Preparation method of graphene loaded ordered polyaniline nanorod array electrode material

A technology of nanorod arrays and electrode materials, applied in circuits, capacitors, electrical components, etc., can solve the problems of polyaniline chemical structure damage, complex process, and affecting the overall performance of composite materials, and achieve excellent electrochemical performance. The effect of simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

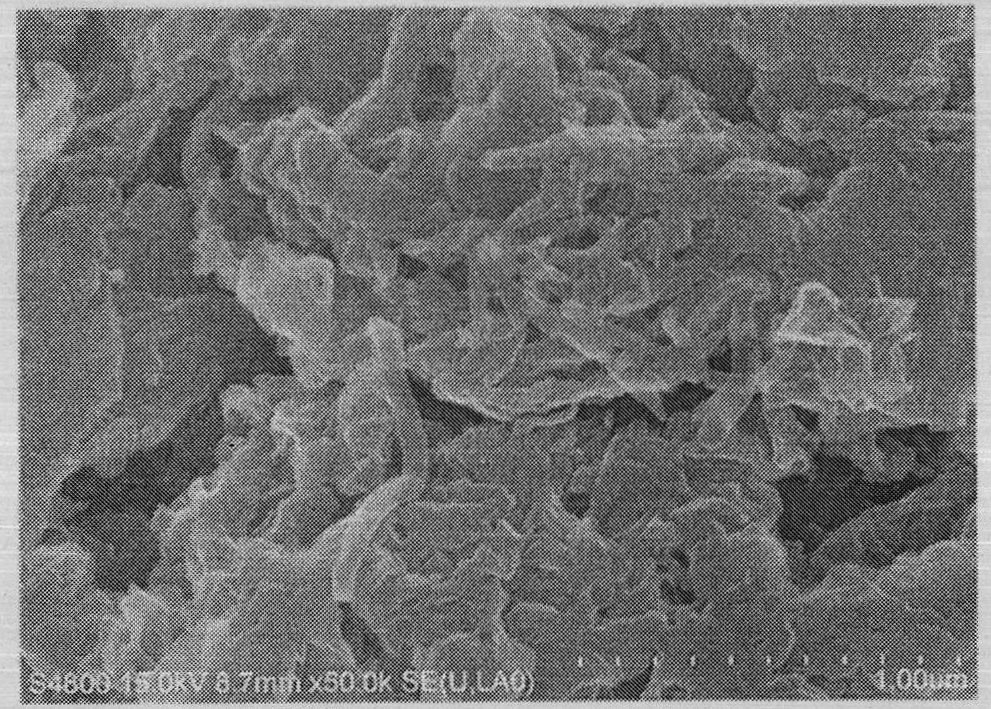

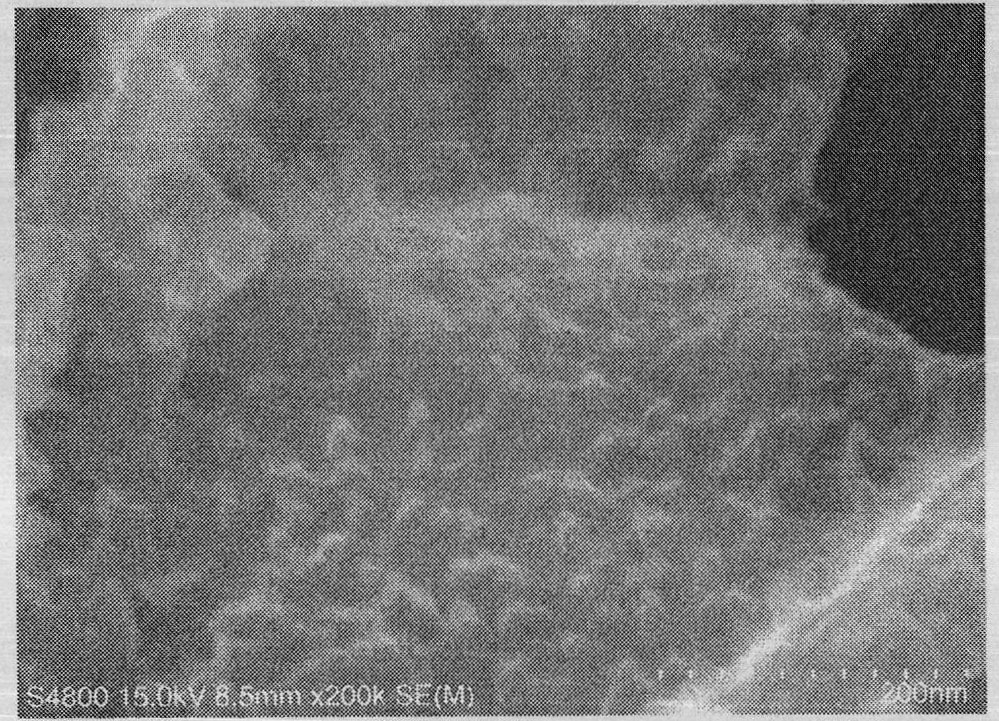

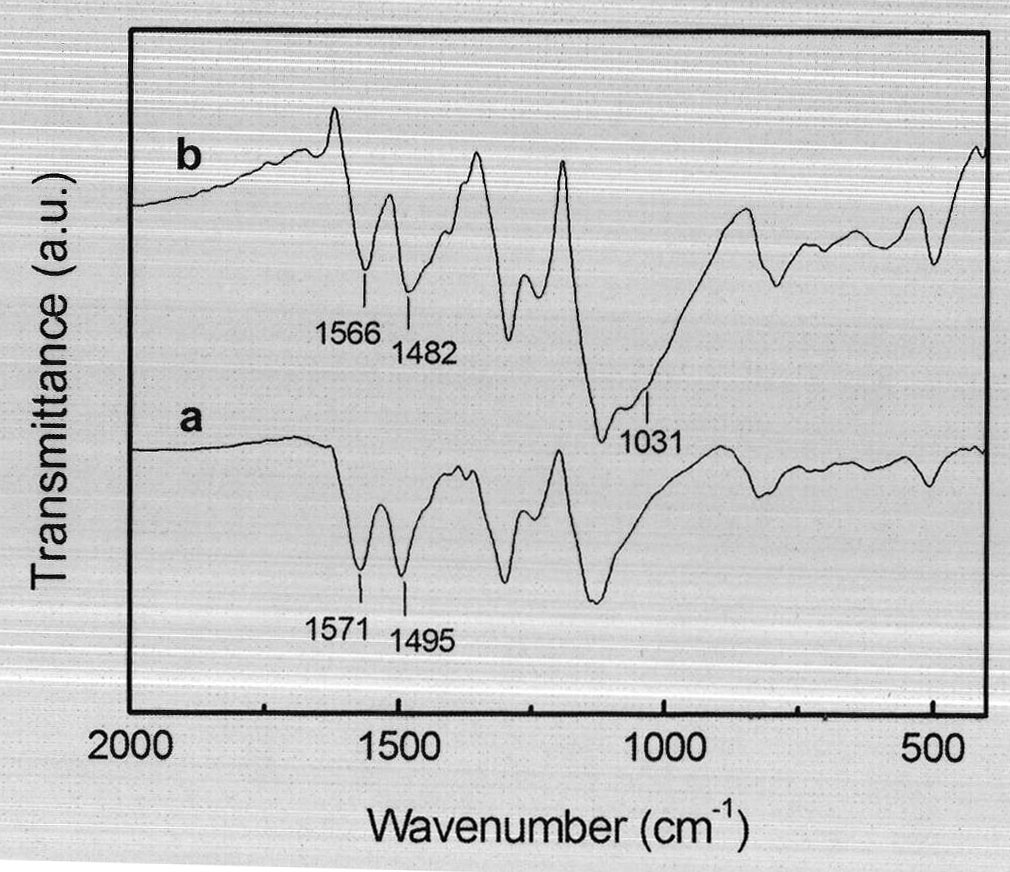

[0032] (1) Sulfonated graphene is carried out according to the following steps: put graphite oxide into an aqueous solution of pH = 9 to 10, and after ultrasonic dispersion for 2 hours, make it fully peeled off; pre-reduce graphite oxide with sodium borohydride, and control boron Sodium hydride: the mass ratio of graphite oxide is 3: 1, reacts 1 hour at 80 ℃, to remove most of oxygen-containing groups in graphite oxide, obtains the graphite oxide of part reduction; Use p-aminobenzenesulfonic acid diazonium salt and The above-mentioned partly reduced graphite oxide was reacted in an ice-water bath for 3 hours, and the mass ratio of the controlled p-aminobenzenesulfonic acid diazonium salt: partly reduced graphite oxide was 1.3: 1 to introduce sulfonic acid groups; the above-mentioned sulfonated product was React with hydrazine hydrate at 100°C for 24 hours, fully reduce to remove residual oxygen-containing groups, wash with deionized water until neutral, and dry to obtain sulfon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com