Preparation method of biodegradable polymer microcapsules

A polymer membrane and biological technology, applied in the molding and processing of microcapsule materials, the application of new pharmaceutical preparation materials, and the field of polymer microspheres, can solve problems such as poor spherical shape, complicated preparation process, and uneven pore size distribution, and achieve The process is gentle and avoids damage to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

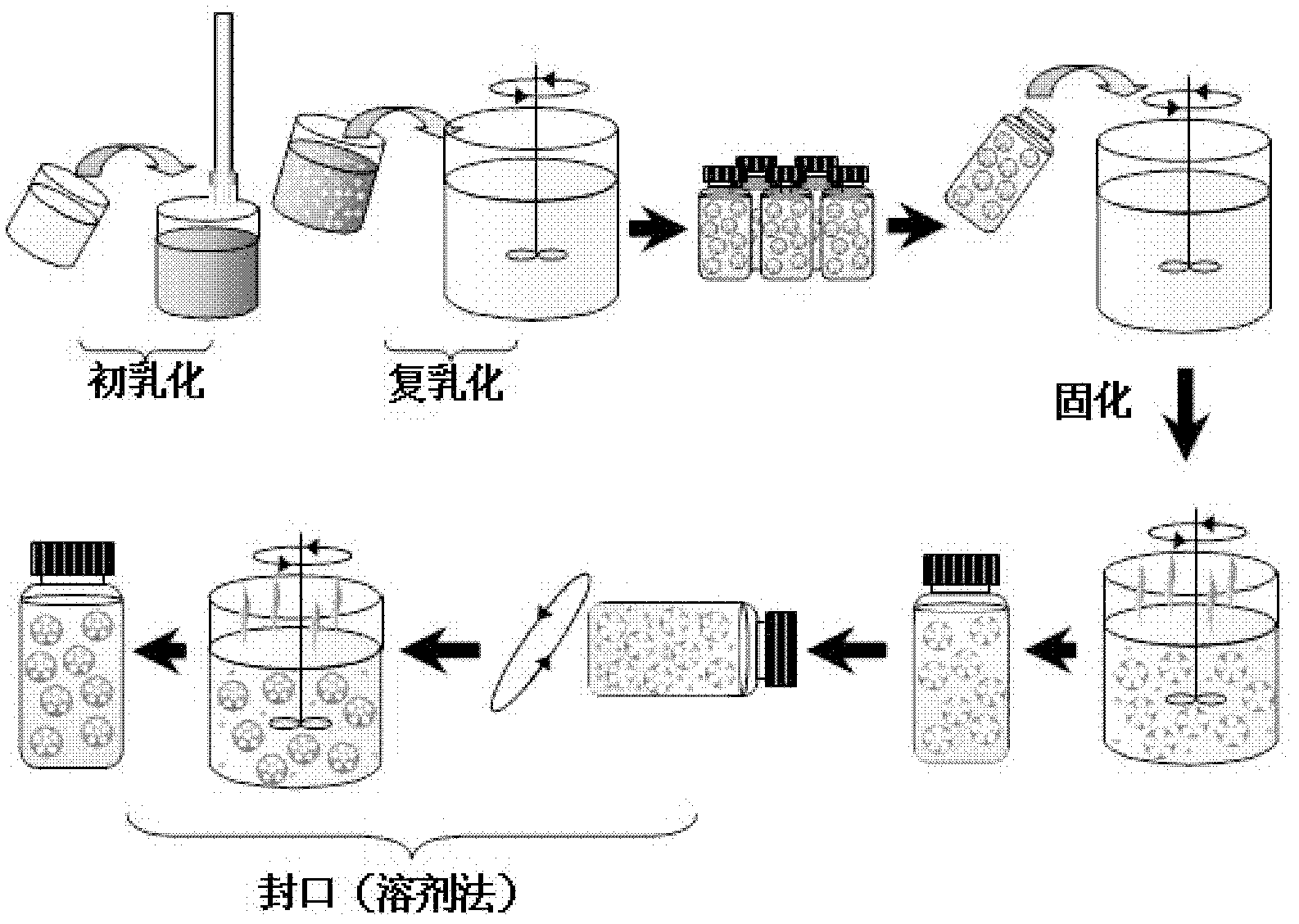

Method used

Image

Examples

Embodiment 1

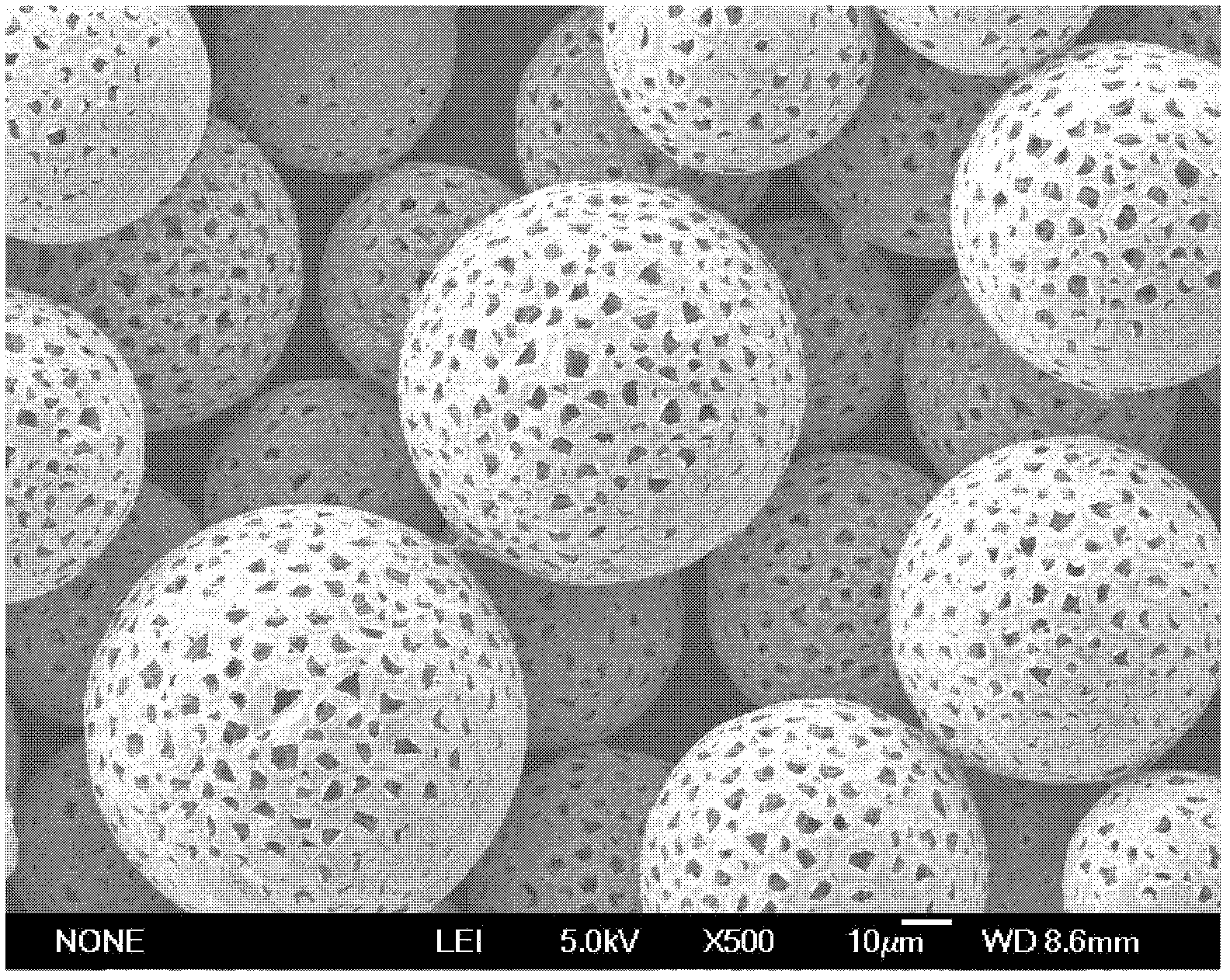

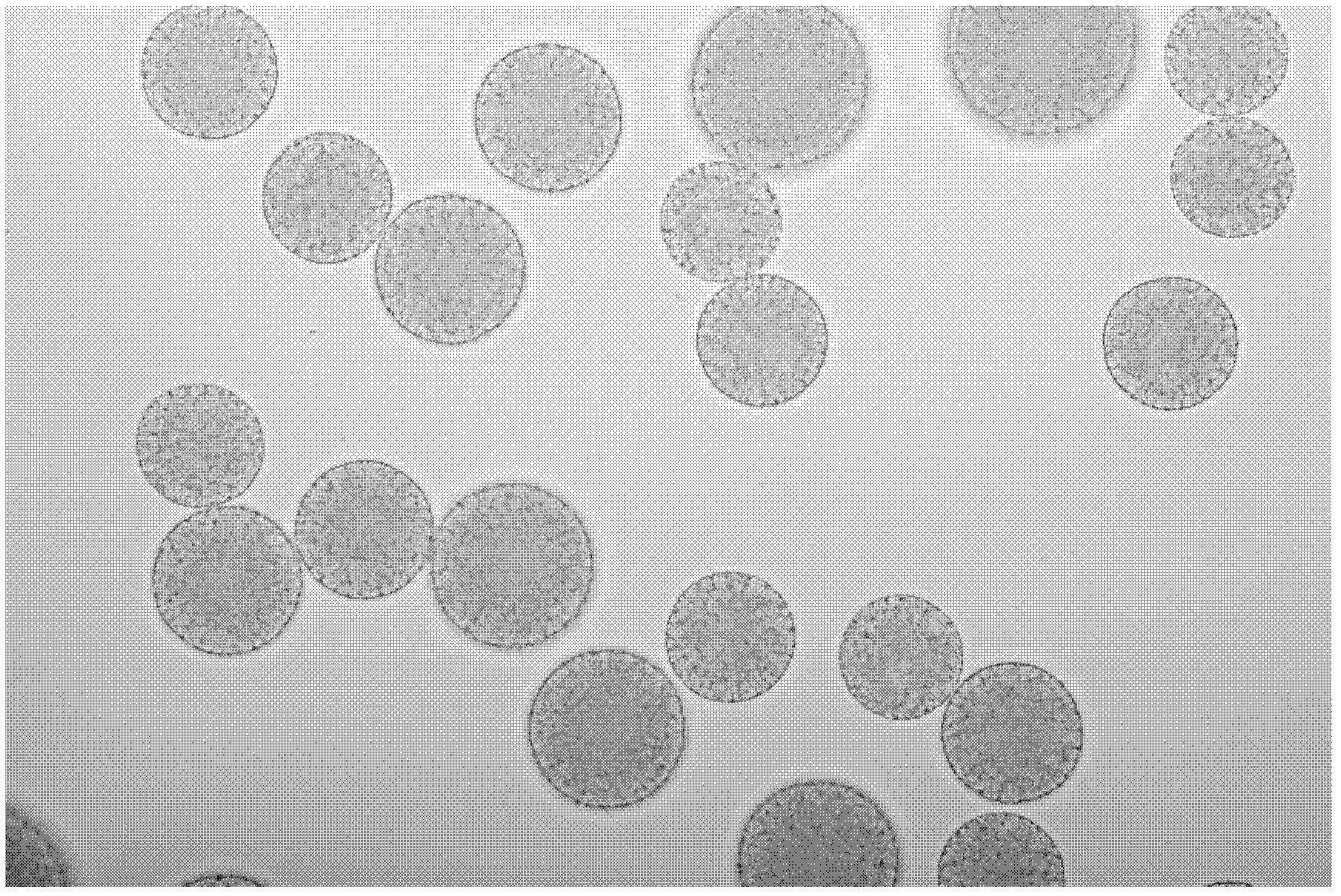

[0093] Take by weighing 200mg PELA and place in test tube, add 2ml ethyl acetate and dissolve it, make oil phase; Prepare 1.0% NaCl (w / v) aqueous solution, as inner aqueous phase; Prepare 2.5% PVA (w / v) aqueous solution and Place in a separatory funnel, add excess ethyl acetate, shake well to make a saturated solution, let stand, remove the clear liquid after layering, add NaCl, and make the NaCl concentration in the saturated solution 0.5% (w / v ) as the external aqueous phase. Take 800 μl of the inner water phase and add it to the oil phase, homogeneously emulsify at 