Method for detecting and analyzing trivalent chromium and hexavalent chromium in water sample simultaneously on line

A technology of trivalent chromium and hexavalent chromium, which is applied in the direction of analyzing materials, material separation, measuring devices, etc., can solve the problems of human health injury, high toxicity, cumbersome steps, etc., to ensure sensitivity and accuracy, fast online measurement, The effect of saving analytical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

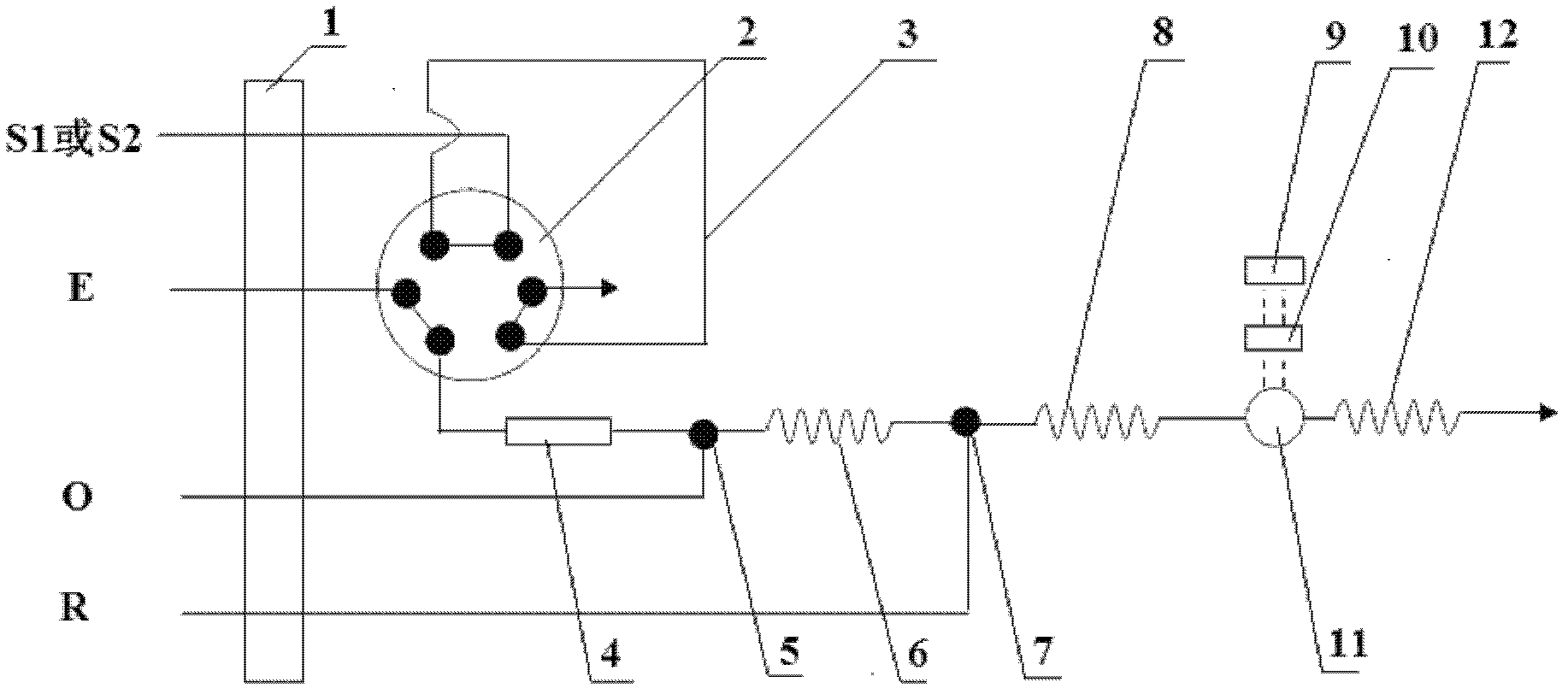

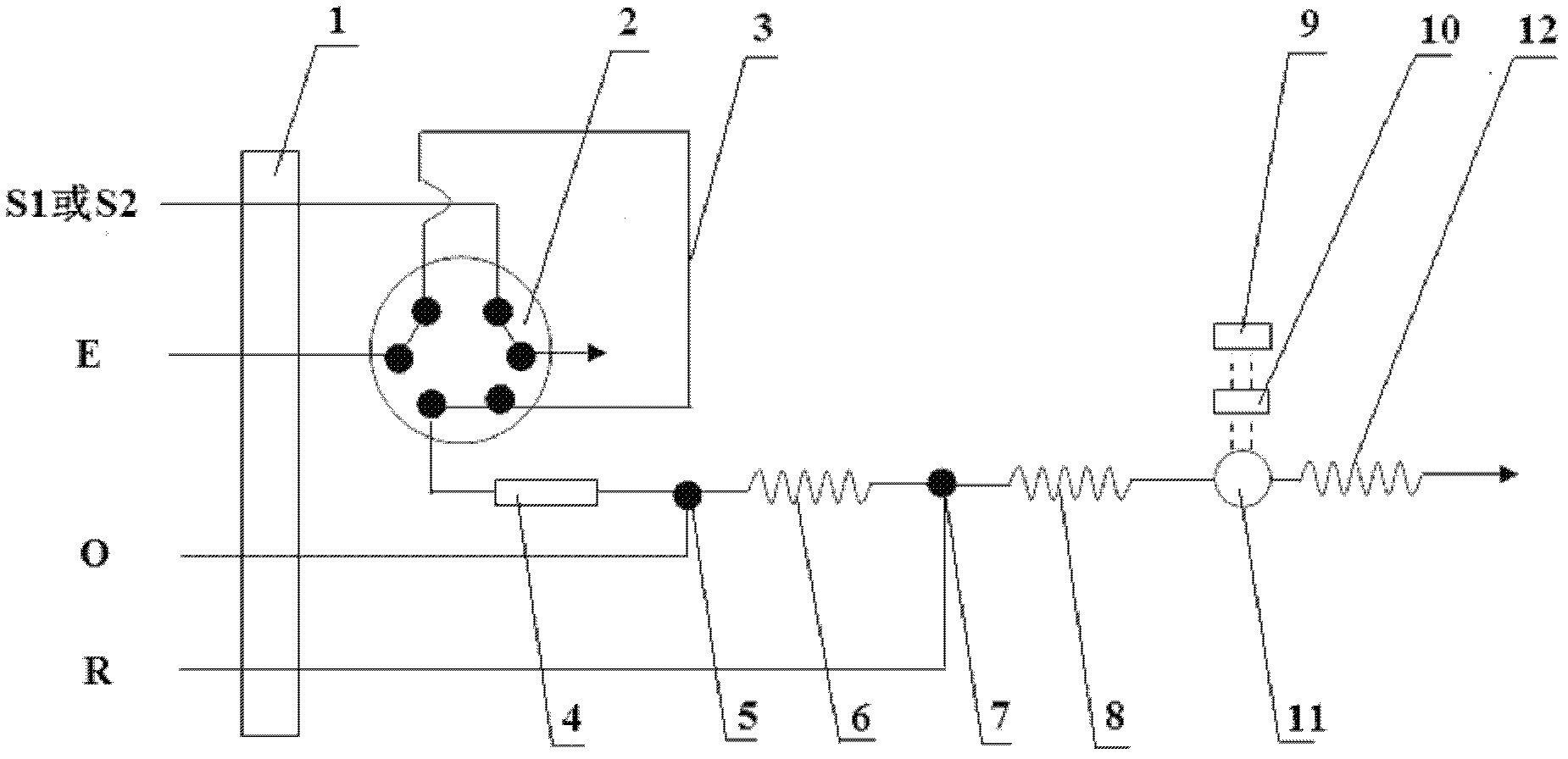

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment prepares carboxymethyl cross-linked starch adsorbent, and the process steps are as follows:

[0049] (1) Preparation of cross-linked starch

[0050] The mass ratio of starch and sodium chloride=10:1, the volume ratio of deionized water and epichlorohydrin=50:3, the sum of starch and sodium chloride mass: the sum of deionized water and epichlorohydrin volume= 40:53, the mass of starch and sodium chloride is measured in grams, and the volume of deionized water and epichlorohydrin is measured in milliliters;

