Clodinafop-propargyl emulsion in water and preparation method thereof

A technology of clodinafop-propargyl and water-emulsion, which is applied in the field of 8% clodinafop-propargyl-water emulsion, can solve the problems of environmental hazards and high production investment costs, and achieve the effects of reduced production costs, simple processing methods, and high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

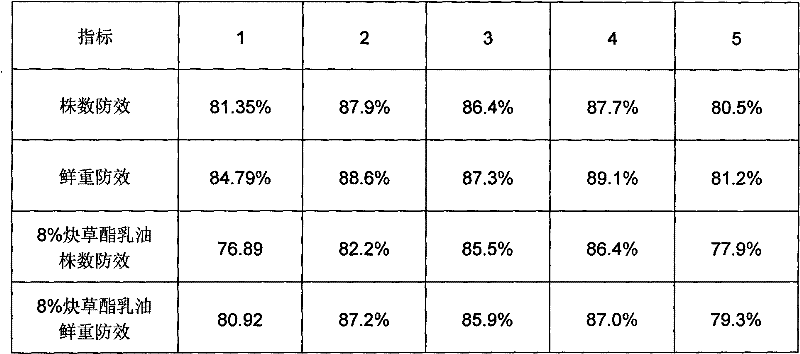

Examples

Embodiment 1

[0025] An aqueous emulsion containing clodinafop-propargyl 8%, clodinafop-propargyl 2%, xylene 20%, calcium dodecylbenzenesulfonate 5%, AEO-9 5%, hydrochloric acid 0.1%, ethylene glycol 5%, 1% of guar gum, 0.1% of simethicone oil, and the balance is water, all of which are weight ratios.

[0026] Dissolve 0.1% hydrochloric acid, 5% ethylene glycol and 1% guar gum in water to form a water phase; dissolve 8% clodinafop-propargyl and 2% cloclodin-propargyl in an organic solvent, add dodecane Calcium phenyl sulfonate 5%, nonylphenol polyoxyethylene ether (AEO-9) 5%, simethicone 0.1% form an oil phase; the oil phase and the water phase are mixed in an emulsification tank at 100 rpm Stir at a rotating speed for 30 minutes to obtain 8% clodinafop-propargyl emulsion in water.

Embodiment 2

[0028] A water emulsion containing clodinafop-propargyl 8%, clodinafop-propargyl 2%, xylene 10%, mixed benzene 10%, calcium dodecylbenzenesulfonate 5%, AEO-9 5%, hydrochloric acid 0.3%, ethyl alcohol 5% of diol, 1% of carboxymethyl starch, 0.1% of simethicone, and the balance is water, all of which are in weight ratio.

[0029] Dissolve 0.3% hydrochloric acid, 5% ethylene glycol, and 1% carboxymethyl starch in water to form a water phase; dissolve 8% clodinafop-propargyl and 2% clodinafop-propargyl in an organic solvent, add dodecane Calcium phenylsulfonate 5%, AEO-95%, and dimethyl silicone oil 0.1% form an oil phase; mix the oil phase and water phase in an emulsification kettle, and stir at 100 rpm for 30 minutes to obtain 8% alkyne Grass ester aqueous emulsion.

Embodiment 3

[0031] A water emulsion containing clodinafop-propargyl 8%, cloclodin-propargyl 2%, xylene 10%, cyclohexanone 10%, calcium dodecylbenzenesulfonate 5%, Tween-20 5%, hydrochloric acid 0.2% , 5% ethylene glycol, 1% carboxymethyl starch, 0.1% simethicone, and the balance is water, all of which are weight ratios.

[0032] Dissolve 0.3% hydrochloric acid, 5% ethylene glycol, and 1% carboxymethyl starch in water to form a water phase; dissolve 8% clodinafop-propargyl and 2% clodinafop-propargyl in an organic solvent, add dodecane 5% calcium phenylsulfonate, AEO-95%, and 0.1% dimethyl silicone oil form an oil phase; mix the oil phase and water phase in an emulsification kettle, and stir at 150 rpm for 30 minutes to obtain 8% alkyne Grass ester aqueous emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com