Method for preparing high-quality graphene in large scale by intercalation stripping of graphite by chemical method

A technology of graphene and graphite, which is applied in the field of graphene preparation, can solve the problems of poor stability control, poor quality of graphene, high cost, etc., and achieve the effect of thorough stripping, easy processing, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

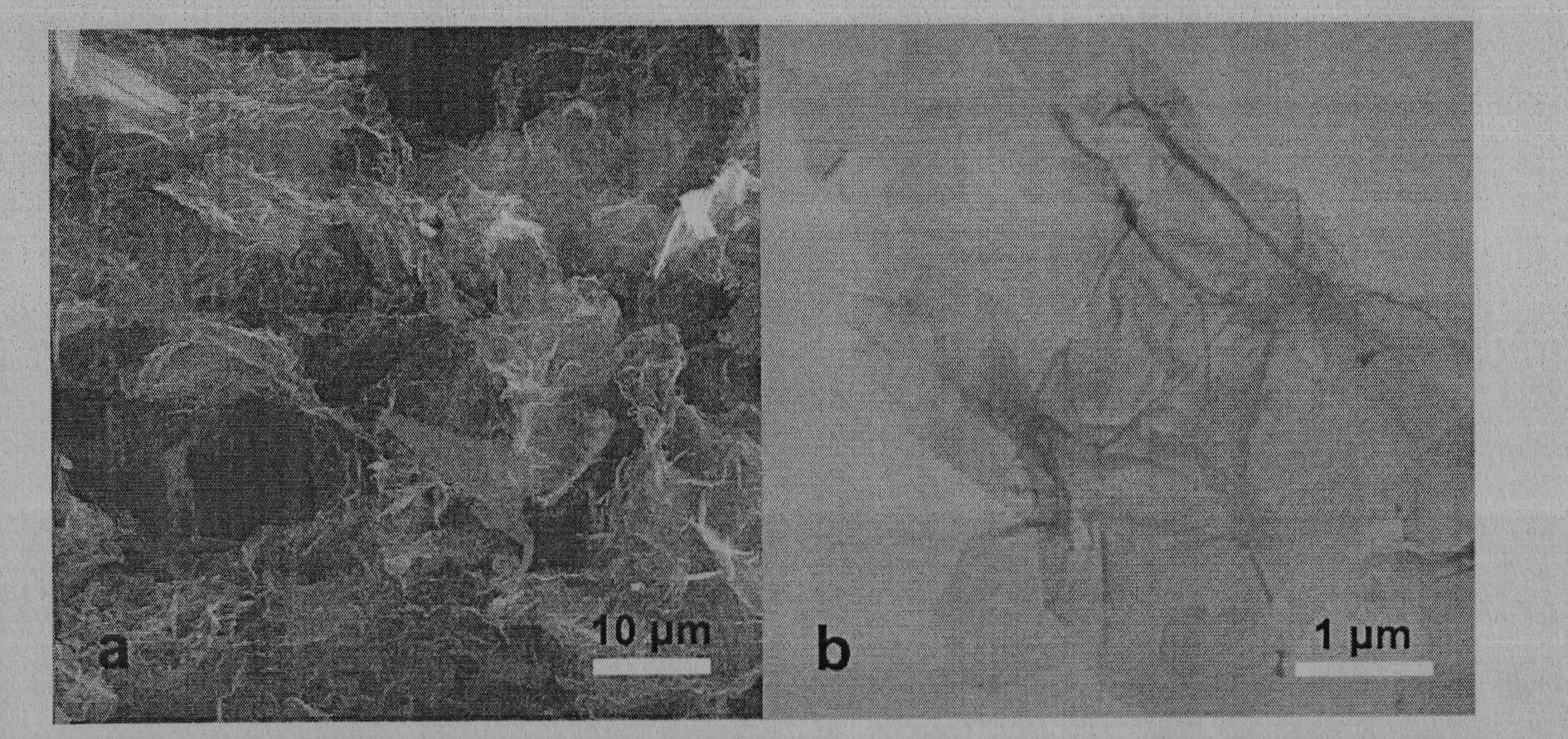

[0037] Add 10g of graphite powder or flake graphite (50 mesh to 1000 mesh) or expanded graphite into 200mL to 1L of chlorosulfonic acid mixed acid, the ratio of mixed acid is: chlorosulfonic acid / concentrated sulfuric acid / perchloric acid=8 / 1~4 / 1~3, Stir evenly and seal well. After ultrasonic treatment for 30 minutes, soak statically or stir magnetically for 2-24 hours. Then, a 30% aqueous hydrogen peroxide solution was slowly added dropwise to the mixture while stirring. After adding 100-500mL of hydrogen peroxide, the above mixture will expand rapidly and turn into a black viscous colloid, like black wet soil. The dropping process is dangerous, pay attention to the dropping speed. The resulting gel was then washed to neutral with deionized water. Then the obtained graphene dispersion can be better dispersed by ultrasonic treatment, so that the agglomerated graphene in the cleaning process can be separated into a fluffy floc, and the ultrasonic treatment can be done for 3...

