Method for maximum production of clean diesel oil by shale oil whole fraction hydrogenation

A shale oil, the largest amount of technology, applied in the field of shale oil hydrogenation to produce clean diesel in large quantities, can solve the problems of shortening the operation period of the device, residual oil and coke, etc., to ensure long-term operation, good water resistance, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

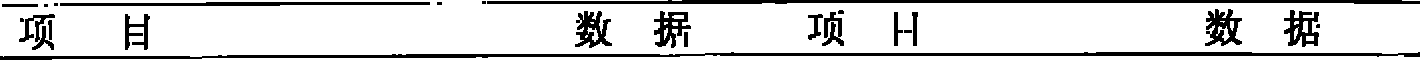

[0029] The properties of the raw oil used in the examples are shown in Table 1.

[0030] Table 1 Properties of whole fractions of shale oil (composition is mass percentage)

[0031]

[0032]

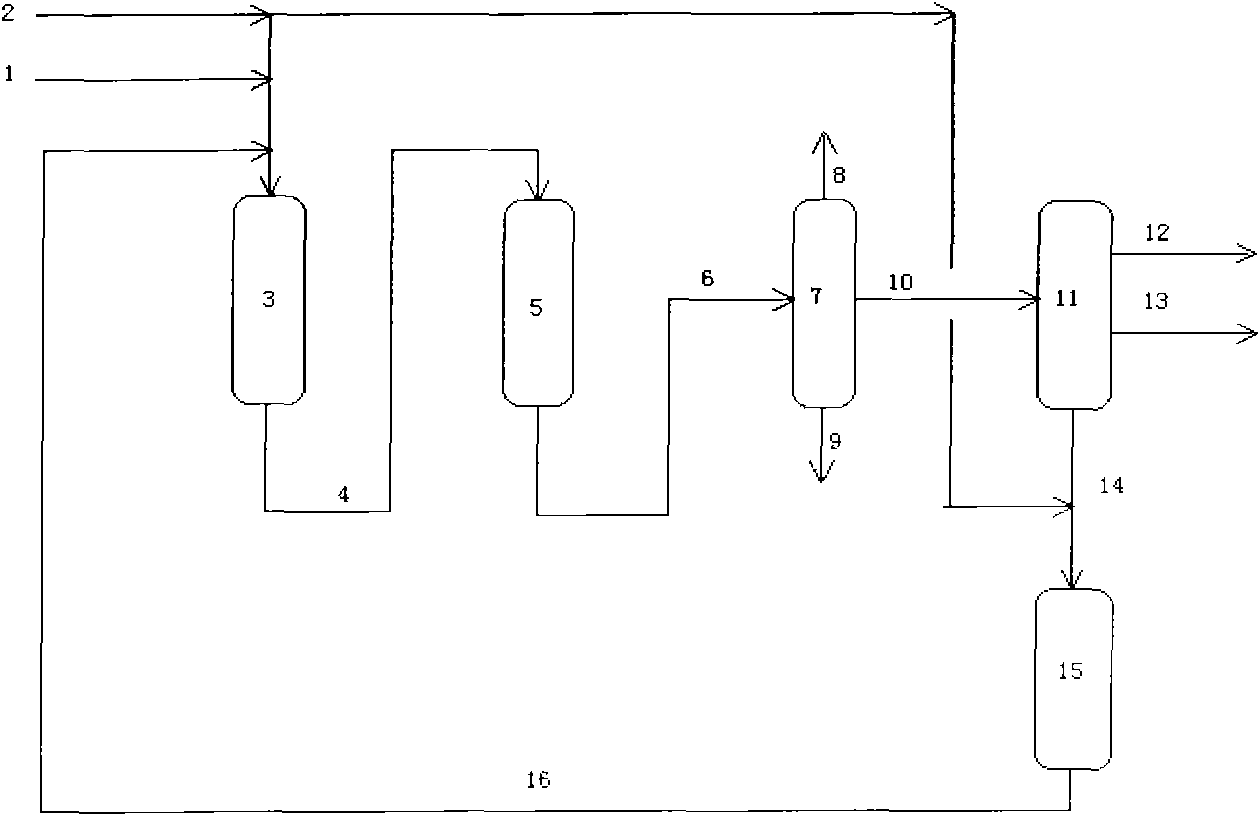

[0033] First, the whole fraction of shale oil is mixed with hydrogen and hydrocracking reaction effluent into the hydrofinishing reactor to obtain hydrofinished oil for separation, and the unconverted oil enters the hydrocracking reactor for hydrocracking, and the obtained hydrogenation All the reaction effluent is returned to the hydrofinishing reactor as the feed for hydrofinishing, and the oil produced by hydrofinishing is obtained for fractionation.

[0034] The first reactor in the hydrofining reaction section is filled with the large-particle hydrotreating catalyst R-FF-26 developed by Fushun Petrochemical Research Institute, which is in the shape of a Raschig ring with a diameter of 10×10mm, and the bed porosity is 0.60. The second reactor is filled with FF-36 hydrotreating c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com