Pitch-based carbon fiber and preparation method thereof

A pitch-based carbon fiber, pitch raw material technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., to achieve the effect of rich source of raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

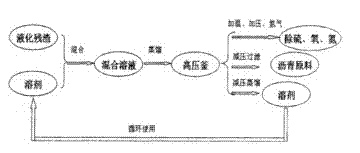

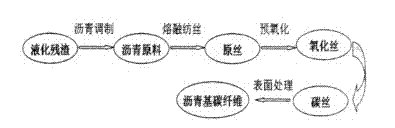

[0036] Grind 10 kg of coal direct liquefaction residue into a powder with a particle size of 0.01-0.3 microns. Fully mix the coal direct liquefaction residue powder with 20 kg tetrahydroquinoline to obtain a mixed solution. Put the mixed solution into an autoclave, replace the air in the autoclave with nitrogen, then heat and pressurize while feeding hydrogen for hydrogenation; remove most of the sulfur, oxygen, nitrogen, etc. contained in the original residue by distillation under reduced pressure element, use vacuum filtration to remove tetrahydroquinoline insoluble matter, recover tetrahydroquinoline solvent through vacuum distillation, and recycle. The asphalt raw material produced in the asphalt preparation process is heated and melted and melt-spun through a spinning machine, and the viscosity of the raw material is controlled at 10Pa during the spinning process. S, the spinning temperature is 350°C, and the raw silk is obtained by melt spinning. The raw silk is in...

Embodiment 2

[0038] Grind 10 kg of coal direct liquefaction residue into a powder with a particle size of 0.0-0.3 microns. Thoroughly mix the coal direct liquefaction residue powder with 30 kg of tetrahydroquinoline to obtain a mixed solution. Put the mixed solution into an autoclave, replace the air in the autoclave with nitrogen, then heat and pressurize while feeding hydrogen for hydrogenation; remove most of the sulfur, oxygen, nitrogen, etc. contained in the original residue by distillation under reduced pressure element, use vacuum filtration to remove tetrahydroquinoline insoluble matter, recover tetrahydroquinoline solvent through vacuum distillation, and recycle. The asphalt raw material produced in the asphalt preparation process is heated and melted and melt-spun through a spinning machine, and the viscosity of the raw material is controlled at 15Pa during the spinning process. S, the spinning temperature is 380°C, and the raw silk is obtained by melt spinning. The raw sil...

Embodiment 3

[0040] 01-0.3微米的粉丝。 1 0 kg of coal direct liquefaction residue ground into a particle size of 0. 01-0.3 micron powder. Thoroughly mix the coal direct liquefaction residue powder with 40 kg of tetrahydroquinoline to obtain a mixed solution. Put the mixed solution into an autoclave, replace the air in the autoclave with nitrogen, then heat and pressurize while feeding hydrogen for hydrogenation; remove most of the sulfur, oxygen, nitrogen, etc. contained in the original residue by distillation under reduced pressure element, use vacuum filtration to remove tetrahydroquinoline insoluble matter, recover tetrahydroquinoline solvent through vacuum distillation, and recycle. The asphalt raw material produced in the asphalt preparation process is heated and melted and melt-spun through a spinning machine, and the viscosity of the raw material is controlled at 18Pa during the spinning process. S, the spinning temperature is 400°C, and the raw silk is obtained by melt spinning. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com