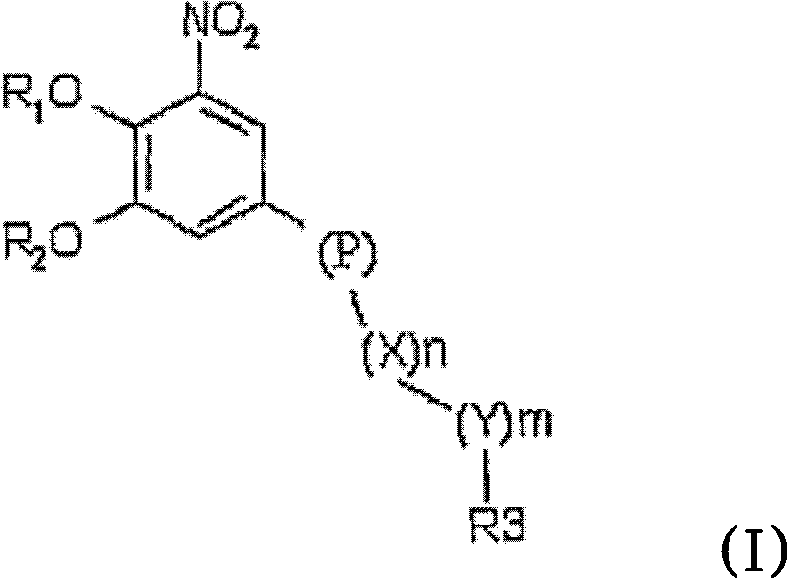

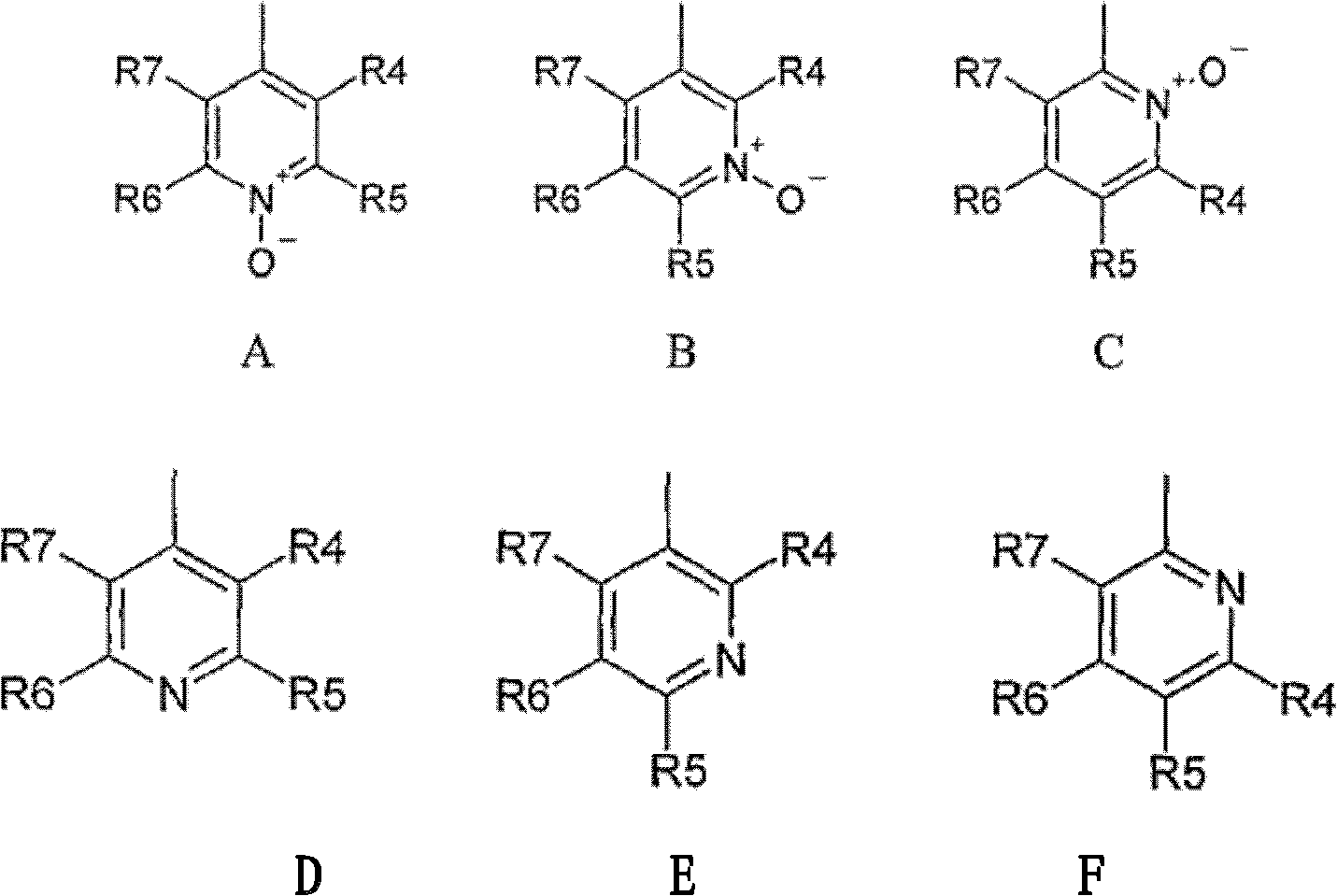

Pharmaceutical formulations comprising nitrocatechol derivatives and methods of making the same

The technology of a pharmaceutical preparation and nitrobenzene is applied in the field of pharmaceutical preparations including nitrocatechol derivatives and their preparation, and can solve the problems of sensitivity, low bulk density, lack of stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

