Preparation method of H beta/HMCM-49 compound molecular sieve

A technology of composite molecular sieve and β molecular sieve, which is applied in the field of preparation of Hβ/HMCM-49 composite molecular sieve, can solve the problems not related to the preparation method of Hβ-HMCM-49 composite molecular sieve, and achieve large average pore size, strong total acidity, and through-hole many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

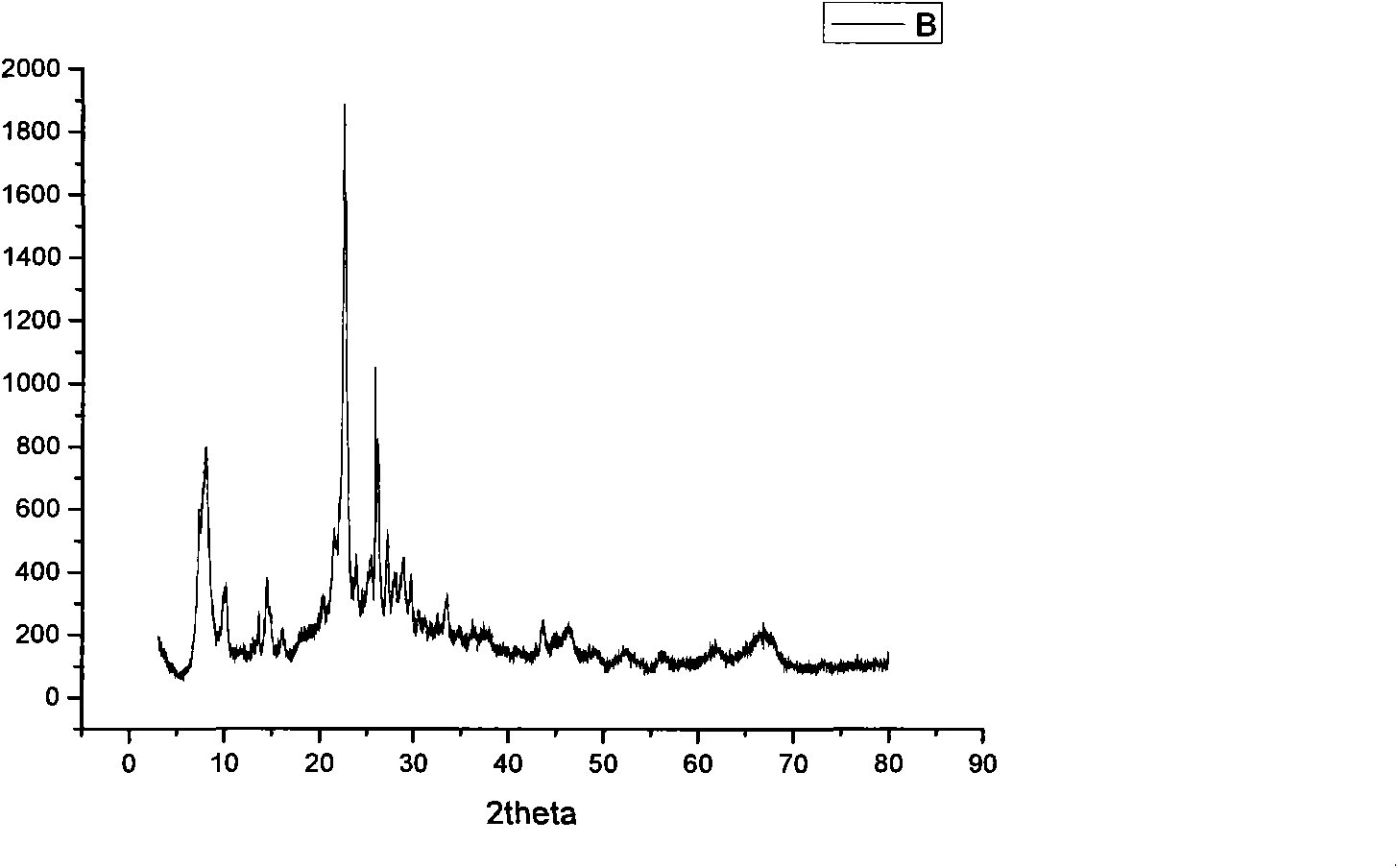

Embodiment 1

[0024] Slurry preparation of Naβ molecular sieve: Add 350ml of distilled water into the gelling kettle, add 32g of sodium metaaluminate, 1.1g of sodium hydroxide, and 2g of potassium hydroxide, and dissolve them completely under stirring to make potassium and sodium metaaluminate aqueous solution. Weigh 170g of tetraethylammonium bromide, add 100ml of water and 200ml of 17% ammonia water, stir to make it completely dissolve, and make a quaternary ammonium salt solution, and add the quaternary ammonium salt solution and potassium metaaluminate sodium alkali solution to the gelling kettle Add 700g of 30% silica sol slowly, then add 2.5g of Naβ molecular sieve raw powder, and gel for 2 hours; then add it to a 1L crystallization kettle, and crystallize at 150°C and 60 rpm 110h, the obtained Naβ molecular sieve slurry.