Embodiment 2

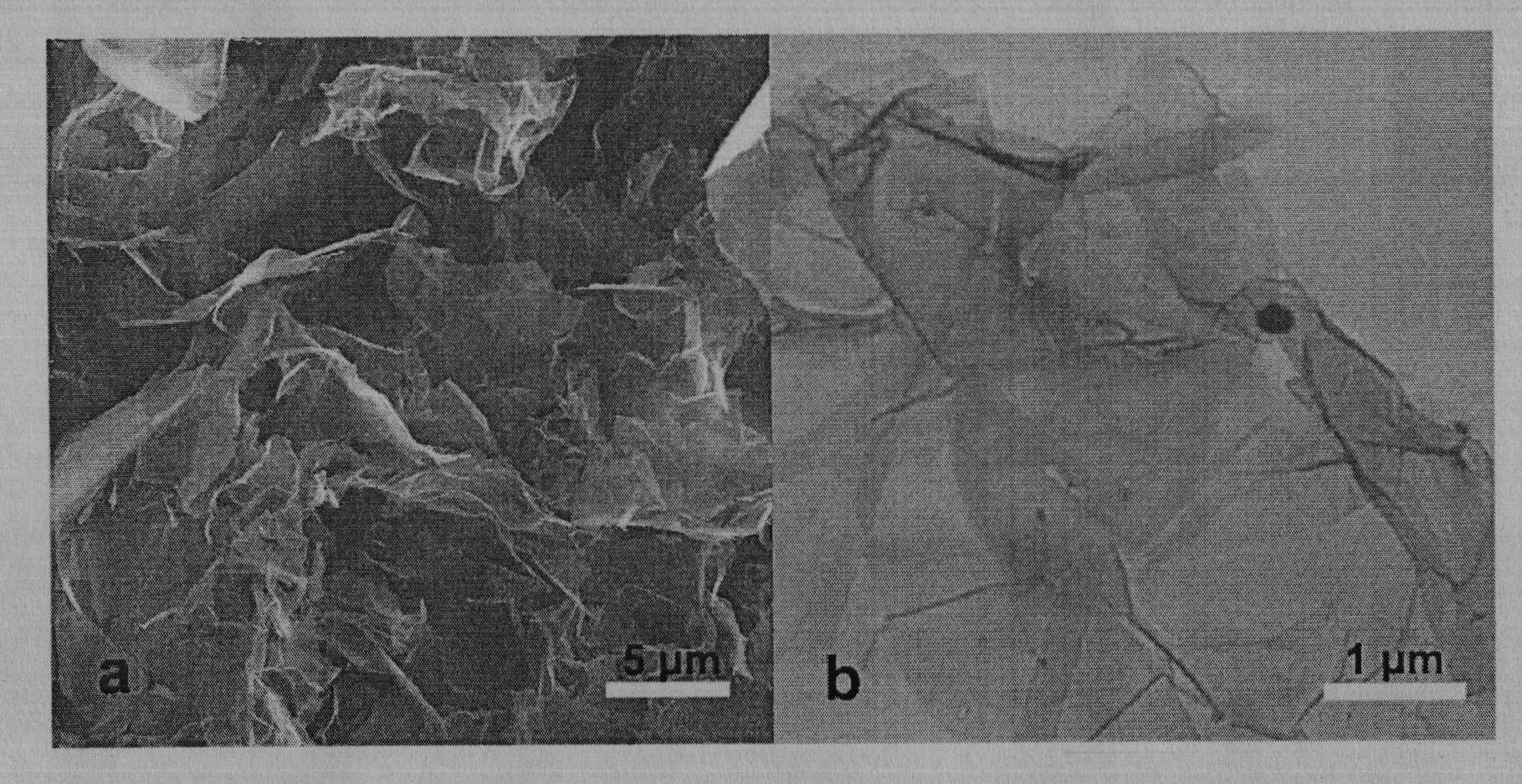

[0040] The experimental method is the same as in Example 1, except that after obtaining the black gel, it is dropped into 500-1000ml of polar organic reagents, and these polar organic reagents can be: methyl formamide (DMF), N-methylpyrrolidone ( NMP), dimethyl sulfoxide (DMSO), etc. Ultrasonic treatment of these organic dispersions of graphene can reduce the agglomeration of graphene and obtain more single-layer graphene. Then wash with water to pH 6-7. The obtained graphene surface will have these small molecule organic solvents adsorbed on the surface, which is conducive to its dispersion in some solvents.

