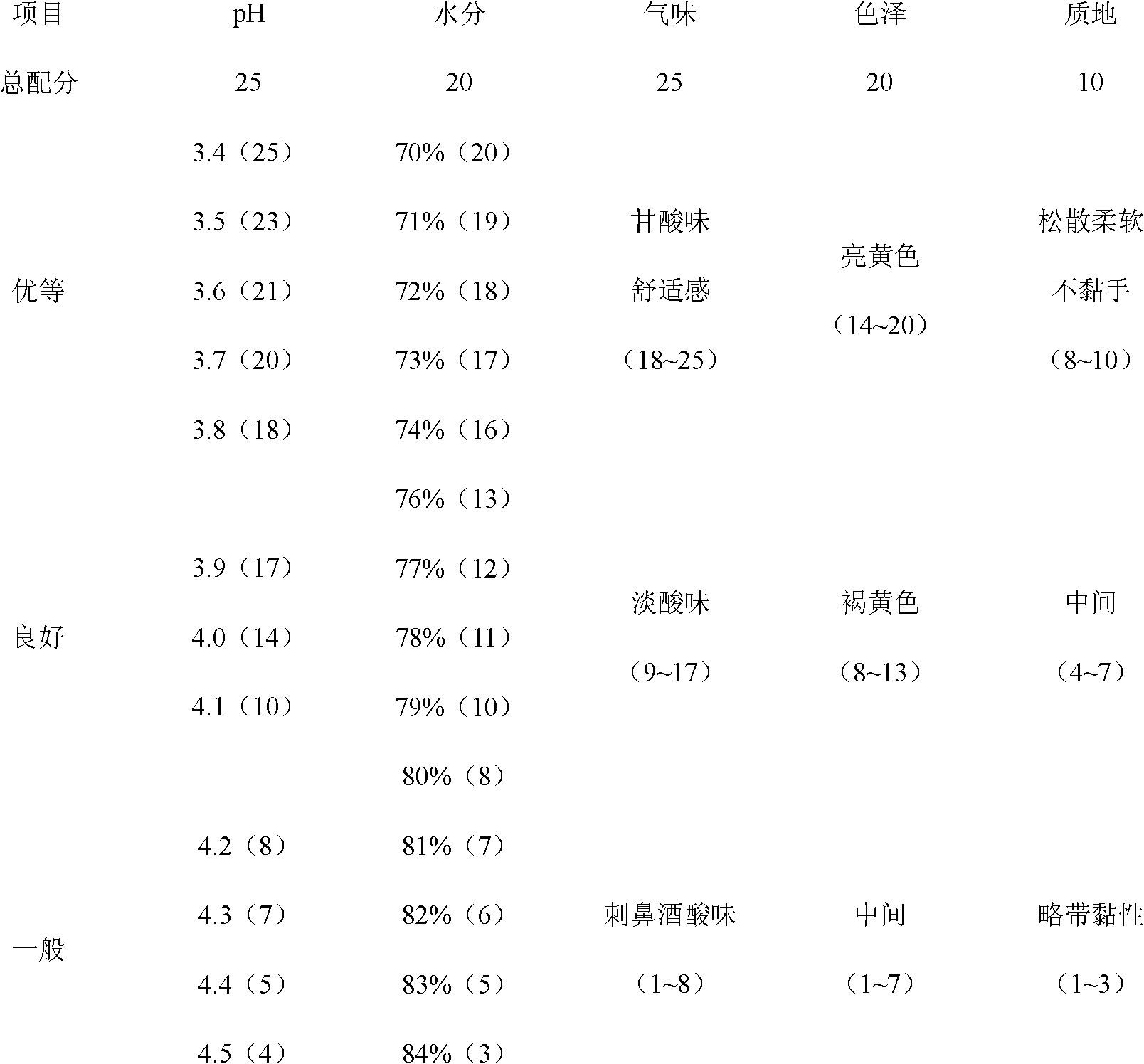

[0022] (1), sensory identification method is carried out according to table 1, table 2.

[0023] Table 1 Score table for sensory quality evaluation of silage

[0024]

[0025]

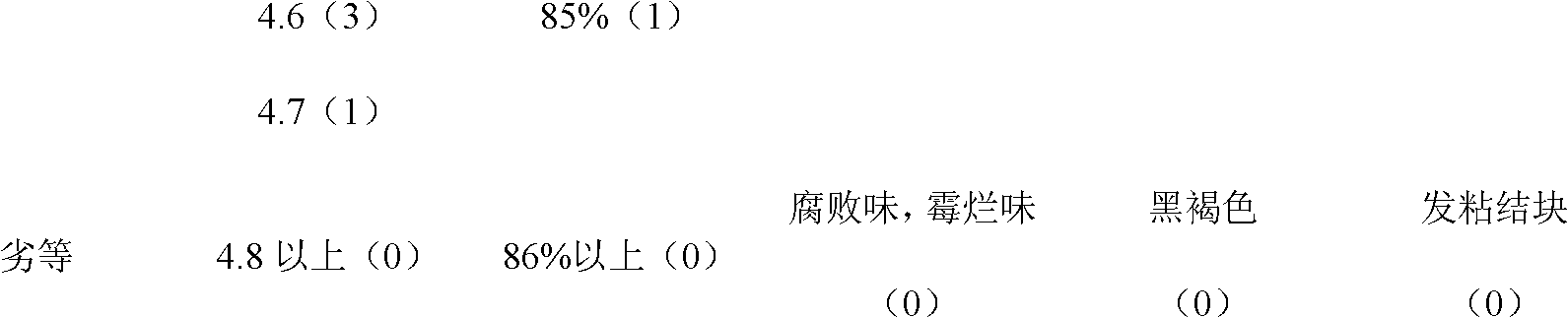

[0026] Table 2 Rating classification

[0027] Grade Excellent Good Fair Inferior

[0028] Score 100~76 75~51 50~26 Below 25

[0029] Samples were taken at 30 days, 60 days, 90 days, 120 days, 150 days, 200 days, 300 days, and 390 days. The measurement showed: pH 3.6-4.1, moisture 65%-66%, maintaining the fragrance of bamboo shoots and bringing comfort The wine smell is yellow, the texture is loose and not sticky, and there is no solid-liquid separation. The comprehensive score is between 83 and 92; the sensory evaluation is excellent.

[...

Embodiment 3

[0035] A total of 12 first-generation (F1) hybrid Simmental x local yellow cattle with similar body weight and body condition were selected and randomly divided into 2 treatments, 6 bulls in each treatment, which were the experimental group and the control group, respectively. The basal rations fed to the test group and the control group were the same, and the silage and rice straw obtained in Example 1 were fed respectively as roughage. The result shows: every beef cattle eats 10~15kg of the silage that embodiment 1 gains every day, increases feed intake, improves daily gain, increases breeding income than the beef cattle fed with rice straw; Specifically as follows:

[0036] 1. Materials and methods

[0037] 1. Experimental animals and experimental treatment

[0038] In this study, 12 12-month-old Simmental x local yellow cattle hybrid first generation (F1) bulls with similar body weight and body condition were selected. The randomized grouping experiment design was adopte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com