[0025] Preparation of NaMCM-49 molecular sieve slurry; add 540ml of distilled water to the gelling kettle, add 29g of sodium metaaluminate, and dissolve it comple...

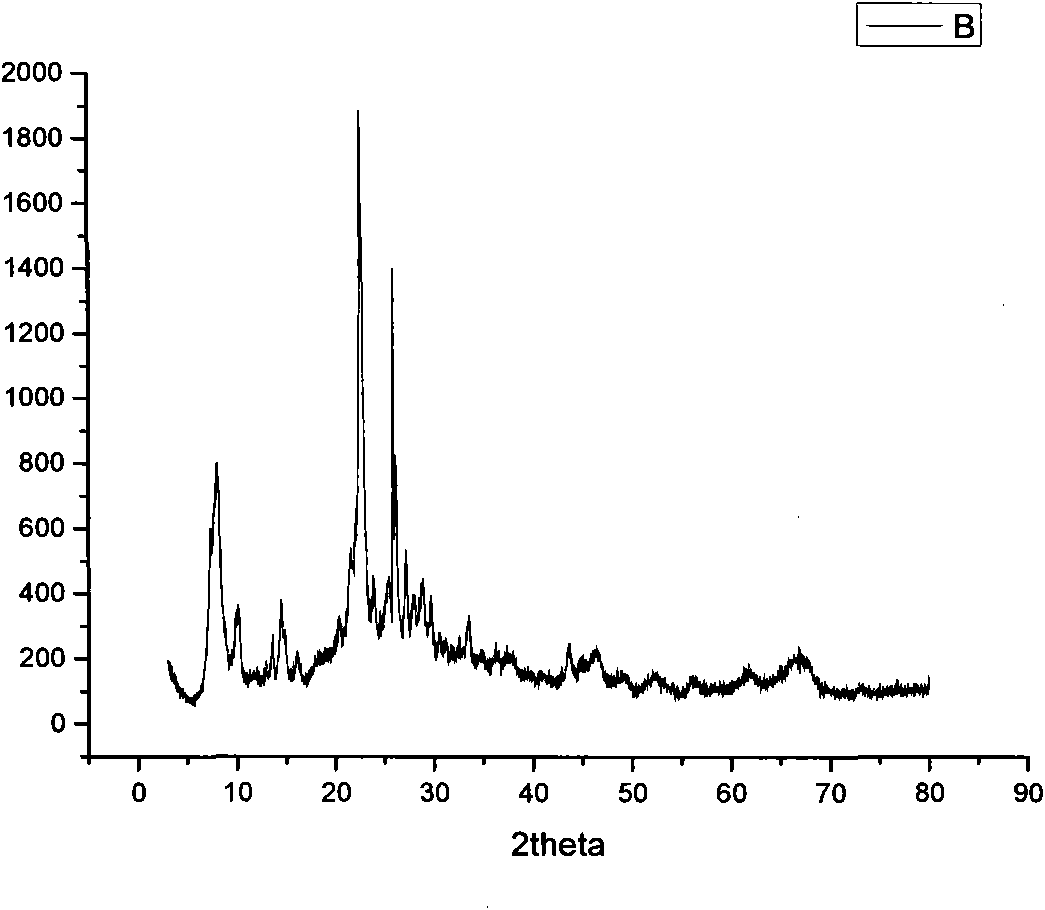

Embodiment 2

[0029] Preparation of Naβ molecular sieve slurry: Add 300ml of distilled water into the gelling kettle, add 30g of sodium metaaluminate, 1.1g of sodium hydroxide, and 0.5g of potassium hydroxide, and dissolve them completely under stirring to make potassium sodium metaaluminate alkaline aqueous solution. Weigh 150g of tetraethylammonium bromide, add 100ml of water and 150ml of 17% ammonia water, stir to make it completely dissolve, and make a quaternary ammonium salt solution, and add the quaternary ammonium salt solution and potassium metaaluminate sodium alkali solution to the gelling kettle and mix evenly; slowly add 700g of 30% silica sol, then add 3.0g of Naβ molecular sieve raw powder, and gel for 2.0h; then add it into a 1L crystallization kettle, and crystallize After 110 h, the slurry of Naβ molecular sieve obtained.

