ZnWO4-coated aluminum borate whisker-reinforced aluminum matrix composite and preparation method thereof

A technology of aluminum borate whiskers and reinforced aluminum matrix, which is applied in the field of aluminum matrix composite materials, can solve the problems of poor interface wettability, easy delamination, and reduced mechanical properties, so as to improve the mechanical properties of materials, prevent interface reactions, and yield strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

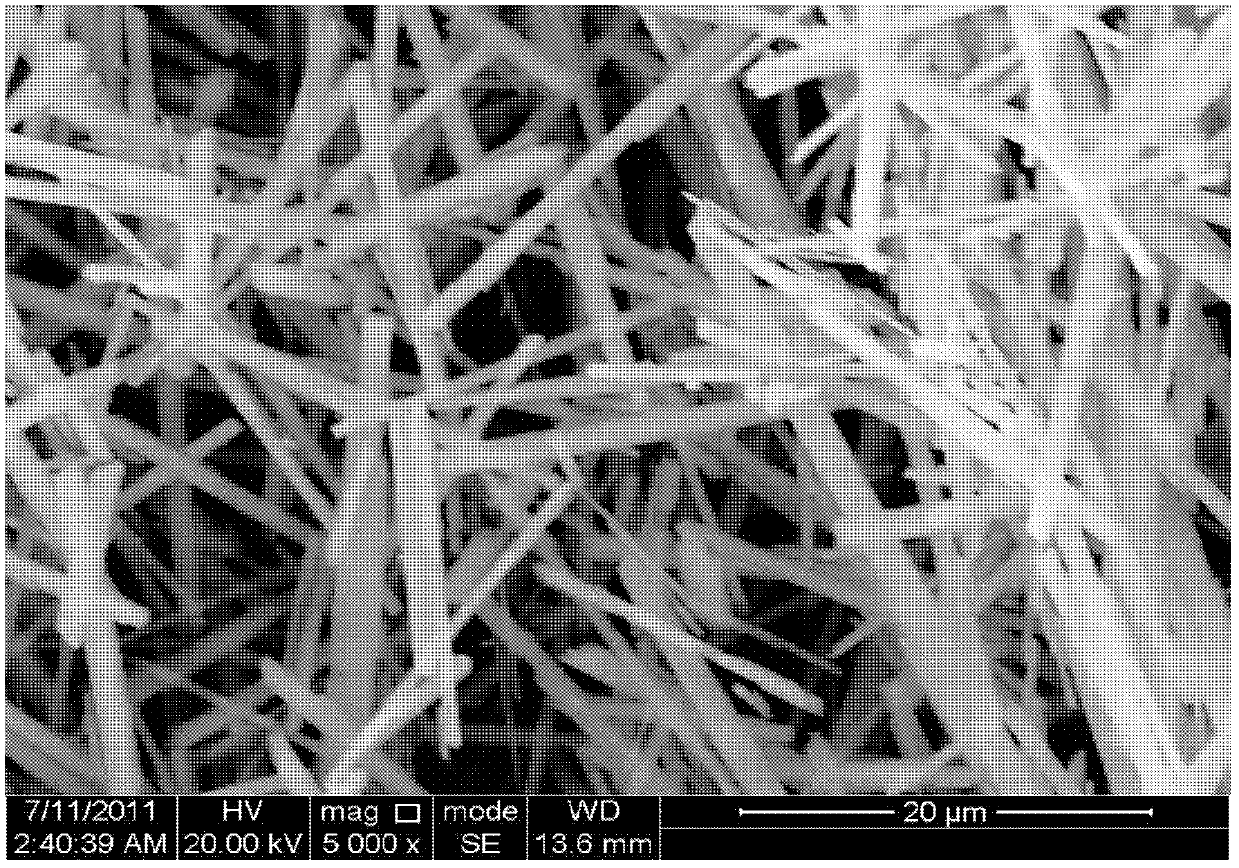

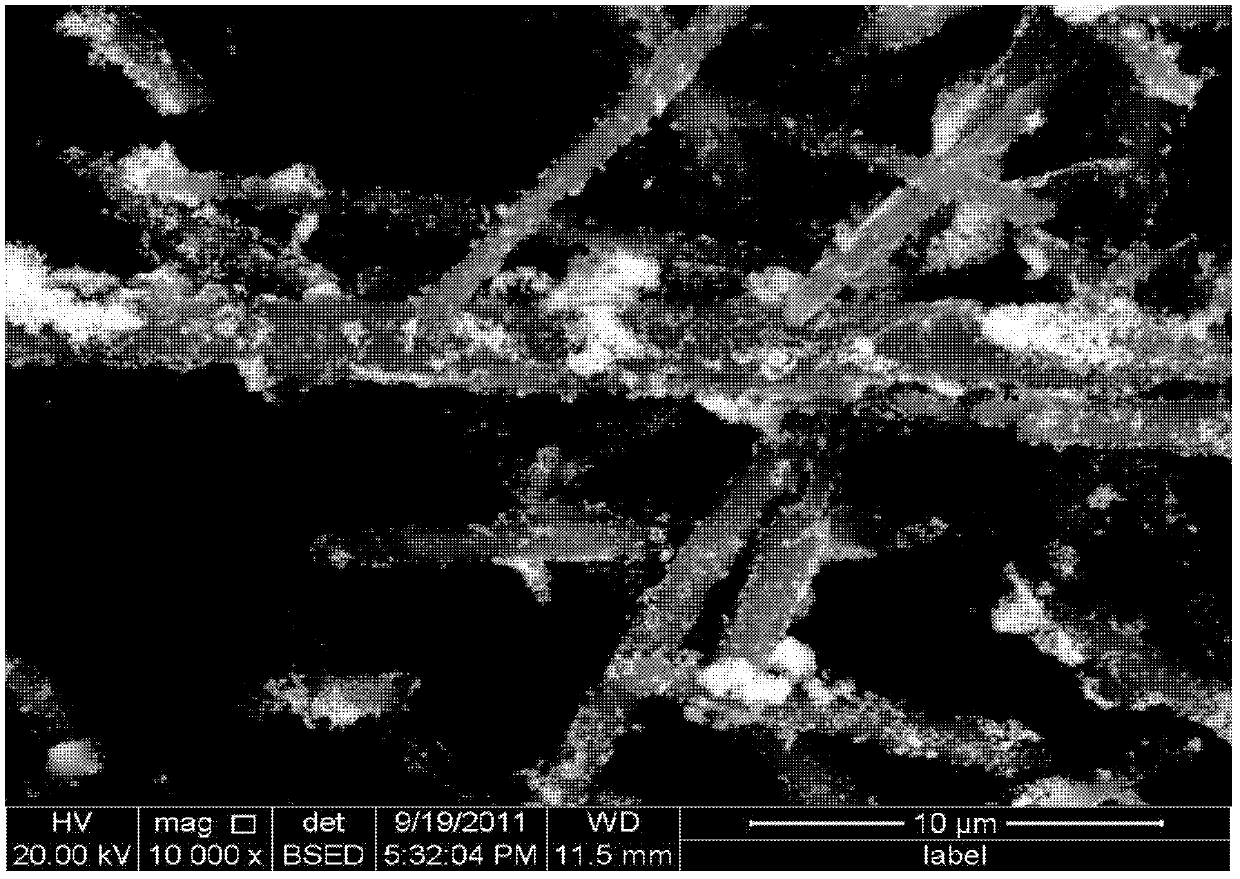

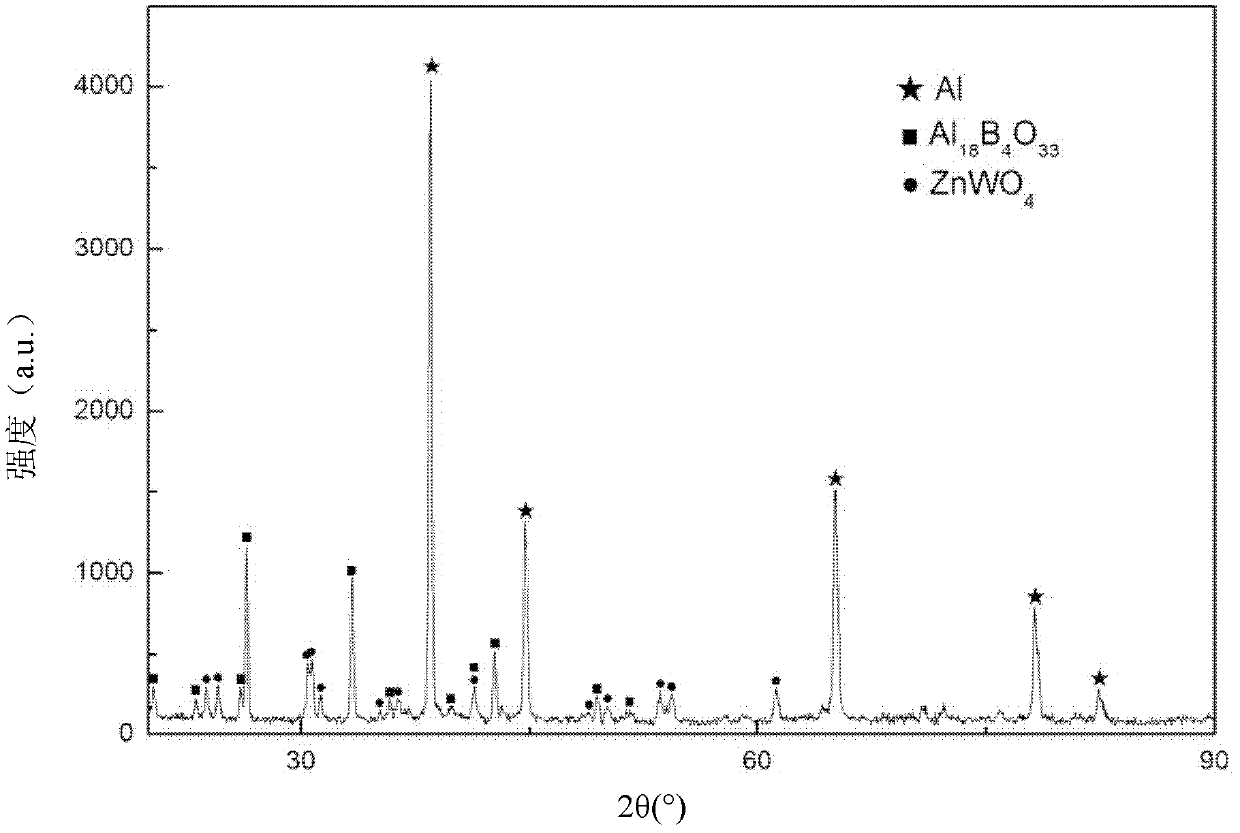

[0014] Specific embodiment one: ZnWO in this embodiment 4 Coated aluminum borate whisker reinforced aluminum matrix composite material made of zinc tungstate (ZnWO 4 ), aluminum borate whiskers and aluminum matrix, of which aluminum borate whiskers account for ZnWO 4 Coated aluminum borate whisker reinforced aluminum matrix composite material 10%-40% of the total integral number, ZnWO 4 The mass of aluminum borate whiskers is 2% to 100%.

specific Embodiment approach 2

[0015] Specific embodiment two: this embodiment is different from the specific embodiment one is: ZnWO 4 The mass of aluminum borate whiskers is 10% to 50%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: This embodiment is different from the specific embodiment 1: ZnWO 4 The mass of is 20% of the mass of aluminum borate whiskers. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com