14,000 rpm for 25 seconds to form a primary emulsion; pour the primary emulsion into 15 ml of the outer aqueous phase, and homogeneously emulsify at 4,000 rpm for 60 seconds to form a double emulsion.

[0094] Put the complex emulsion into a reaction bottle, mix it vertically for 10 minutes, remove it, pour it into 10ml of deionized water, and stir it magnetically at 200 rpm for 3 minutes to pre-cure; then pour t...

Embodiment 2

[0099] Weigh 200mg of PELA into a test tube, add 2ml of ethyl acetate to dissolve it, and make an oil phase; prepare 1.5% NaCl (w / v) aqueous solution as the inner water phase. Prepare a 1.0% PVA (w / v) aqueous solution and place it in a separatory funnel, add excess ethyl acetate, shake well to make a saturated solution, let it stand, remove the clear liquid after layering, add NaCl, and make the saturated solution The concentration of NaCl in the medium is 0.5% (w / v), which is used as the external aqueous phase. Take 600 μl of the inner water phase and add it to the oil phase, homogeneously emulsify at 14,000 rpm for 25 seconds to form a primary emulsion; pour the primary emulsion into 15 ml of the outer aqueous phase, and homogeneously emulsify at 4,000 rpm for 60 seconds to form a double emulsion.

[0100] Put the complex emulsion into a reaction bottle, mix it vertically for 20 minutes, take it out, pour it into 10ml of deionized water, stir it magnetically at 200 rpm for 3...

Embodiment 3

[0104] Weigh 200mg of PELA into a test tube, add 2ml of ethyl acetate to dissolve it, and make an oil phase; prepare 2.5% NaCl (w / v) aqueous solution as the inner water phase. Prepare a 1.0% PVA (w / v) aqueous solution and place it in a separatory funnel, add excess ethyl acetate, shake well to make a saturated solution, let it stand, remove the clear liquid after layering, add NaCl, and make the saturated solution The concentration of NaCl in the medium was 1.0% (w / v), which was used as the external aqueous phase. Take 600 μl of the inner water phase and add it to the oil phase, homogeneously emulsify at 14,000 rpm for 25 seconds to form a primary emulsion; pour the primary emulsion into 15 ml of the outer aqueous phase, and homogeneously emulsify at 4,000 rpm for 60 seconds to form a double emulsion.

[0105] Put the complex emulsion into a reaction bottle, mix it vertically for 2 minutes, remove it, pour it into 10ml of deionized water, stir it magnetically at 200 rpm for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com