Environmentally-friendly low-smoke zero-halogen flame-retardant TPEE polyester elastomer cable material and preparation method thereof

A polyester elastomer and polyolefin elastomer technology, applied in the field of elastomer cable material and its preparation, can solve the problems affecting the application field of TPEE polyester elastomer, and achieve safe and reliable production process, excellent mechanical properties, high resistance to high/ Strong low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

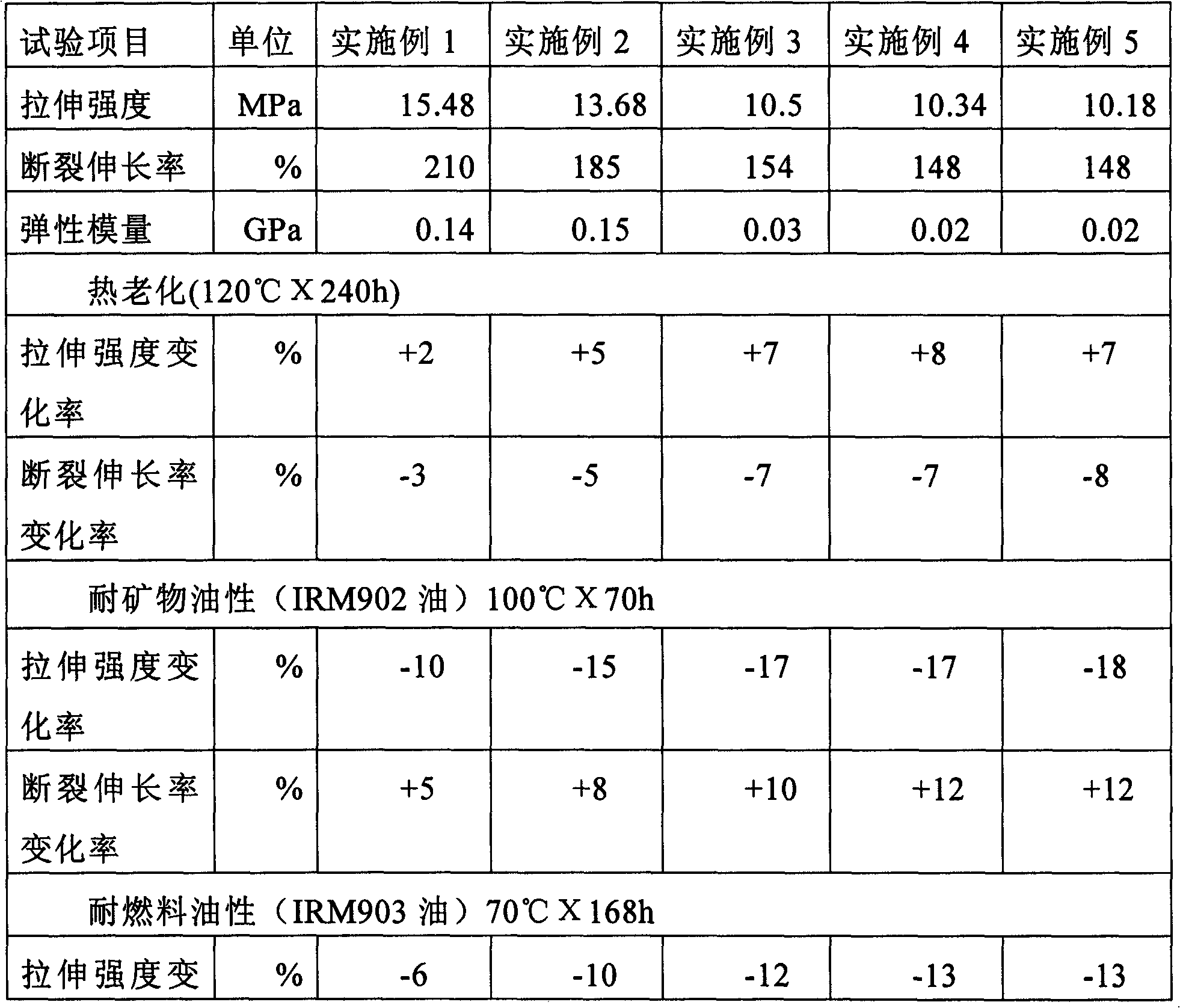

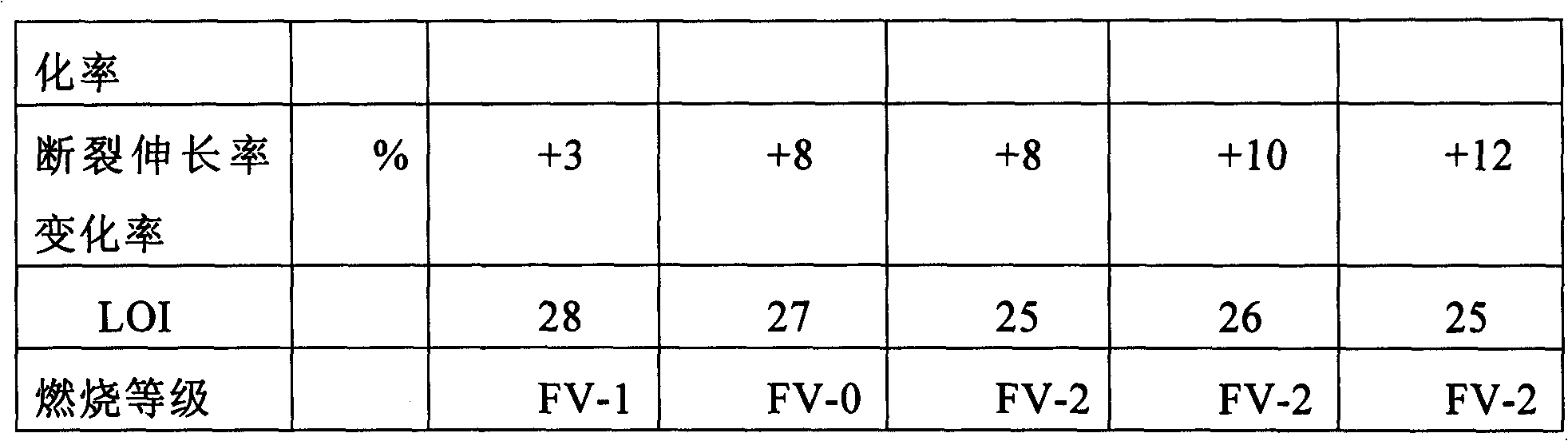

Examples

Embodiment 1

[0032] Polyester elastomer TPEE25kg, DF8402.5kg, phosphate ester flame retardant M-102A 10kg, zinc borate 5kg, ethylene bis-stearic acid amide 0.3kg, tetra[3-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionic acid] pentaerythritol 0.2kg and tris(2,4-di-tert-butyl phenyl ester) 0.1kg were added in a high-speed mixer and mixed evenly, granulated with a twin-screw extruder, and extruded. The temperature of each section of the machine starts from the feeding port, and it is 150-160°C, 175-190°C, 190-200°C, 200-210°C, 210-220°C, 210-220°C, and the head temperature is 210-225°C.

Embodiment 2

