Method for pretreating industrial waste water

A technology for industrial wastewater and pretreatment, applied in water/sewage treatment, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc. The effect of reducing sulfate removal rate, improving treatment efficiency and reducing treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

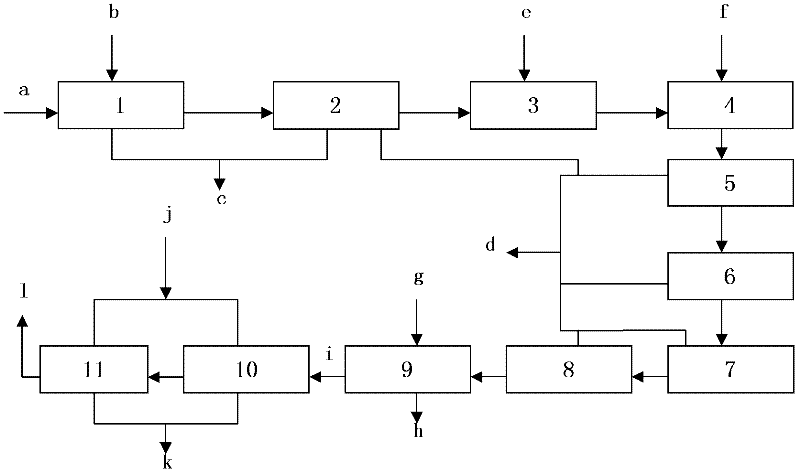

Method used

Image

Examples

Embodiment 1

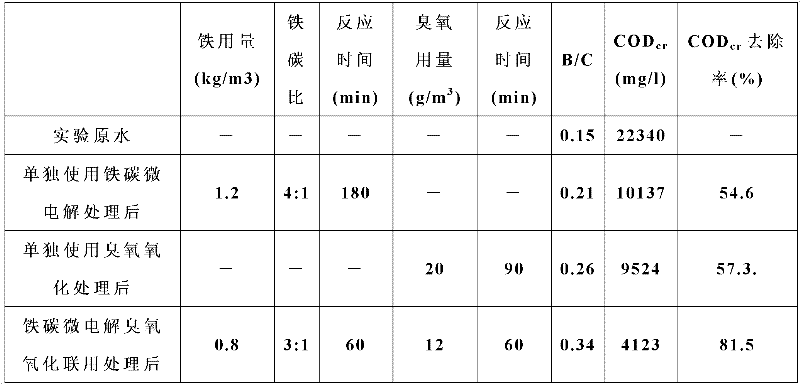

[0030] Take 4000mL of waste water produced in the production process of 7-ADCA (produced by Shandong New Times Pharmaceutical Co., Ltd., production batch number is 11033130), and divide it evenly into four parts, each part is 1000mL. The experimental parameters and treatment results of each treatment group are shown in Table 1, wherein COD cr Measured by dichromate method (GB 11914-89), BOD 5 Measured by dilution and inoculation method (HJ505-2009).

[0031] Table 1: Comparison of parameters control and treatment results of wastewater produced in the 7-ADCA production process by different processes

[0032]

[0033] As shown in Table 1, the results of different wastewater treatment processes, B / C and COD after wastewater treatment using iron-carbon micro-electrolysis process and ozone oxidation process cr The removal rate is not only significantly different from the experimental raw water, but also significantly different from the wastewater treatment effect of the iron-ca...

Embodiment 2

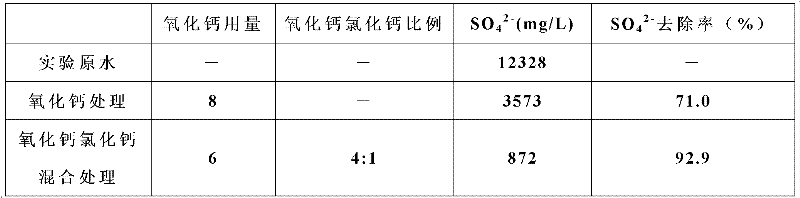

[0035] Take 3000mL of wastewater generated during the production process of 7-ADCA (produced by Shandong New Times Pharmaceutical Co., Ltd., production batch number is 11033130), and divide it into three parts evenly, each with 1000mL. The experimental parameters and treatment results of each treatment group are shown in Table 2, in which SO before and after treatment 4 2- Measured by gravimetric method (GB 11899-89).

[0036] Table 2: Comparison of parameters control and treatment results of wastewater produced in the 7-ADCA production process by different processes

[0037]

[0038] As shown in Table 2, calcium oxide and calcium chloride are used to process wastewater produced in the 7-ADCA production process, and the SO after treatment 4 2- The content of SO is not only significantly different from the experimental raw water group, but also compared with the SO content of industrial wastewater treated with calcium oxide alone. 4 2- content was also significantly red...

Embodiment 3

[0040] The wastewater indicators discharged from a 7-ADCA production workshop are shown in Table 3. Add the iron carbon after soaking and activation to the micro electrolytic cell, and the amount of iron filings is 0.8kg / m 3 , the mass ratio of iron to carbon is Fe:C=4:1. After the wastewater enters, the aeration is turned on, and after 90 minutes of reaction, it is discharged into the sedimentation tank, and the supernatant enters the ozone oxidation tank, and the amount of ozone is 12g / m 3 , The reaction time is 60min. After the reaction, the effluent enters the desulfurization tank, and the dosage of calcium oxide is 6kg / m 3 , Calcium oxide and calcium chloride are added at a mass ratio of 4:1. After the stirring is started and fully mixed, the effluent enters the advection sedimentation tank, radial flow sedimentation tank, sand filter tank and air flotation tank successively. Add sodium hydroxide solution to fine-tune the pH to 9 after air flotation, and then pump it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com