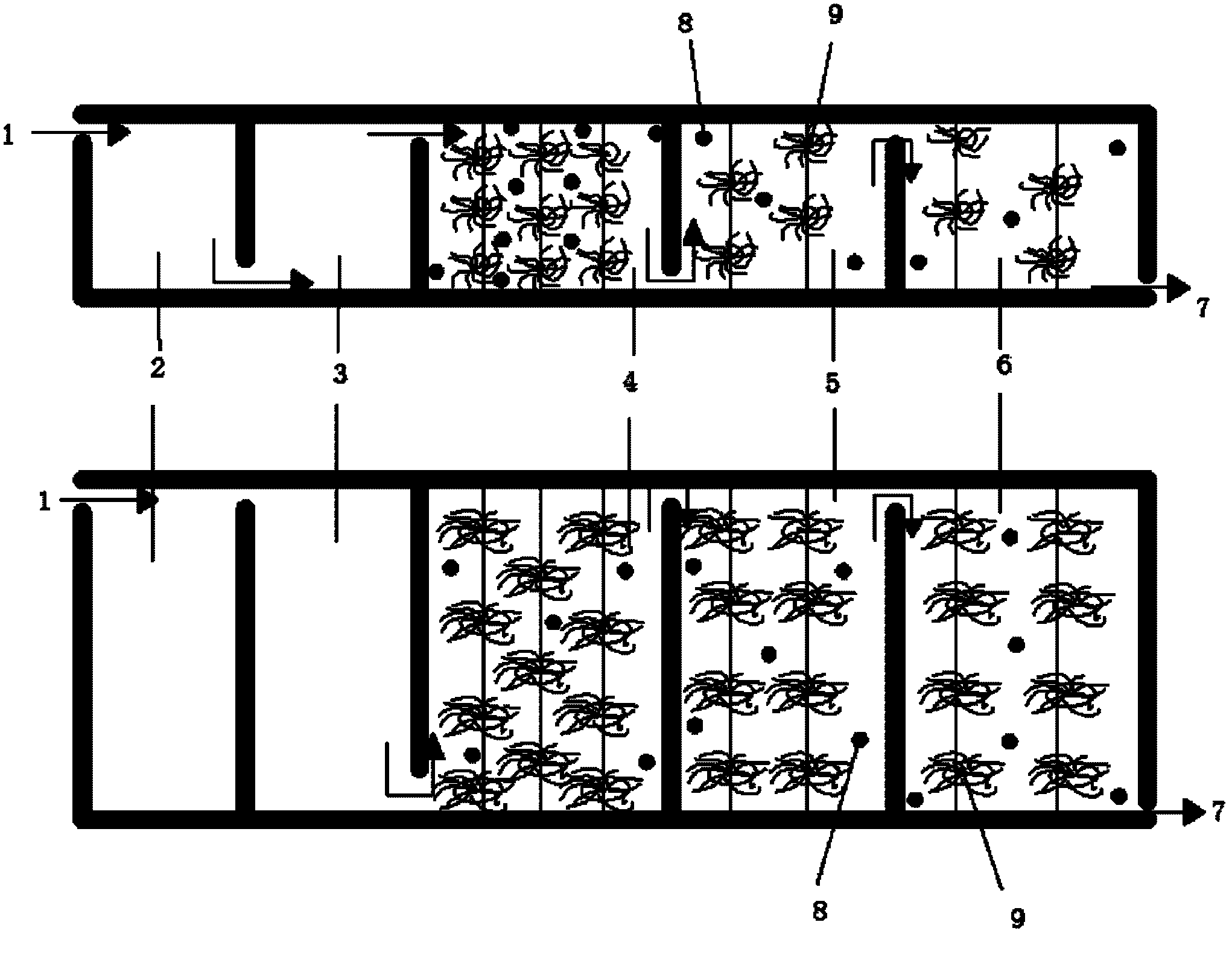

Method for treating trace pharmaceuticals and personal care products (PPCPs) in water through biological activation aeration process

A biological activation and aeration technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of low specific surface area and oxygen utilization rate of biofilm carrier, insufficient microbial biomass, etc. , to achieve the effect of small footprint, low price and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

