Method for preparing light olefin by adopting biolipid

A technology of bio-oil and low-carbon olefins, which is applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, hydrocarbon cracking, etc., can solve the problems of low yield of low-carbon olefins, and achieve simple operation process, wide application range of raw materials, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This example is used to illustrate the method for preparing low-carbon olefins from bio-oil provided by the present invention.

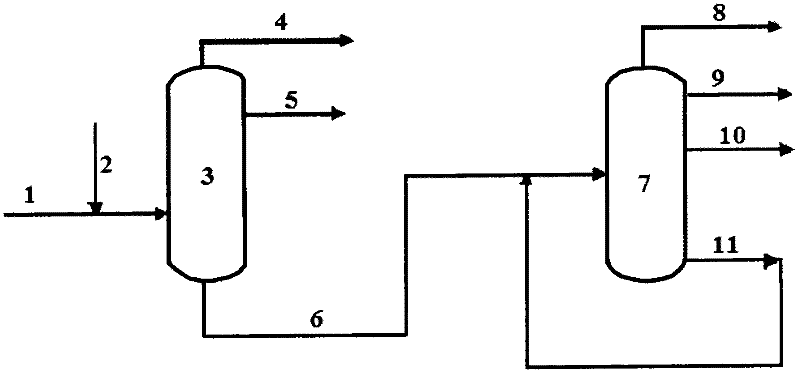

[0041] Such as figure 1 Shown, make palm oil (the content of unsaturated fatty acid ester and unsaturated fatty acid is 44.5% by weight) and the mixture of hydrogen with 10h -1 The volume space velocity passes through the fixed-bed reactor (the filling amount of the hydrogenation catalyst is 30g, and the nickel oxide of 3% by weight, the cobalt oxide of 0.08% by weight, the tungsten oxide of 8% by weight and the tungsten oxide of 88.92% by weight are contained in this hydrogenation catalyst Silica carrier), at a temperature of 200°C and a pressure of 2MPa, the hydrogenation reaction is carried out, and the volume ratio of hydrogen to the palm oil is 70Nm 3 / m 3 . Separate the fat phase from the reaction product, and make the fat phase with 6h -1 The volume space velocity enters the moving bed reactor (the filling capacity of the catalytic ...

Embodiment 2

[0043] This example is used to illustrate the method for preparing low-carbon olefins from bio-oil provided by the present invention.

[0044] The method according to embodiment 1 adopts biogrease to prepare light olefins, the difference is that the heavy oil separated from the reaction product of the moving bed reactor is not returned to the moving bed reactor for further catalytic cracking reaction, so The obtained ethylene yield, propylene yield, butene yield and the total yield of ethylene+propylene+butene are shown in Table 1 below.

Embodiment 3

[0050] This example is used to illustrate the method for preparing low-carbon olefins from bio-oil provided by the present invention.

[0051] Such as figure 1 Shown, make the mixture of rapeseed oil (the content of unsaturated fatty acid ester and unsaturated fatty acid is 90% by weight) and hydrogen with 5h -1 The volume space velocity passes through the fixed-bed reactor (the filling amount of hydrogenation catalyst is 30g, contains the nickel oxide of 4% by weight, the cobalt oxide of 0.1% by weight, the tungsten oxide of 5% by weight, the tungsten oxide of 5% by weight in this hydrogenation catalyst Molybdenum oxide and 85.9% by weight of alumina carrier), at a temperature of 150 ° C, a pressure of 5MPa to carry out hydrogenation reaction, the volume ratio of hydrogen to the palm oil is 50Nm 3 / m 3 . Separate the fat phase from the reaction product, and make the fat phase with 0.2h -1 The volume space velocity enters the moving bed reactor (the filling capacity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com