Embodiment 3

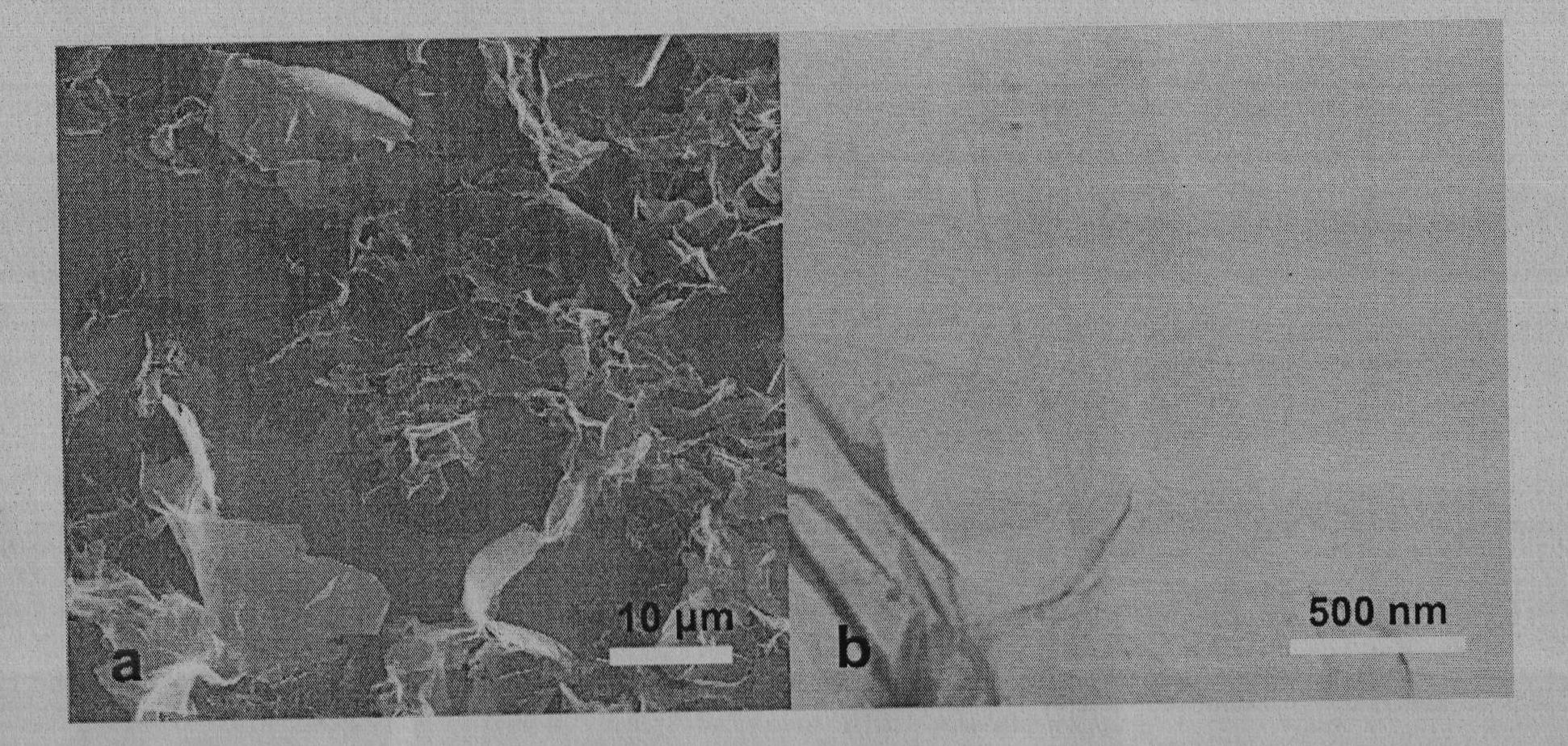

[0042] Experimental method is the same as embodiment 1, just when soaking, some surfactants and some polymers are added in the acid solution, these surfactants and polymers have: sodium dodecylsulfonate, hexadecylbenzenesulfonate Sodium tritonate, triton X-100, polystyrene, sodium polystyrene sulfonate, polyaniline, sodium polyaminobenzene sulfonate, polypyrrole, polythiophene, PEDOT, etc. Adding some polymers can reduce the re-aggregation of graphene during the exfoliation process, and can also improve its dispersion. The addition of some polymers directly completes the compounding with the polymer during the exfoliation process of graphene, which can be used as a This graphene composite material is directly applied in some fields.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com