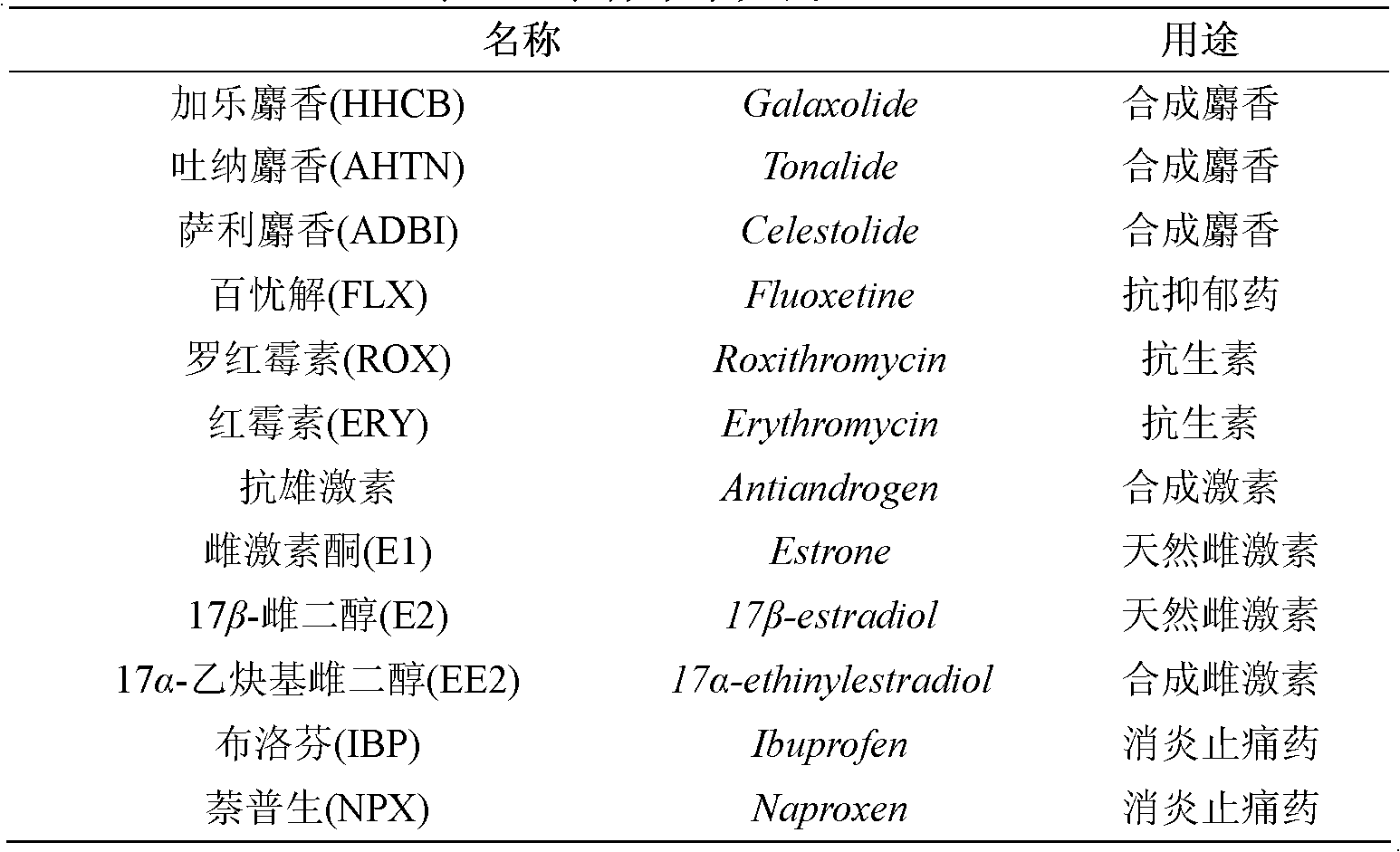

Method used

Image

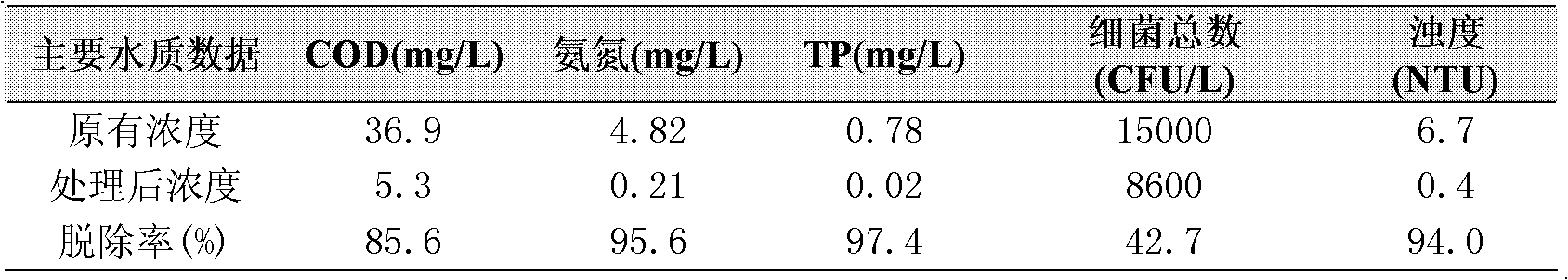

Examples

Embodiment 1

[0040] (1) Add bioactivator

[0041] In the first three days before the bioactivation aeration water treatment system is started, the bioactivator with a total concentration of 28mg / L is added to the primary aerobic tank 4 in the form of uniform spraying in water, once a day, and it is not necessary to add during normal operation. Daily input amount of bioactivator (M) According to empirical formula M=45-0.45×COD(g / m 3 )calculate. The biological activator Bio ActivationTM (abbreviated as BA, purchased from Duwei Science and Technology Environmental Protection Engineering Co., Ltd., Shunde District, Foshan City) selected in this embodiment is processed from natural organic waste, including enzyme preparations, trace elements, amino acids and polysaccharides, but not Water treatment chemicals containing microorganisms. Enzyme preparations account for 80% of the total, including 50% protease, 40% lipase and 10% cellulase. Trace elements account for 10% of the total, and trace ...

Embodiment 2

[0055] (1) Add bioactivator

[0056] In the first three days before the bioactivation aeration water treatment system is started, the bioactivator with a total concentration of 22mg / L is added to the primary aerobic tank 4 in the form of uniform spraying in water, once a day, and it is not necessary to add during normal operation. Daily input amount of bioactivator (M) according to empirical formula M=54-0.6×COD(g / m 3 )calculate. The bioactivator (purchased