Preparation method and product of hafnium dioxide film on fastener surface

A hafnium dioxide and fastener technology, applied in the field of thin film preparation, can solve the problems of fasteners with no insulation, poor corrosion resistance, large surface roughness, etc., and achieve excellent and complete coverage and firm surface coating. , the effect of simple equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

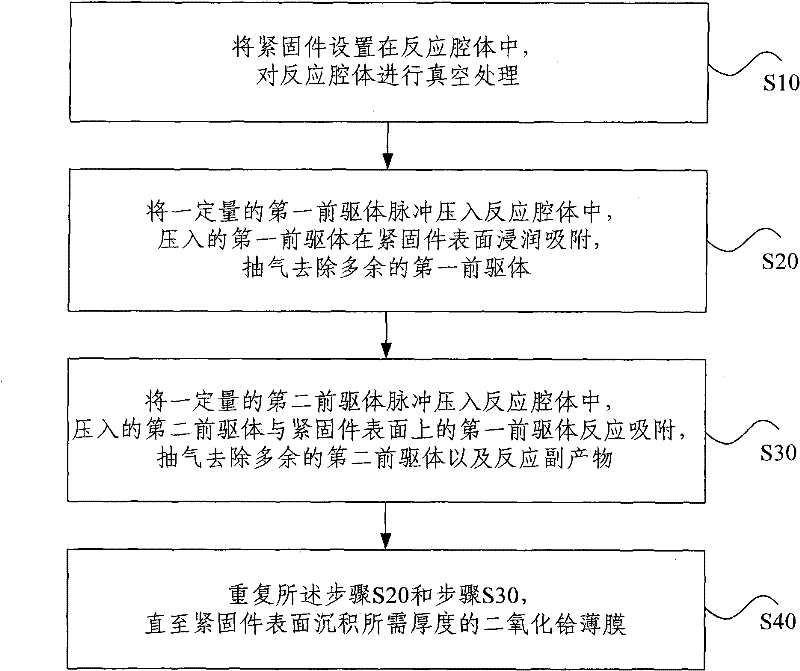

[0034] Such as figure 1 Shown, the preparation method of a kind of fastener surface hafnium dioxide thin film of the present invention comprises:

[0035] Step S10: setting the fastener in the reaction chamber, and vacuuming the reaction chamber; wherein, the temperature of the reaction chamber can be 20-500° C., and the vacuum degree of the reaction chamber can be 1×10 -2 -7×10 -3 Torr.

[0036]Step S20: Pulse pressing a certain amount of the first precursor into the reaction chamber, the pressed first precursor is soaked and adsorbed on the surface of the fastener, and the excess first precursor is removed by pumping; That is, since the reaction chamber has been vacuum-processed, the first precursor is pressed into the reaction chamber due to the pressure difference, and the pulse of the first precursor can be realized by setting a special valve body. The special valve body is a commercially available mature product, and will not be repeated here.

[0037] Step S30: Pul...

Embodiment 1

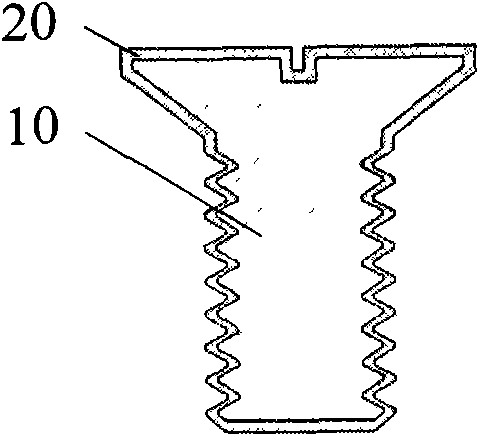

[0060] Such as image 3 As shown, a screw 10 with an outer diameter of 5mm is placed in the reaction chamber of the atomic layer deposition equipment, and the vacuum degree of the reaction chamber is 1×10 -2 Torr, the temperature of the reaction chamber is 20°C, the heating temperature of the hafnium-containing precursor is 20°C, the flow rate of the carrier gas is 50 sccm, and the pulse HfCl 4 Precursor 1S, pumping 20S, then pulse H 2 O precursor 0.1S, pumping for 50S, alternate cycle pulse 10,000 times in sequence to obtain HfO 2 Thin film 20 has a thickness of about 900-1000 nm.

[0061] After the thin film is deposited, the screw 10 not only has the advantages of high strength, high hardness, corrosion resistance, oxidation resistance and high adhesion, but also has good insulation effect.

[0062] In addition, the surface color of the screw 10 is purple.

Embodiment 2

[0064] Such as Figure 4 As shown, a gasket 11 with an inner diameter of 5mm is placed in the reaction chamber of the atomic layer deposition equipment, and the vacuum degree of the reaction chamber is 1×10 -3 Torr, the temperature of the reaction chamber is 250°C, the heating temperature of the hafnium-containing precursor is 75°C, the flow rate of the carrier gas is 10 sccm, and the pulse Hf(NMe 2 ) 4 Precursor 0.02S, pumping 1S, then pulse H 2 O precursor 0.015S, evacuation 1S, alternate cycle pulse 500 times in sequence to obtain HfO 2 Thin film 20 has a thickness of about 45-55 nm.

[0065] After the thin film is deposited, the gasket 11 not only has the advantages of high strength, high hardness, corrosion resistance, oxidation resistance and high adhesion, but also has good insulation effect.

[0066] In addition, the surface color of the gasket 11 is light blue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com