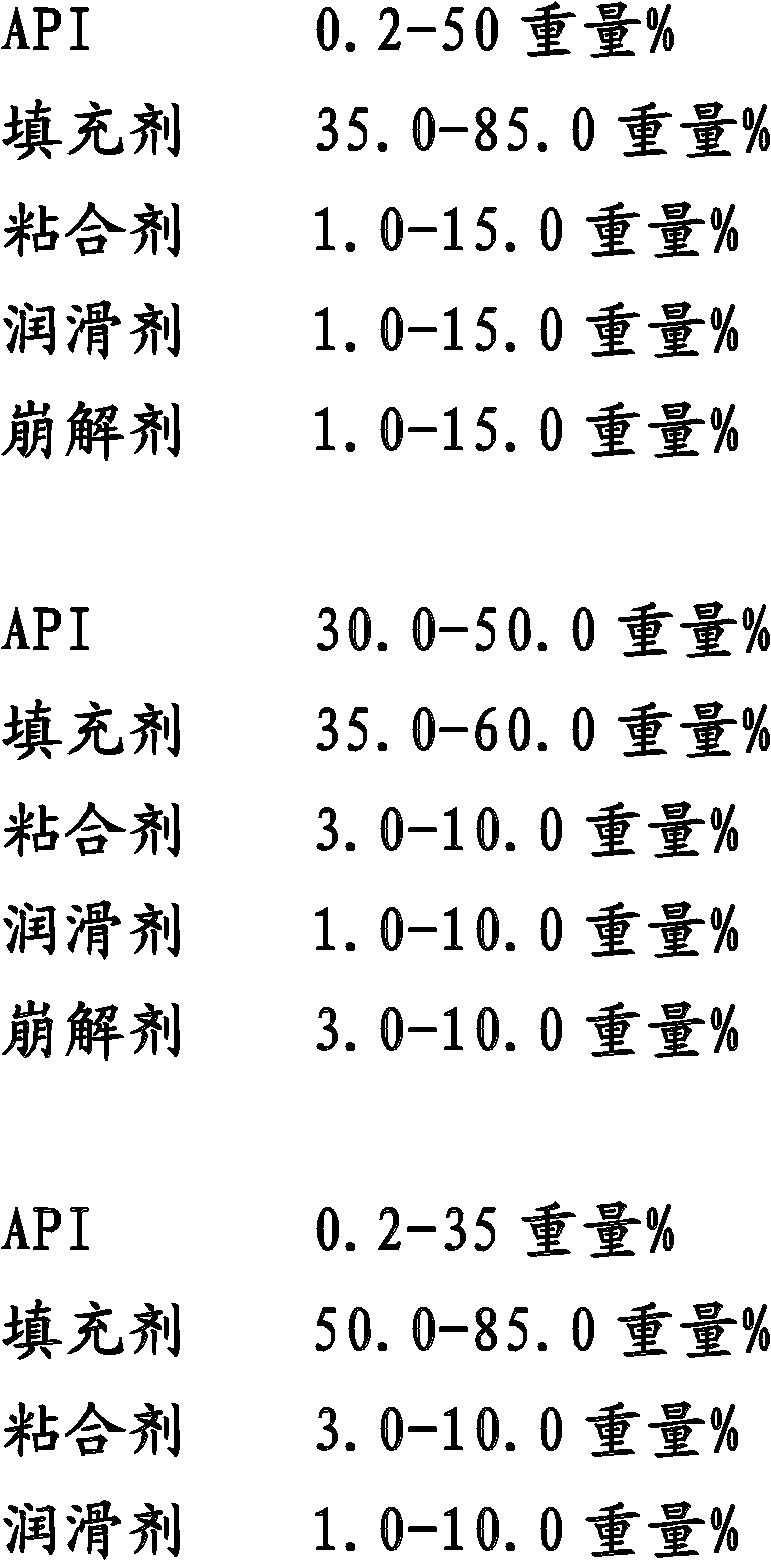

Method used

Image

Examples

Embodiment 1

[0100] Four low-dose capsules were prepared in pilot batches by first mixing API, starch, and lactose in the amounts shown in Table 1 below (Batches A-D). The API used in these examples is 2,5-dichloro-3-(5-(3,4-dihydroxy-5-nitrophenyl)-1,2,4-oxadiazol-3-yl )-4,6-lutidine 1-oxide. Purified water was then added to each mixture, and the mixture was granulated by mixing.

[0101] The granules were then dried using a fluidized bed dryer until the granules had a loss on drying value of less than 6%. The dried granules were sieved and mixed with the remaining ingredients described in Table 1. This formulation was used to fill gelatin capsules using an InCAP HS capsule filling machine.

[0102] The bulk and tap densities of the granules and final compositions were evaluated using the methods described above. Mobility / flow rate was also evaluated by testing the flow rate through the orifice described in USP 31, Volume 1, Test , USP Regulations, 2008. Flowability can be measured a...

Embodiment 2

[0113]Four high-dose capsules were prepared on a laboratory scale by first mixing the API, starch, and lactose in the amounts shown in Table 1 below in a V-blender (batches E-H). The API used in these examples is 2,5-dichloro-3-(5-(3,4-dihydroxy-5-nitrophenyl)-1,2,4-oxadiazol-3-yl )-4,6-lutidine 1-oxide. Purified water was added to each mixture and mixed by hand. The wet mass thus obtained is then granulated in a vibrating granulator laboratory.

[0114] The granules were then dried in a box dryer until the loss on drying of the granules was below 6%. The dried granules are sieved. The granules were then mixed with the remaining ingredients described in Table 1 in a V-blender. This formulation was used to fill gelatin capsules using an InCAP HS capsule filling machine.

[0115] Each of batches E-H were evaluated as described in Example 1 above and the results are presented in Table 3 below. All batches exhibited good granule and capsule properties.

[0116] Table 1: B...

Embodiment 3

[0124] All batches of Examples 1 and 2 were subjected to accelerated studies to determine their stability. Each of the eight batches was stored for 15 days at room temperature and under stress conditions (70°C, no relative humidity control). All batches were tested for impurity content at both storage conditions and the results are presented in Tables 4 and 5. Impurity values were obtained using the HPLC method with a limit of quantification of less than 0.05%.

[0125] The API used in these batches contained approximately 3% impurities (including Impurity 8) prior to formulation.

[0126] Table 4: Stability test results for batches A-D

[0127]

[0128] RT - room temperature

[0129] SC-stress condition

[0130] NP - not present (below detection limit)

[0131] Table 5: Stability test results for batches E-H

[0132]

[0133] RT - room temperature

[0134] SC-stress condition

[0135] NP - not present (below detection limit)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com