from Duwei Science and Technology Environmental Engineering Co., Ltd., Shunde District, Foshan City) consists of enzyme preparations, trace elements, amino acids and polysaccharides. Enzyme preparations account for 75% of the total, including 50% protease, 40% lipase and 10% cellulase. Trace elements account for 10% of the total, and trace elements are copper, zinc, manganese and cobalt. Amino acids and polysaccharides account for 15% of the total. The ratio of amino acids to polysaccharides is 2:3. Amino acids and polys...

Embodiment 3

[0070] (1) Add bioactivator

[0071] Three days before the bioactivation aeration water treatment system is started, add bioactivators with a total concentration of 45mg / L to the primary aerobic tank 4 in the form of uniform spraying in water, once a day, and do not need to be added during normal operation. Daily input amount of bioactivator (M) according to empirical formula M=50-0.28×COD(g / m 3 )calculate. The bioactivator (purchased from Duwei Science and Technology Environmental Engineering Co., Ltd., Shunde District, Foshan City) consists of enzyme preparations, trace elements, amino acids and polysaccharides. Enzyme preparations account for 80% of the total, of which protease 40%, lipase 40%, cellulase 20%; trace elements account for 10% of the total, trace elements include copper, zinc, manganese; amino acids and polysaccharides account for the total 10%, the ratio of amino acid to polysaccharide is 3:4, amino acid and polysaccharide come from food waste, amino acid is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com