[0051] Mix starch and sodium chloride at normal pressure and room temperature to form a mixed material, then add deionized water and epichlorohydrin to the mixed material and mix uniformly to form a slurry, and then add a 10% KOH aqueous solution Add the slurry and stir for 20 hours. After the stirring time expires, the cross-linked starch is obtained by filtration. The added amount of the KOH aqueous solution is: the volume ratio of the KOH a...

Embodiment 2

[0057] This embodiment prepares low-pressure cation exchange resin, and the process steps are as follows:

[0058] (1) Taking styrene and divinylbenzene as raw materials, taking benzoyl peroxide as a catalyst, the quality of styrene: the quality of divinylbenzene: the quality=600:60:1 of benzoyl peroxide; , divinylbenzene and benzoyl peroxide are put into a reaction vessel, and the polymerization reaction is carried out at normal pressure and 90° C. to generate styrene-divinylbenzene spherical copolymer beads, and the reaction time is 15 hours;

[0059] (2) the styrene-divinylbenzene spherical copolymer beads prepared by step (1) are placed in a reaction vessel, and concentrated H 2 SO 4 , sulfonated at normal pressure and 95°C for 30min under stirring to obtain a low-pressure cation exchange resin, concentrated H 2 SO 4 The amount of addition is: the quality of the beads: concentrated H 2 SO 4 The volume=1:4, the mass of styrene-divinylbenzene spherical copolymer beads i...

