Method for preparing high-purity silicon powder through microwave plasma torch

A technology of microwave plasma and high-purity silicon powder, applied in chemical instruments and methods, silicon, silicon compounds, etc., can solve the problems of high energy consumption and serious environmental pollution, and achieve the advantages of protecting the environment, fewer process steps, and reducing pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

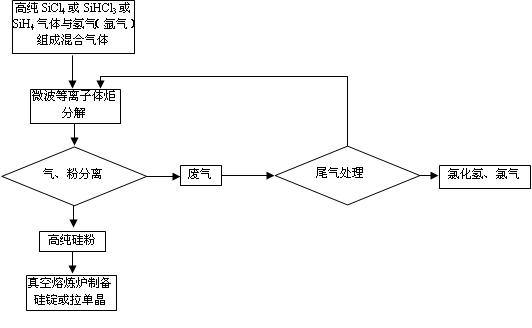

Image

Examples

Embodiment 1

[0018] A method for preparing high-purity silicon powder with a microwave plasma torch:

[0019] The first step: pretreatment: first vacuumize the equipment chamber to 1.8×10 -4 Pa, and then filled with 1 atmosphere of inert gas. High-purity SiCl with a purity of 99.9993% 4 Gas and hydrogen with a purity of 99.92% are uniformly mixed according to the volume ratio of 1:1 to form a mixed gas, and the mixed gas is passed into the discharge chamber of the microwave plasma torch at a flow rate of 500 ml / min through the gas supply pipe, and the pressure in the discharge chamber is 1 Atmospheric pressure, turn on the power supply of the microwave plasma torch, and discharge when the microwave power is 500W to generate a microwave plasma torch;

[0020] Step 2: Preparation of high-purity silicon powder: adjust the power of the microwave plasma torch to 1000W. Under the action of the plasma torch, the mixed gas is decomposed to obtain high-purity silicon powder with a purity of 99.99...

Embodiment 2

[0023] A method for preparing high-purity silicon powder with a microwave plasma torch:

[0024] The first step: pretreatment: first vacuumize the equipment chamber to 1.6×10 -4 Pa, and then filled with 1 atmosphere of inert gas. High-purity SiH with a purity of 99.9991% 4 The gas is uniformly mixed with hydrogen + argon with a purity of 99.93% according to the volume ratio of 1:3 to form a mixed gas, and the mixed gas is passed into the discharge chamber of the microwave plasma torch at a flow rate of 2000 ml / min through the air supply pipe, and the air pressure in the discharge chamber When the pressure is 1 atmosphere, turn on the power supply of the microwave plasma torch, and discharge it when the microwave power is 3000W to generate a microwave plasma torch;

[0025] Step 2: Preparation of high-purity silicon powder: adjust the power of the microwave plasma torch to 3000W. Under the action of the plasma torch, the mixed gas is decomposed to obtain high-purity silicon p...

Embodiment 3

[0028] A method for preparing high-purity silicon powder with a microwave plasma torch:

[0029] The first step: pretreatment: first vacuumize the equipment chamber to 1.5×10 -4 Pa, and then filled with 1 atmosphere of inert gas. High-purity SiClH with a purity of 99.9995% 3 The gas and hydrogen with a purity of 99.94% are uniformly mixed according to the volume ratio of 1:2 to form a mixed gas, and the mixed gas is passed into the discharge chamber of the microwave plasma torch through the gas supply pipe at a flow rate of 1000 ml / min, and the pressure in the discharge chamber is 1 Atmospheric pressure, turn on the power supply of the microwave plasma torch, and discharge when the microwave power is 2000W to generate a microwave plasma torch;

[0030] Step 2: Preparation of high-purity silicon powder: adjust the power of the microwave plasma torch to 2000W. Under the action of the plasma torch, the mixed gas is decomposed to obtain high-purity silicon powder with a purity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com