Nuclear power concrete additive and preparation method thereof

A concrete admixture and admixture technology, applied in the field of nuclear power concrete, to achieve the effects of long pouring time, large amount of concrete, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

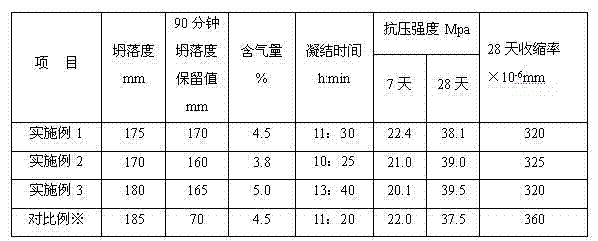

Examples

Embodiment 1

[0029] Escin polycarboxylic acid water reduction agent 40% Ergetic polycarboxylic acid retirement slice 20% Sodium glucose 4% Biological glue 0.1% Triethanolamine 3% Polyethylin induction agent 0.5% benzoic acid 0.1% Polyethylene foaming agent 0.5% water Make it 100%

[0030] Mix the above -mentioned quality percentage raw materials to get the product feasible.

Embodiment 2

[0032] Escin polycarboxylic acid water reduction agent 50% Ergetic polycarboxylic acid retirement slice 10% Citric acid 3% Diethanolamine 10% Saponin 0.2% Sterilizer 0.3% Polyethylene foaming agent 0.5% water Make it 100%

[0033] Mix the above -mentioned quality percentage raw materials to get the product feasible.

Embodiment 3

[0035] Escin polycarboxylic acid water reduction agent 55% Ergetic polycarboxylic acid retirement slice 10% sucrose 4% Hydroxypropylmethylcellulose 0.5% Diethanolamine 10% Saponin 0.1% Polyethylene foaming agent 0.5% water Make it 100%

[0036] Mix the above -mentioned quality percentage raw materials to get the product feasible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com