Embodiment 3

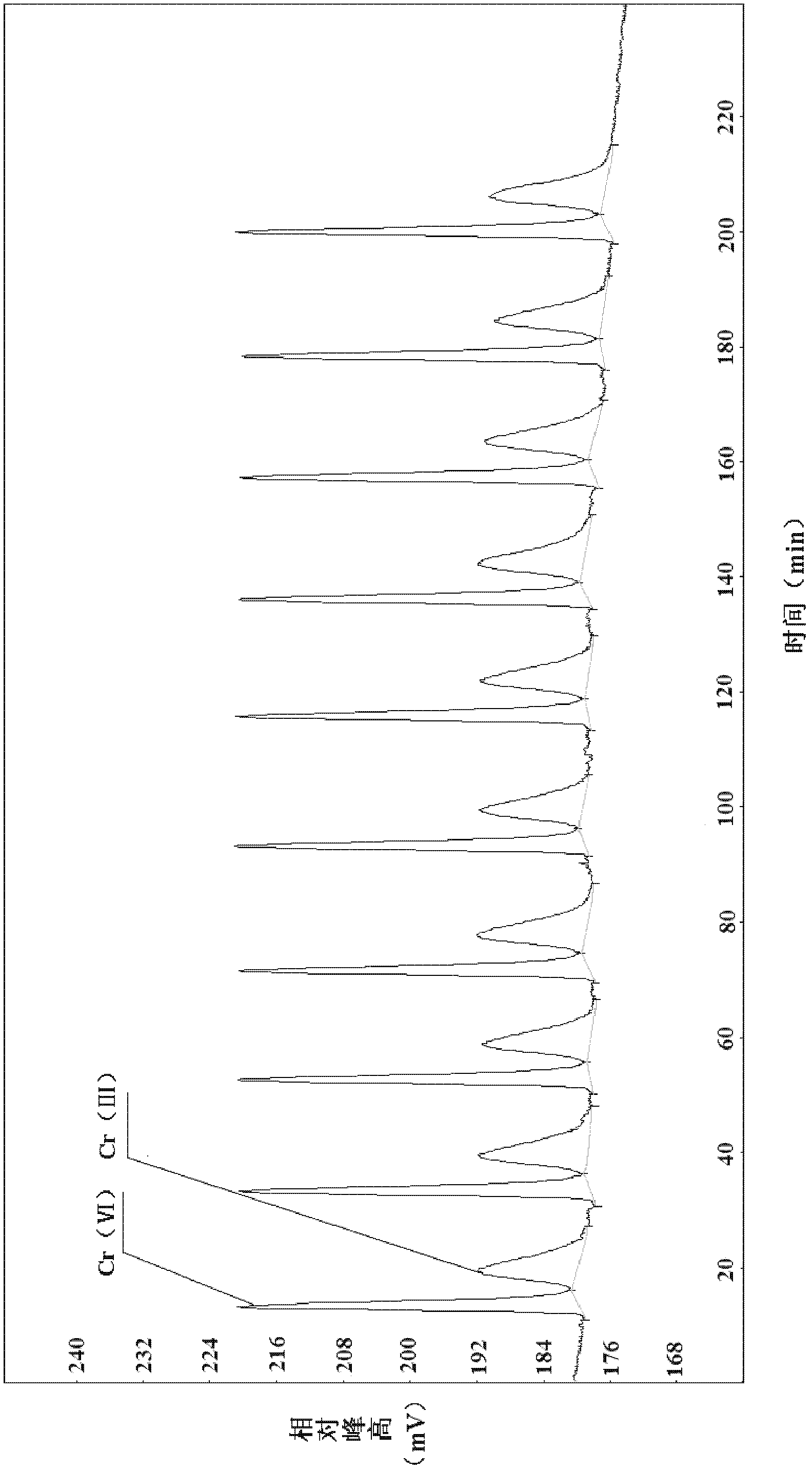

[0061] In this embodiment, the standard sample is tested to investigate the precision of the method of the present invention. The steps are as follows:

[0062] 1. Preparation of standard samples

[0063] (1) Prepare 100mg / L Cr(VI) standard stock solution: weigh 0.0270g K 2 Cr 2 o 7 Dissolve in deionized water, transfer to a 100mL volumetric flask, shake well, dilute to volume, and set aside.

[0064] (2) Prepare 1000mg / L Cr(III) standard stock solution: weigh 0.7692g chromium nitrate (Cr(NO 3 ) 3 9H 2 O) Dissolve in deionized water, transfer to a 100mL volumetric flask, shake well, dilute to volume, and set aside.

[0065] (3) Prepare a mixed standard sample with a Cr(VI) concentration of 50 μg / L and a Cr(III) concentration of 100 μg / L: Measure 0.050 mL of 100 mg / LCr(VI) standard stock solution and 1000 mg / L Cr(III) standard 0.010mL of the stock solution was transferred into a 100mL volumetric flask, shaken well, and made to volume.

[0066] 2. Preparation of oxidizi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter φ | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com