[0030] Preparation of NaMCM-49 molecular sieve slurry; add 540ml of distilled water into the gelling kettle, add 28.6g of sodium metaaluminate, and di...

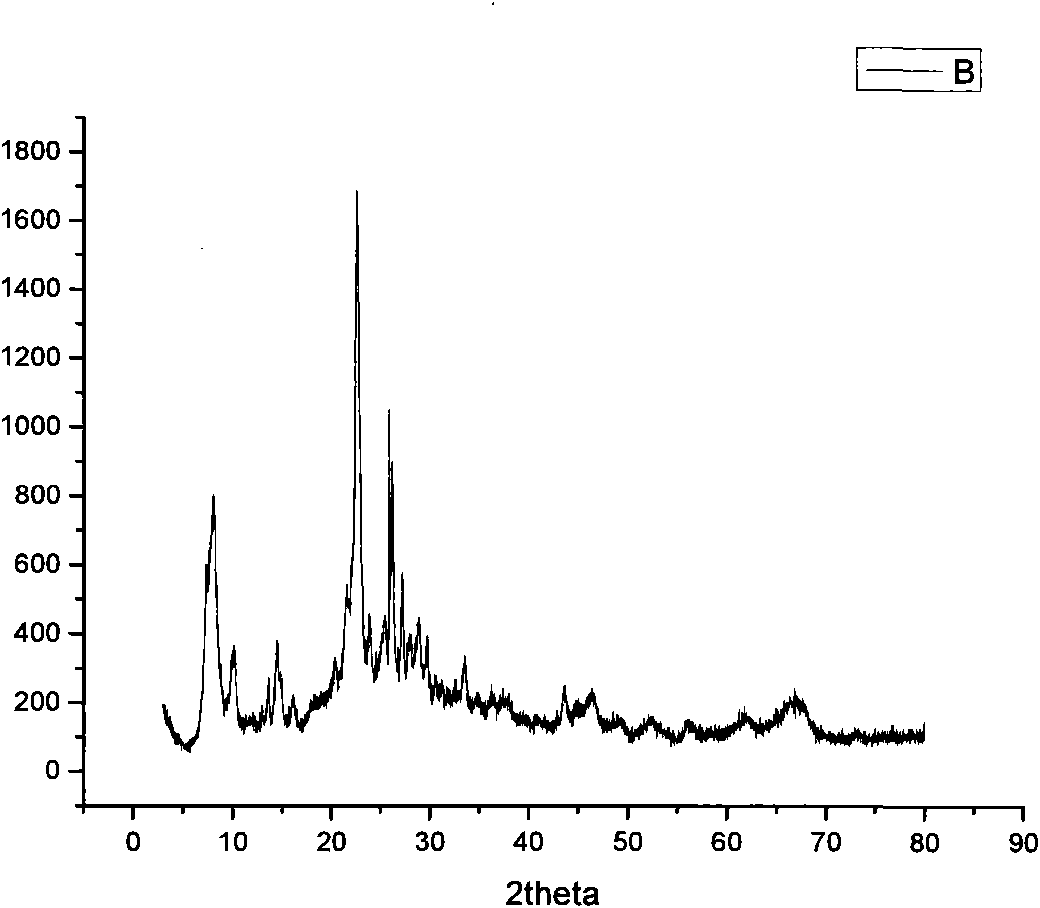

Embodiment 3

[0037] Slurry preparation of Naβ molecular sieve: Add 310ml of distilled water, 30g of sodium metaaluminate, 1.1g of sodium hydroxide, and 0.5g of potassium hydroxide into the gelling kettle, dissolve them completely under stirring, and make potassium sodium metaaluminate base aqueous solution. Weigh 165g of tetraethylammonium bromide, add 100ml of water and 190ml of 17% ammonia water, stir to make it dissolve completely, and make an aqueous solution of quaternary ammonium salt, add this aqueous solution of quaternary ammonium salt and potassium metaaluminate sodium alkali solution to the Add 690g of 30% silica sol slowly, then add 2.5g of Naβ molecular sieve raw powder, and gel for 2.5h; then crystallize for 115h at 152°C and 70 rpm to obtain Naβ molecular sieve of slurry.

[0038] Preparation of NaMCM-49 molecular sieve slurry; add 540ml of distilled water into the gelling kettle, add 28.6g of sodium metaaluminate, and dissolve it completely under stirring; add 120ml of hex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com