Repairing method of carbon ceramic brake-disc coating

A brake disc and carbon ceramic technology, which is applied in the field of carbon ceramic brake disc coating online repair, can solve the problems of surface coating damage, affecting the protective effect of the coating, restricting online repair behavior, etc., achieving simple process, preventing oxidation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

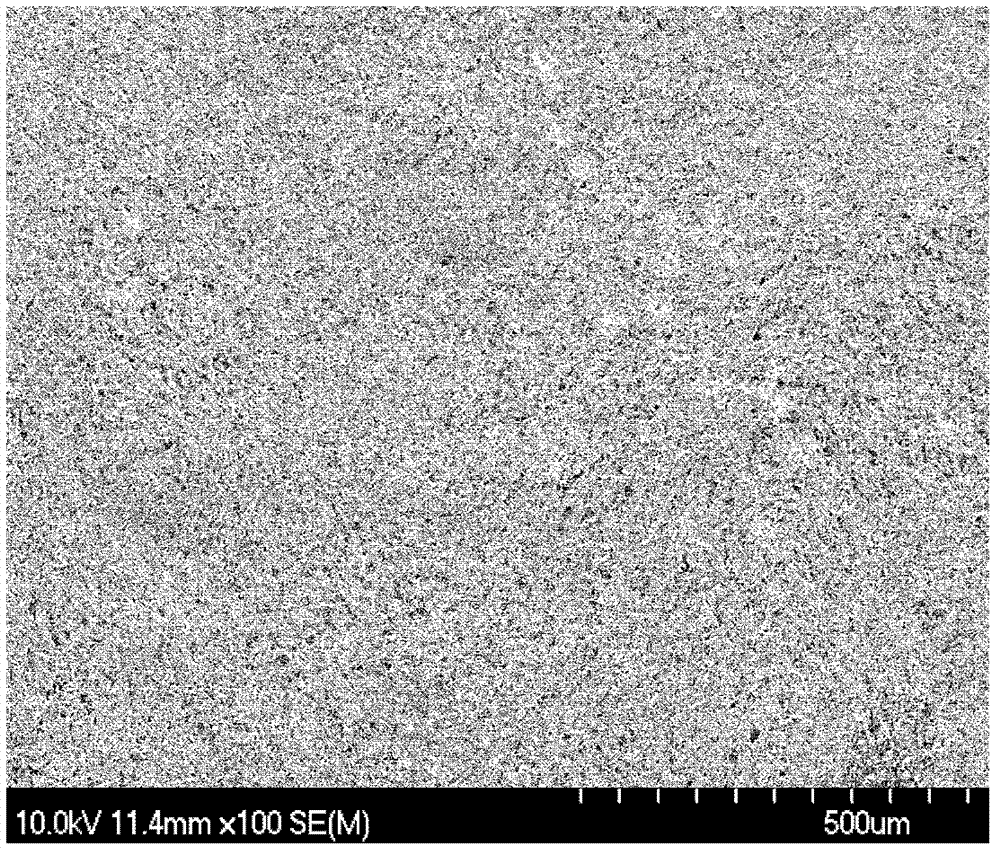

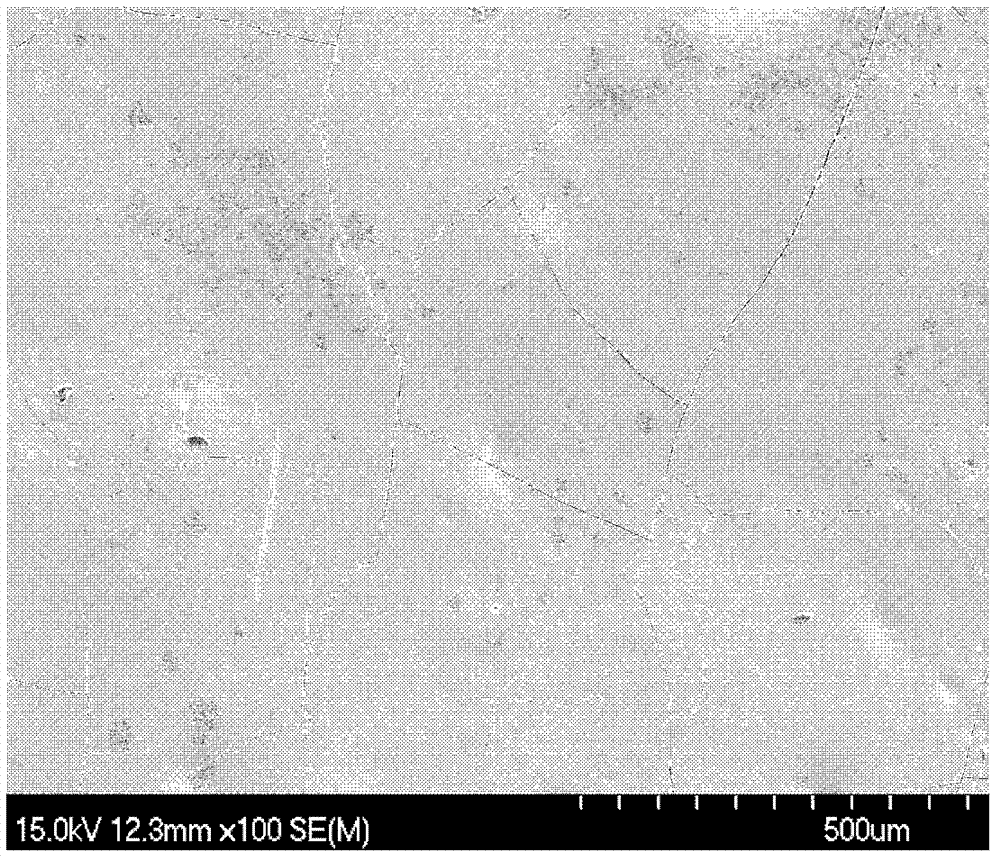

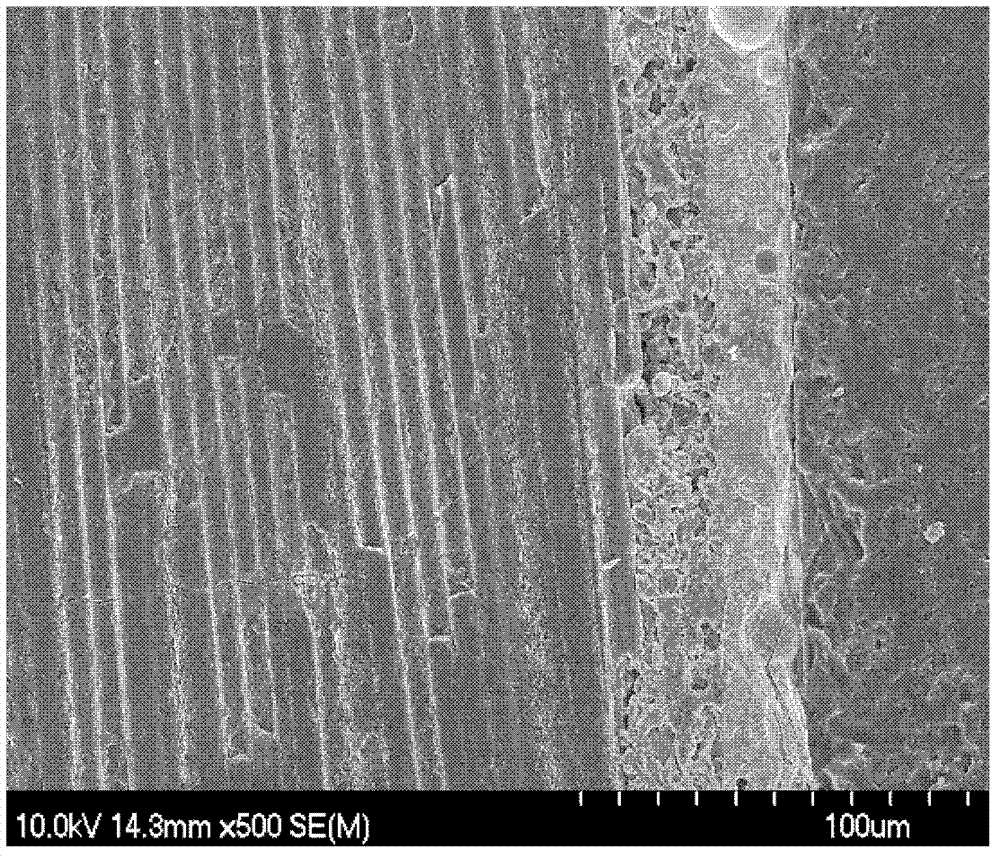

Image

Examples

Embodiment 1

[0031] Step 1: Ultrasonic cleaning of the carbon ceramic brake disc material to be repaired with clean water for 30 minutes, then placed in an oven at 100°C for 30 minutes to dry, and then used;

[0032] Step 2: Add 80-100% ethanol as a solvent to B-Si glass powder, add 15-25% polyazide as a binder, add 15-25% aluminum hydroxide as a solid filler, and ball mill for about 10 -15min to obtain a uniformly mixed slurry;

[0033] Step 3: Brush the uniformly mixed slurry on the surface of the substrate, and cure it for about 5-6 hours at 120°C (infrared lamps can be used on site), so as to obtain the inner coating;