[0034] Polyester elastomer TPEE25kg, DF8402.5kg, phosphate ester flame retardant M-102A 10kg, melamine 3kg, zinc borate 3kg, ethylene bis-stearate amide 0.2kg, calcium stearate 0.1kg, polyethylene wax 0.1 kg, 0.1 kg of octadecyl β(3'5'-di-tert-butyl-4'-hydroxyphenyl)propionate and 0.05 kg of tris(2,4-di-tert-butylphenyl ester) phosphite, add high speed After mixing evenly in the mixer, granulate with twin-screw extruder. The temperature of each section of the extruder starts from the feeding port, and it is 150-160°C, 175-190°C, 190-200°C, 200-210°C, and 210-220°C. ℃, 210~220℃, head temperature 210~225℃.

Embodiment 3

[0036] Polyester elastomer TPEE25kg, DF8402.5kg, phosphate ester flame retardant M-102A 8kg, melamine urate MCA 4kg, fumed silica 2.5kg, ethylene bis-stearic acid amide 0.2kg, calcium stearate 0.1kg, polyethylene wax 0.1kg, tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol 0.1kg and tris(2,4-di-tert-butylphenyl phosphite) base) 0.05kg, 1,2-[β-(3,5-di-tert-butyl-4-hydroxy)phenyl]propionyl hydrazide 0.05kg, added to a high-speed mixer and mixed evenly, granulated with a twin-screw extruder, The temperature of each section of the extruder starts from the feeding port, which is 150-160°C, 175-190°C, 190-200°C, 200-210°C, 210-220°C, 210-220°C, and the head temperature is 210-225°C .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com