[0034] Step 4: Add 80-100% ethanol as a solvent to Bi glass powder, add 15-25% polyazide as a binder, and ball mill for about 10-15 minutes to obtain a uniformly mixed slurry;

[0035] Step 5: Brush the uniformly mixed slurry on the inner coating prepared in steps 2 and 3, and cure it completely at 120°C (infrared lamps can be used on site) for about 5-6 hours to obtai...

Embodiment 2

[0040] Step 1: Ultrasonic cleaning of the carbon ceramic brake disc material to be repaired with clean water for 30 minutes, then placed in an oven at 100°C for 30 minutes to dry, and then used;

[0041] Step 2: Add 80-100% ethanol to B-Si glass powder as a solvent, add 15-25% polysiloxane and polysiloxane (mass ratio is 1:1) as a binder, add 15-25 % aluminum hydroxide as a solid filler, ball milled for about 10-15 minutes to obtain a uniformly mixed slurry;

[0042] Step 3: Brush the uniformly mixed slurry on the surface of the substrate, and cure it for about 5-6 hours at 120°C (infrared lamps can be used on site), so as to obtain the inner coating;

[0043] Step 4: Add 80-100% ethanol to Bi glass powder as a solvent, add 15-25% polysiloxane and polysiloxane (mass ratio is 1:1) as a binder, and ball mill for about 10-15min, Obtain a homogeneous slurry;

[0044] Step 5: Brush the uniformly mixed slurry on the inner coating prepared in steps 2 and 3, and cure it completely a...

Embodiment 3

[0049] Step 1: Ultrasonic cleaning of the carbon ceramic brake disc material to be repaired with clean water for 30 minutes, then placed in an oven at 100°C for 30 minutes to dry, and then used;

[0050] Step 2: Add 80-100% ethanol as solvent to B-Si glass powder, add 20% polycarbosilane as binder, add 15-25% aluminum hydroxide as solid filler, and ball mill for about 10-15min , to obtain a uniformly mixed slurry;

[0051] Step 3: Brush the uniformly mixed slurry on the surface of the substrate, and cure it for about 5-6 hours at 120°C (infrared lamps can be used on site), so as to obtain the inner coating;

[0052] Step 4: Add 80%-100% ethanol as a solvent to Pb glass powder, add 20% polycarbosilane as a binder, add 15-25% aluminum hydroxide as a solid filler, and ball mill for about 10-15min. Obtain a homogeneous slurry;

[0053] Step 5: Brush the uniformly mixed slurry on the inner coating prepared in steps 2 and 3, and make it completely cured after about 10-12 hours at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com